When to Use a Smooth Drum Roller

Importance of Choosing Perfect Equipment:

The process of choosing suitable equipment in the complicated area of soil compaction is still the most important thing for the whole project to be successful and have a long life. A smooth drum roller is one of the many beautifully designed and highly efficient and specialized instruments for compaction.

This vehicle is just simply made, but it performs a very important job of creating surfaces that are thick, strong, and even which usually is the basic factor for the quality of our modern infrastructure.

On the other hand, abuse caused by overuse will result in breaking the subbase supportive structure, cracking and breaking of asphalt, and the surface density will have been canceled; therefore, failure of the installation will be caused.

This ‘when to use a smooth drum roller‘ manual is the ultimate handbook that opens up the detailed specifics of the scenarios, materials, and the state of the project that a smooth drum is required, thus, providing these professional groups with information for making their decisions and getting the required results and work quality.

How to Recognize Smooth Drum Roller Characteristics?

Recognizing the smooth drum roller’s major characteristic is essential. Firstly, it employs its weight and vibration to dislodge soil particles or asphalt material, vacuuming air gaps and moisture, and thus obtaining the highest surface density.

When compacting material, the drum should be smooth and uninterrupted to provide uniform contact and pressure. It can unilaterally be a winner in some materials, but in others, it will be inefficient and harmful. I guess we should talk just a little about the ways this device can be used.

The Prime Application: Compacting Asphalt Pavement

A smooth drum roller generally depicts the most common and typical situation of just this, a mere gadget but an artist’s brush, finishing the surface to perfection, by applying it on a hot fresh asphalt layer.

The aim of asphalt compaction is to get a clean and straightforward asphalt surface which is a three times fold process: firstly the density is maximum to eradicate water infiltration and the formation of future potholes, secondly an even ride quality with the achieved smoothness is acquired for vehicles and lastly the durability of the surface is ensured by the sealing.

Achieving Optimal Density and Smoothness: The smooth drum roller is most often employed as either the intermediate or the finish roller in the asphalt compaction process.

- After the action of a breakdown roller (usually, a vibratory padfoot or a pneumatic roller for initial compression), the smooth drum’s large and flat surface works the asphalt mix, bringing the aggregate particles to the surface and at the same time making the viscous asphalt binder to fill in the newly formed voids.

- The result of this operation is a mat which is very dense, impermeable and smooth and very little deformation under the traffic loads are observed.

The Critical Temperature Window: In asphalt compaction, the less time the better and thus the smooth drum roller is only allowed to work in a certain compaction.

- One of the ways to achieve this is to operate the “window” with a hot mat that is still sufficiently pliable (usually between 220°F and 290°F).

- This is the moment that the mat is at the right temperature not to stick to the drum or shove under pressure yet not too hot to cause cracks or tears in the cooling surface.

- Thus, the operators must be extremely aware of the right temperature to do the job.

Preventing Surface Damage: Modern smooth drum rollers are equipped with the oscillating option that permits the drums to rotate in two directions.

- Thus, applying the shearing force which is very effective on slopes and prevents the mat from cracking or forming ripples—two phenomena that are at times encountered when the rolling is static.

- In such a way, they have become an absolute necessity to the highways’ crowns and curved parts.

Best Practices for Asphalt with a Smooth Drum Roller:

- Use a Water System: The water spray system of the drum must always be turned on in order to keep the metal surface from sticking to the hot asphalt which can create torn-up areas of the fresh mat and a low-quality finish.

- Over-Compaction Should be Avoided: Over-multiplying the passes, especially on already cooling asphalts, you will break the aggregate within the mix, thus the pavement will be weakened instead of being strengthened.

- A Rolling Pattern Should Be Used: The systematic, overlapping pass pattern allows you to distribute the density evenly over the entire width of the pavement and at the same time not leave any sections unmixed further.

