Roller Compactors with Spikes

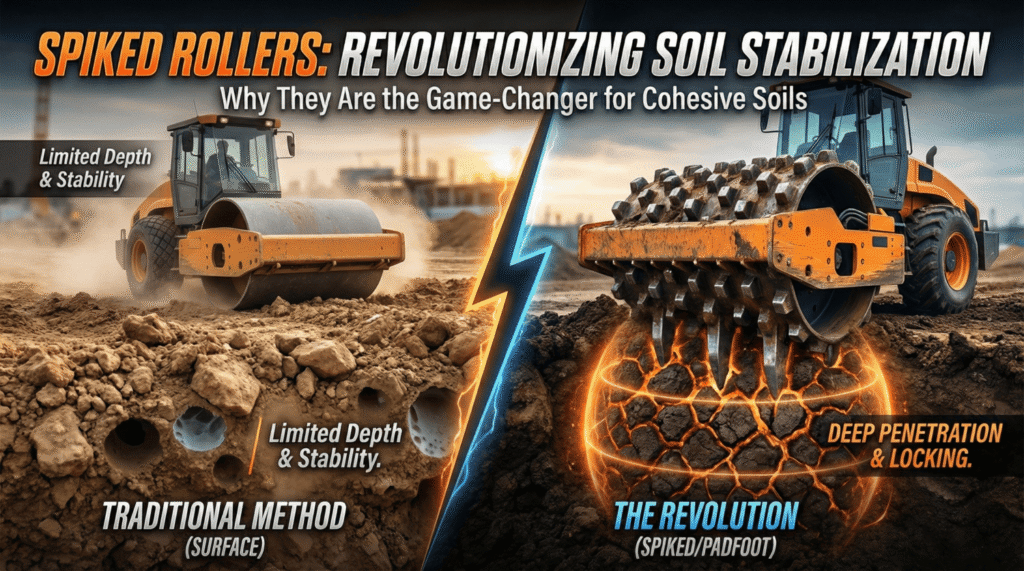

Soil stabilization plays a vital role in the success of any infrastructure project. Whether constructing a large highway, an earthen dam, or a foundation for a commercial building, it is the soil that determines the durability of the structure. From weight and vibration alone, standard compaction methods often struggled with cohesive soils that trap air and resist settling. This is where the industry is witnessing a major change.

The introduction and the use of Roller Compactor with spikes are changing the way builders deal with tough ground. Such machines, in general, can be considered padfoot or sheepsfoot rollers; they are not simply altering the surface; they are essentially changing the density and strength of the soil formation. Instead of merely resurfacing, these rollers penetrate deeper and thus resolve the problems caused by poor soil preparation that lead to settling, shifting, and structural failure.

A roller compactor with spikes is the best solution to those issues that smooth drum rollers cannot be expected to fix. The use of time is money and the need for more productivity are the two key factors of heavy construction. Trying to achieve the specified density of clay or silt using conventional methods normally necessitates many passes.

In contrast, a roller compactor with spikes deploys an exclusive physical process to influence deeper soil layers. By focusing the whole enormous weight of the machine onto the tips of the metal spikes, these compactors produce a next level pressure compared to what a flat drum can do.

This feature is the reason behind any change in schedules, the saving of fuel and making sure the road bases and the foundations are very well prepared to be used for a long time. Let us just say that the pros and the recourse of such equipment have been discussed, and it is therefore understandable why such equipment is the preferred option for soil stabilization projects around the world.

The Science and Tech of Spiked Rolls

Extravagances in both physics and material science are what the making of a roller compactor with spikes represents. Contrary to a smooth drum that spreads the weight over a broad surface, a spiked drum concentrates that whole power to a limited number of tiny points. This feature has been very carefully thought out and done in such a way that the roller can face cohesive soils that are like a dense, rubbery mass when pressed.

With a smooth drum, the wet clay can be sealed only at the top while the soil underneath stays loose and full of air pockets. But a roller compactor with spikes actually breaks through that top layer.

