Applications of Single Drum Vibratory Rollers in Road Construction

Single drum vibratory rollers keep deep soil and aggregate compaction, high efficiency, and have been spread across many kinds of projects due to their versatility in modern road construction. The use of these machines is the guarantee of longer, more durable roads as they optimum compact base and sub-base materials, and thus, they are the most necessary equipment for both highway expansions and rural road upgrades.

Everything to know about Single Drum Vibratory Rollers

By single drum vibratory roller the road and highway construction is the main target where these units deliver focused and potent compaction by executing a combination of dynamic vibration with substantial weight. This fusion results in the densification of the layers beneath which is a must for stable roadways. The front steel drum along with rear rubber tires, allow the users to have a better grip and if the terrain is a bit difficult the rollers can be moved easily. So, these rollers are great for extended roadwork, small repair works, and also landscaping jobs.

Mainly Applications of Single Drum Vibratory Roller in Road Construction

Single drum vibratory rollers have the scope of several critical phases in road construction where they can offer a dramatic advantage:

- Sub-grade Preparation: By compacting the soil of the sub-grade the machines become the foundation for the project, issue of settlement are prevented, and stability for the layers is secured.

- Base Layer Compaction: Gravel and crushed stone are examples of the materials that once compacted by the rollers become a dense, stable base capable of heavier loads and thus, the pavement life extends.

- Asphalt Surface Finishing: The contribution of single drum units to the attainment of smooth, defect-free asphalt layers during the preliminary phase passes is very limited and thus, the main work is left to double drum rollers.

Bullet Points: Key Benefits

- Perfectly compact granular soils, gravel, and sand with minimum voids and thereby road wear is delayed greatly.

- Improve density and strength of layers which result in roads having a longer life span even under heavy vehicular traffic and bad weather conditions.

- Make operations cost-effective by being simple in maintenance and having lower total cost of ownership as compared to complicated double drum units.

Technical Features and Compaction Mechanism

One of the main reasons of the success of the single drum vibratory roller in compaction is the use of the machine pressure together with the mechanical vibration:

- Vibration Frequency Adjustment: The concerned worker is allowed to adjust the vibration frequency and amplitude in the way best suited for the soil type so as to ensure maximum compaction and at the same time prevent the substrate from being damaged.

- Heavy Drum and Intelligent Weight Distribution: These machines generally weigh between 8 and 20 tons and the closest point to the ground, that is the drum, is where all the force is concentrated for the purpose of deep compaction.

- Sturdy Frame and Traction Management: With the help of the rear tires the unit is capable of moving over uneven and soft areas while the quality of compaction remains at a high level.

Bullet Points: Technical Highlights

- By amplitude and frequency settings the material densities will be ready for the compaction that is going to be carried out.

- Option of a smooth drum or a padfoot drum can be used for granular or cohesive soils respectively which leads to more extensive utilization scenarios.

- On advanced models, the mode change can be done very quickly for better efficiency on mixed projects.

Specialized Real-Time and Jobsite Advantages

Single drum vibratory rollers are not only capable of performing well in different situations as they can be extremely beneficial in certain niche scenarios besides being major roadbuilding instruments:

- Rural and Access Roads: In these places where it is either remote or the soil is soft their walk-on ability and grip are the most valuable factors that at the same time lead to less maintenance because maneuverability and continuous compaction.

- Site Preparation: Prior to road construction, rollers employed on building pads, embankments, and landscaping bases make the infrastructures more stable through the resultant firm ground.

- Rehabilitation and Resurfacing: Rollers facilitate local repair and overlay projects by ensuring the correct bond and compaction of the new materials.

Bullet Points: Real-Time Examples

- Perfect for the compaction of access roads and parking lots located in industrial and residential areas.

- Offer surface preparation at its best for large-scale public works and small-scale landscaping projects.

- Good to be used for soil stabilization, embankment compacting, and substrate preparation before major roadworks.