Tackling Cohesive and Semi-Cohesive Soils

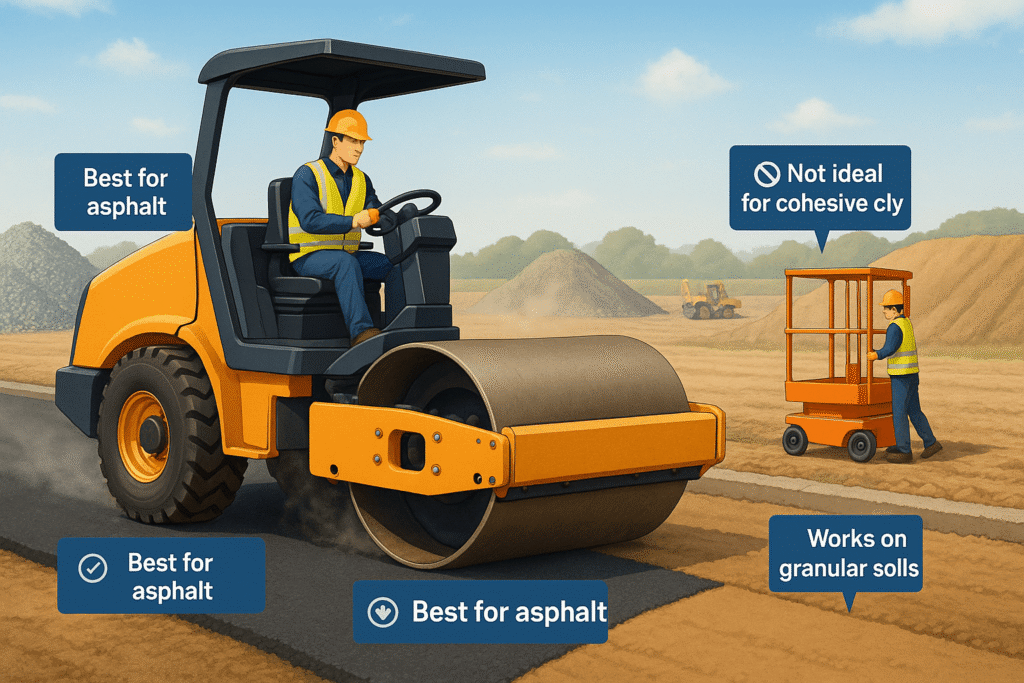

Even though the smooth drum roller cannot be as versatile with asphalt, it can still be one of the leading factors in soil compaction if it is applied on certain soil types. It only operates efficiently if the soil is of particular classification and has the right moisture content.

Perfect for Clay and Silt: The particles in the cohesive soil such as clay and in the semi-cohesive one like silt are so small that they attract one another on the molecular level. The wide, low-static pressure from the smooth drum roller is just the thing for these layers to be worked and compacted, at the same time to extend the surface area of the particles to one another, by greatly reducing the number of air voids.

The air voids are filled with particles of the same material thus a base is formed which is at the same time solid and non-permeable. This is the first step in the construction of stable subgrades for housing foundations, embankments, and pond liners where low permeability is the main requirement.

The Critical Role of Moisture Content: Water alone just is the key element in the whole process when soil particles are to be binded with each other tightly. The soil has to be very close to their optimum moisture content (OMC) in order to be compacted well. A dry soil, the air spaces will still be there and thus will be light and weak at the base, will not work properly and will still have air gaps.

In addition, when the soil is too wet it will also have a plastic consistency and if the drum is rolled on it will be compressed and at the same time it will be caused that the rutting, instability and finishing of the compaction process is led to fail.

Utilizing Vibration for Deeper Layers: One can say that the weight of the roller is the only reason for the job on the surface while the use of the vibratory function is the main cause for the achievement of the density in the deeper lifts.

Once the vibrations are transmitted the movement of the particles which are below the surface occurs and the layer is rearranged thus homogenous and solid. This layer can become a major contributor to the structural load of a building.

Best Practices for Soil with a Smooth Drum Roller:

Always Conduct a Proctor Test: Lab testing determines the Optimum Moisture Content and Maximum Dry Density of your soil, thus providing the target values for compaction in the field.

Execute Field Tests: Using a nuclear density meter or the sand cone test to check that the on-field procedure of compaction is maintained at the right standards throughout the process.

Work in Thin Lifts: The best way to handle soil is by cutting the layers that are too thick. The lift thickness of 18-24 inches for the vibratory smooth drum roller is normal that should be the first thing consulting the machine’s specifications and soil type for exact guidance.

The Versatility in Base and Subbase Materials: Crushed Rock and Gravel

For base courses such as crushed stone, gravel, and other granular materials, the smooth drum roller, particularly in vibratory mode, is a very effective tool. These materials are cohesionless, which means that their strength is derived from the mechanical interlock of the individual particles.

Creating Particle Interlock: The primary goal of compaction of gravel or crushed rock is to break and rearrange the angular particles in a way that they lock together tightly forming one rigid and stable layer. The vibratory smooth drum roller’s impulsive force is just right for such work. The vibrations fluidize the material, allowing particles to settle into their densest possible configuration under the static weight of the machine.