Usually, the spikes are made of hardened steel, one of the high-strength, wear-resistant alloys, which means they can withstand soil and rock abrasions without their shape changed. Thanks to this strong structure, the machine can be used under the most extreme conditions without needing frequent repairs.

What goes on between the drum and the soil is indeed interesting ground. The drum’s movement helps to create the spike’s action during the soil penetration and extrusion, resulting in soil layers being sheared, mixed, and blended by spikes.

- Concentrated Pressure: Where the ‘foot’ of the spiked drum contacts the soil, a very high pressure can be exerted – much higher than can be achieved by a flat drum.

- Kneading Action: As the spikes enter and exit the soil they manipulate the soil layers, mixing and blending the material to ensure uniform moisture distribution and density.

- Durable Alloys: The spikes are made of hardened steel or similar wear-resistant materials so that they can penetrate hard, dry clays without breaking or wearing out quickly.

Outstanding soil particle penetration and binding

Among many other things, a Roller Compactor with Spikes can be described as a real game changer due to its deep soil penetration feature. Although smooth rollers can accomplish the final work like sealing asphalt or surface finishing of gravel, they can hardly bring about deep compaction in cohesive soils.

In such conditions, a smooth drum tends to bridge the low spots, thus leaving soft pockets that will eventually get potholes or cracks. In contrast, a Roller Compactor with Spikes goes through the lift being compacted and as such, the force of compaction is not only at the surface but also at the bottom of the layer. This is the kind of compaction that prevents delamination of soil layers – the most frequent cause of road failure – from happening.

Furthermore, these machines are excellent in soil aggregation. The soil clumps or lumps that are the biggest and troublesome to break are the very kind of soil from which an uneven and low-quality fill is made if such clods are buried intact.

The very aggressive nature of a Roller Compactor with Spikes allows it to destroy and pulverize soil clumps that are turned into earth particles to be packed close together. In this way, the void ratio (the volume of the empty space between pieces) is severely reduced so that the strength of the ground (the soil’s ability to bear the load) is greatly increased.

- Breaking Clumps: The extreme point pressure of the spikes makes grinding of big soil clods and clumps possible which would be just passed over by smooth rollers.

- Deep Compaction: The spikes penetrate the soil and compress it all the way from the bottom up to the top layer ensuring that there are no hidden weak layers.

- Void Reduction: The aggressive manipulation of the soil structure squeezes out trapped air and water, resulting in a denser, more stable soil matrix that is less prone to shifting.

Extra Grip and Use on Challenging Ground

Hardly will any construction site be flat, dry, and easy to work on. Operators are usually faced with a challenge of having to negotiate an area that is steep, muddy, and uneven which makes the use of standard equipment pointless.

That is why the Roller Compactor with Spikes is a major achievement when it comes to the appraisal of traction. The use of a smooth drum roller in a clay-heavy and wet spot might turn out to be a disaster as the roller can slide uncontrollably and fail to go up even small slopes.

Spiking on the drum can be compared to the cleat of a football shoe which allow penetrating into the ground, thus supplying the traction and enabling the roller to move forward and work effectively. Such grip is very important not only for productivity but also for the safety of the operator and the worksite.

This property is also extended to the different types of soil that these machines can handle. While they are undoubtedly the kings of cohesive soils such as clay and silt, they are also very efficient in soils of mixed nature.

Regardless of building a highway embankment, a dam core, or a landfill liner, the Roller Compactor with Spikes will guarantee with its reliable performance meeting the toughest engineering requirements. Thanks to their traction capability, the compaction will be uniform not only on the site but also on the edges and slopes that are most difficult to stabilize.

- Enhanced Grip: The spikes embed into slippery or wet surfaces, thus preventing the roller from sliding, and enabling it to be safely operated on gradients and slopes.

- All-Weather Operation: While smooth rollers may face challenges when working in wet conditions, spiked rollers can maintain their efficiency even when the soil is moist, thus ensuring that the project schedule is not affected.