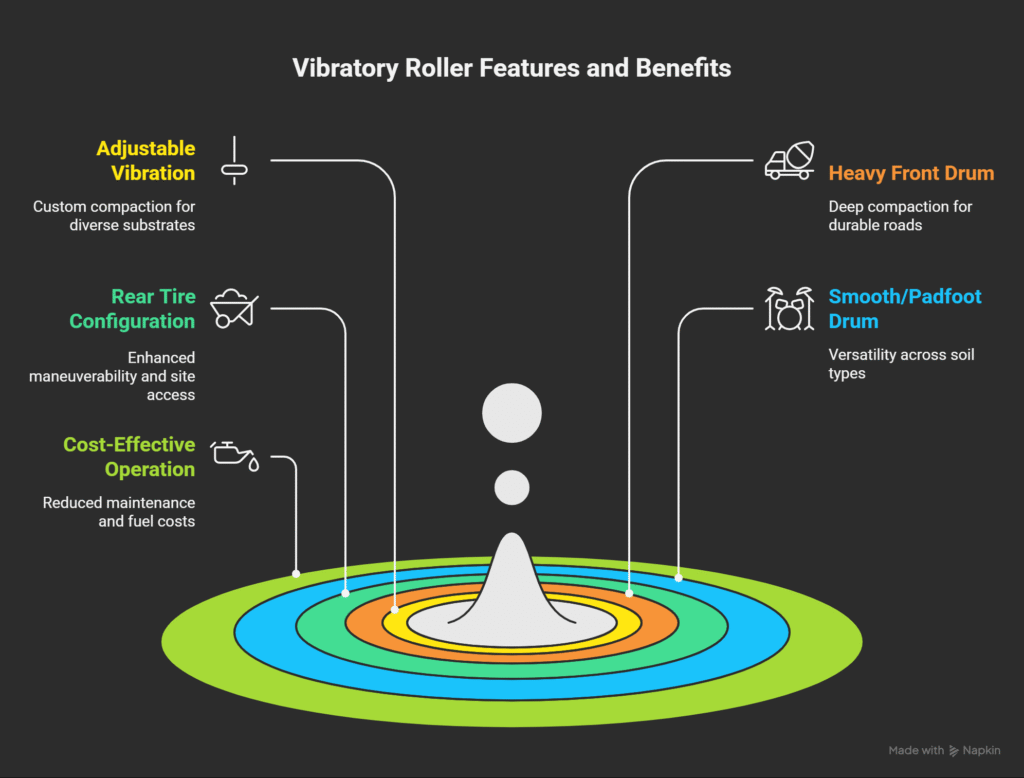

Table: Single Drum Vibratory Roller Key Features

| Feature | Benefit | Project Phase | Suitable Material |

| Adjustable vibration frequency | Custom compaction for varying substrates | All | Soil, gravel, sand |

| Heavy front drum | Deep compaction, longer-lasting roads | Sub-base, base | Granular materials |

| Rear tire configuration | Improved maneuverability and site access | Access roads, prep | All |

| Smooth/padfoot drum options | Versatility across soil types | Site prep, finishing | Cohesive/granular |

| Cost-effective operation | Lower maintenance, fuel, and labor costs | Full project cycle | All |

Environmental and Economic Impact

- Using single drum vibratory rollers is a way of achieving both sizable savings and environmental benefits:

- By maximizing compaction efficiency they are the reason for the reduction in the material that is required, which in its turn leads to less material wastage.

- The fuel that is needed for a certain area of land to be compacted is less when these precise machines are used, thus, the carbon footprint is lower, which is a plus for the environment.

The limited number of passes that thoroughly compact an area resulting in faster timeframe of the projects and labor costs reduction are the benefits most over the road construction site.

Bullet Points: Eco-friendly and Cost Advantages

- Facilitate environmentally friendly construction by lessening the requirement of chemical stabilizers.

- Limit emissions and equipment wear through shorter jobsite durations and reduced unnecessary reworks.

- Help green certification objectives to be achieved by construction projects looking for eco-friendly solutions.

Table: Comparing Single Drum vs. Double Drum Rollers

| Aspect | Single Drum Vibratory Roller | Double Drum Roller |

| Typical Use | Soil/base compaction | Asphalt finishing |

| Maneuverability | High (good for tight spaces) | Moderate (better for open roads) |

| Surface Adaptation | Uneven/rough terrain | Flat, even surfaces |

| Versatility | High (soil, gravel, access) | Focused (asphalt, road topping) |

| Initial Cost | Lower | Higher |

Safety, Operation, and Maintenance

Single drum vibratory rollers for safe operation and optimal results should:

- Matching vibration settings to soil conditions at the site is a must if over-compaction is to be avoided.

- Always check for wear or potential breakdown of the drums, hydraulic systems, and vibration mechanisms and maintain them regularly.

- Correct speed, drum engagement, and troubleshooting procedures should be part of the operator training to productivity be at the maximum and time for downtime be at the minimum.

Bullet Points: Best Practices

- Before the shift fluid levels, tire pressure, and drum settings should be checked as a part of preparations.

- The right traveling speeds ensuring the even compaction of the working area must be the operator’s decision.

- All maintenance events should be documented for compliance and warranty purposes.

Advanced Trends and Future Innovations

- The progresses of roller technology are continuous and they have been changing the efficiencies of road construction over the years:

- Today rollers come with telematics and on-board compaction measurement which offers real-time quality control and reporting.

- To lessen even more the pollutants and fuel consumption, the hybrid and electric-drive models are soon to be there.

- Increasingly standard automated vibration adjustment is there to help the operator in his compaction work and less intervention is required.

FAQs on Single Drum Vibratory Rollers

What makes single drum vibratory rollers essential for road construction?

Single drum vibratory rollers deliver deep and efficient compaction, ensuring stable, long-lasting roads at lower operating costs.

Can a single drum vibratory roller be used for both soil and asphalt?

Yes, although they are optimized for base and sub-base soil compaction, they can make initial passes over asphalt but are less suited than double drum units for final surfacing.

How does the vibration mechanism enhance compaction?

The vibrating action rearranges soil particles, maximizing density and minimizing voids, resulting in stronger, more resilient road layers.

What factors determine the choice between single and double drum rollers?

Key criteria include the type of material, project scale, desired finish, and site constraints—single drum models excel in dense soils and smaller spaces, while double drum rollers specialize in asphalt surfacing over larger, open areas.

What maintenance tasks are most critical for reliable operation?

Most important are regular drum inspections, hydraulic fluid checks, vibration system maintenance, and following the manufacturer’s service schedule which ensure long-lasting performance.

Are single drum vibratory rollers environmentally friendly?

They promote green construction by reducing the need for chemical stabilizers and supporting lower fuel consumption through higher compaction efficiency.

How do single drum vibratory rollers contribute to project economics?

Single drum vibratory rollers accomplish this by reducing labor hours, cutting down rework, and speeding up project timelines, thus they lower the construction costs and increase the overall ROI.

For more detailed manuals, applications of single drum vibratory roller, and the latest on equipment specifications, please refer to rollercompactor.net a platform that provides insights tailored to the construction industry’s needs.