- Terrain Adaptability: This type of machinery is highly versatile as it can easily navigate rough and uneven terrain while simultaneously leveling and compacting, thereby making the site ready for the next phase of the project.

Efficiency and Cost-Effectiveness

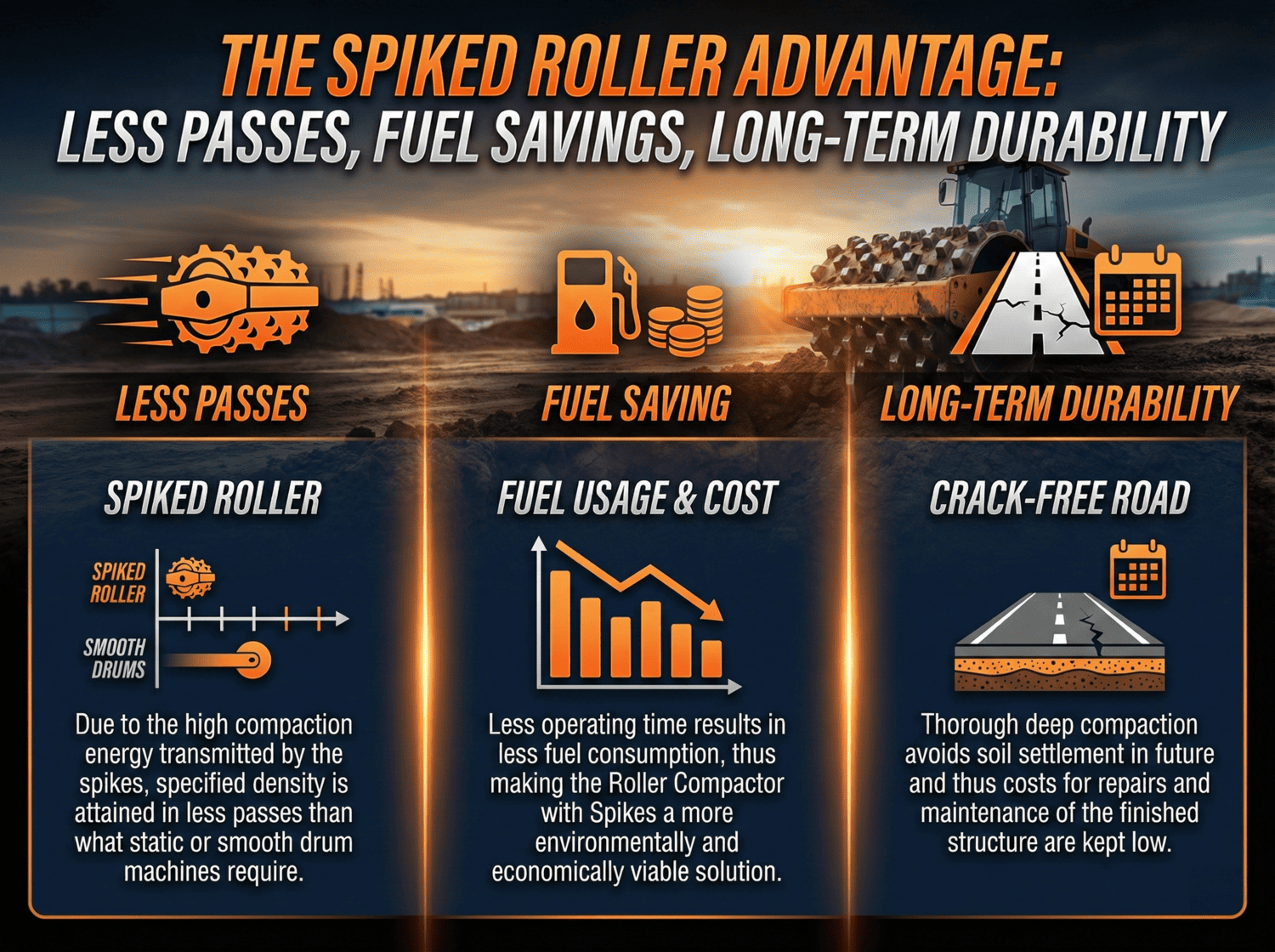

What drives the construction industry today is the strive for efficiency. Every hour of machine operation entails the use of fuel and the time of an operator. The Roller Compactor with Spikes remarkably improves the efficiency by cutting the number of passes needed to attain a certain density level.

Since the spikes issue a highly intense and focused energy into the soil, the desired soil compaction level can be achieved way earlier than in the case of conventional means. The cutting down on the number of passes translates directly to less fuel consumption and lower engine wear, thus reducing the overall costs associated with the operation of the machines.

Along with this, the cost-saving benefits of utilizing a Roller Compactor with Spikes in the long run are immense. Contractors, for instance, if they get a major compaction done properly, may save a lot of money by not having to deal with callbacks and repairs. Roads that are built on foundations with compactions made by spiked rollers do not suffer potholes, rutting, or the ground settling problems.

Such durability contributes to the good image of a construction company and hence provides the client with the greater value of his investment. The strength of the equipment that has been emphasized on websites such as rollercompactor.net makes it clear that the machines have been designed to withstand the test of time and thus represent excellent investments for the owners.

- Less Passes: Due to the high compaction energy transmitted by the spikes, specified density is attained in less passes than what static or smooth drum machines require.

- Fuel Saving: Less operating time results in less fuel consumption, thus making the Roller Compactor with Spikes a more environmentally and economically viable solution.

- Long-Term Durability: Thorough deep compaction avoids soil settlement in future and thus costs for repairs and maintenance of the finished structure are kept low.

Comparison: Spiked vs. Smooth Drum Rollers

In order to fully grasp the advantages of a Roller Compactor with Spikes for soil stabilization over the smooth drum version, a direct comparison of the properties of these two types will be a very useful first step. Both types of rollers, after all, have their function in the building industry but they serve different purposes.

| Feature | Roller Compactor with Spikes | Smooth Drum Roller |

| Primary Application | Cohesive soils (Clay, Silt) | Granular soils (Sand, Gravel), Asphalt |

| Compaction Method | Kneading and static/impact pressure | Static pressure and vibration |

| Penetration | Deep penetration (Bottom-up) | Surface compaction (Top-down) |

| Traction | Excellent on wet/slopes | Poor on wet/clay surfaces |

| Surface Finish | Rough, dimpled surface | Smooth, sealed surface |

| Moisture Control | Aiding in drying wet soil (increases surface area) | Seals moisture in |

- Target material: Spiked rollers are truly essential for clay and silt while smooth drum rollers are suitable for sand, gravel and finishing of asphalt.

- Compaction depth: Spiked rollers compact from the bottom to the top of the layer, thus ensuring the layer’s entire structural integrity; smooth rollers compact from the top to the bottom.

- Surface interaction: The surface left by spiked rollers is a textured one that adheres well to subsequent layers while the smooth rollers produce a slick one which if not scarified can cause the layers to separate.

Applications in Today’s Construction

The features of the Roller Compactor with Spikes have made it become the tool of choice in the execution of some very diverse construction works nowadays. One of the main uses, if not the most important is in highway engineering, and more specifically in sub-grade and sub-base preparation.

These are the layers that will bear the whole pavement weight and that of the traffic load as well. If the compaction is not done to a level that is near the maximum density of these layers, then the road will be a failure. Spiked rollers guarantee that these base layers are extremely solid.

Their usage in making earth dams and embankments is no less significant. Here, the integrity of the soil in terms of its watertightness and stability is a matter of public safety. The mechanical effect of the spikes leads to a homogenization of the soil by breaking down the soil particles and hence increasing its resistance to water permeability. Therefore, they are also the main stay of hydraulic structures.

Besides that, the setting up of large-size industrial premises and landfill works cannot do without these machines. It is a common knowledge that in a landfill the high density of waste and cover soil is the key to the proper use of space and the prevention of environmental contamination.

To gain the crushing force necessary for the compaction at the local scale and of the heavy clay liners used to contain them, the Roller Compactor with Spikes is the tool that local authorities and private entrepreneurs reach for. From a new subdivision of homes to huge public works, the ground preparation machines with such a feature continue to be the backbone supporting their success.

- Road Infrastructure: Indispensable for the compaction of sub-grades and bases so as to prevent their settling that would be the cause of pot-holes on highways and streets.

- Hydraulic Structures: A major contribution to the building of non-permeable earth dams, levees, and reservoirs by the elimination of the soil’s permeability.

- Landfill Management: In the preparation of the waste and clay liners for the best fit of the landfill, the densification and compaction of waste are practised to the maximum.

FAQs About Roller Compactors with Spikes

What is a roller compactor with spikes mainly used for?

A Roller Compactor with Spikes is mainly for the compaction of cohesive soils such as clay and silt. The spikes penetrate the surface and break up the clumps, thus removing the air voids and increasing the soil density layer by layer from the bottom up. The net result is a firm base for the structure.

What distinguishes a spiked roller from a sheepsfoot roller?

Nowadays, the two names are understood as the same machine. The theoretical difference between the two was the kind of protrusions; a sheepsfoot roller used to have cylindrical pegs, whereas today’s Roller Compactors with Spikes (aka padfoot rollers) have tapered pads or spikes. Thanks to the new design, mud is cleared more efficiently, and a more uniform compaction is realized as compared to the older, cylindrical type.

Is it okay to use a roller compactor with spikes on asphalt?

A roller compactor with spikes should never be used on asphalt. The spikes will tear up the smooth surface necessary for road paving. The use of such machines is restricted to soil and aggregate base densification. When it comes to asphalt, a smooth drum vibratory or pneumatic tire roller is what you need.

Why is the “kneading” effect so vital in soil compaction?

The kneading produced by the spikes is capable of rearranging soil particles so that they form a more compacted structure. This may be particularly important for cohesive (clay) soils requiring the permanent binding of soil particles and the expulsion of air. When these “sticky” soils are being compacted, static pressure alone usually does not suffice.

What is the maintenance required for a roller compactor with spikes?

Keeping check on the condition of the spikes for wear and breaking since worn spikes cannot perform as deep as new ones is the basic maintenance operation. Also, the drum scrapers (the bars that remove mud from between the spikes) have to be cleaned in order to avoid the accumulation of materials which would result in making the spiked drum a smooth drum thereby decreasing its effectiveness.

Are there vibratory features on roller compactors with spikes?

Indeed, most of the current Roller Compactors with Spikes are equipped with a vibration feature. Concentrating the heavy static weight, the penetrating spikes and the dynamic vibration, the compaction force is maximized, thereby enabling lift compaction in great depth and fast results.

What is the maximum depth a roller compactor with spikes can deliver compaction to?

Depending on the weight of the machine and the soil type, a Roller Compactor with Spikes can normally compact soil lifts (layers) effectively with a thickness from 6 inches up to 12 inches. This is a lot deeper than what lightweight plate compactors or smooth drums can do on cohesive soil.

Final Verdict on Why Roller Compactors with Spikes

Construction machines’ evolution is always about achieving better, faster, and more enduring results. A step in that direction is the Roller Compactor with Spikes. They have become the essential tools at building sites all over the world, delivering a cost-efficient, powerful and precise problem-solving means for cohesive soils, the main stumbling block towards successful infrastructure development in the past.

The western world is getting more and more dependent on the outstanding features of the Roller Compactor with Spikes as projects become more complex and deadlines, tighter. For soil stabilization contractors achieving excellence in their field will no longer be a matter of choice but a requirement if they decide to buy or rent this piece of machinery with the latest technology.