Providing a Stable Platform for Asphalt: A long-lasting asphalt pavement needs a well-compacted granular base as its foundation. The smooth drum roller guarantees that this foundation is impeccably even and densely packed. The slick surface is also helpful in making a grade-ready type of finish for the paving crew.

Superior Surface Finish: A smooth drum roller imparts a gravel base with a tight, closed, and relatively smooth surface, in contrast, to a padfoot roller that marks the surface with indentations. It is the case when the gravel is the final surface (e.g., rural roads, driveways, bicycle paths) or where a perfectly level subgrade is required for concrete pouring.

Best Practices for Granular Materials with a Smooth Drum Roller:

Vibration is Non-Negotiable: Compaction with vibration should always be the method of choice when using granular materials, such as gravel. The only static compaction, which is largely ineffective, is the method of choice for reaching the desired density in such mixtures.

Manage Moisture: Granular materials are less affected by moisture than clay. However, a small amount of water can make the compaction process much more efficient as it lowers the friction between particles, thus making them to move more freely (so-called “lubrication effect”).

Be cautious with soft stones: For instance, if you take sandstone or limestone aggregate and you will see that too much vibration may lead to the material’s breaking into smaller pieces and thus you change its gradation and reduce its shear strength.

When not to use a Smooth Drum Roller?

Just as it is important to understand the case for the usage of a smooth drum roller, knowing when to choose a different type is equally significant. Not only can time, fuel, and effort be wasted by improper material usage, but also the project can get damaged.

In static mode, a smooth drum roller is not only ineffective for loose, granular soils but it is highly inefficient on very loose, sandy soils in pure static mode. They might just sink or spin and there would be no/very few cohesive particles for the static pressure to have an impact on density. A vibratory roller should be used in such a case.

Rocky or Heterogeneous Fill: The partly large rocks in the fill that are mixed with soil the smooth drum will not help the situation and thus the pressure will cause the surface to be uneven. A padfoot or a heavy single-drum sheepsfoot is better if you want to break and then consolidate rocky fill.

Over-Compaction on Granular Surfaces: Over-vibration of certain well-graded granular materials can lead to over-compaction. In such a scenario, the aggregate may fracture, thus generating fines and changing the material properties, which may result in the reduction of stability.

Smooth Drum vs. Padfoot vs. Pneumatic: A Quick Comparison

| Feature | Smooth Drum Roller | Padfoot Roller | Pneumatic (Rubber-Tired) Roller |

|---|---|---|---|

| Primary Use | Finishing asphalt, compacting cohesive soils & granular bases | Compacting cohesive soils in deep lifts | Compacting asphalt (intermediate/finish), sealing surfaces, proof-rolling |

| Best For | Creating smooth, sealed surfaces; kneading fine-grained soils | Breaking down clay and silt in thick layers; trench work | Kneading action on asphalt; blending aggregate layers; providing a tight seal |

| Surface Finish | Very smooth | Rough, indented | Smooth, sealed |

| Soil Type | Clay, Silt, Gravel (with vibration) | Clay, Silt | Sandy soils, gravel, asphalt surface course |

| Key Advantage | Superior finish on asphalt and granular surfaces | Deep compaction and kneading of cohesive soils | Kneading action; avoids fracturing aggregate; excellent for proofing |

Conclusion: Choosing the Right Tool for the Job

The smooth drum roller is at its best compaction technology, but it is not a general system of use. Its value goes from one hand to another through precise application. If you want to clean and densify the surface of an asphalt road, this is the only machine you can use.

It is very good if the goal is to work the clay soils and wet them at their optimal moisture content turning them into a solid and water-resistant base. Its vibratory features are essential if one desires to fix materials of granular bases in a stable and interlocked matrix.

The skilled driver or as a project manager, may be implied, is aware that practical tests, material requisites, and project objectives must be the main indicators for equipment selection. No matter how much you stick to the compaction science and the special role of the smooth drum roller, it is the quality that will be there not only at the specification level but also as a part of the longevity of the project.

Still, if it happens that your next project is paved with asphalt, clay, and silt along with gravel, then why wouldn’t you go for the smooth drum roller? The densification tool that allows a perfect finish of the surface is just the right one for the job.

Frequently Asked Questions (FAQs)

Can a smooth drum roller be used on gravel roads?

Yes, definitely. A vibratory smooth drum roller is an ideal tool for compacting and maintaining gravel roads. The vibration helps to lock the gravel particles tightly together, thus making the surface denser, more stable, and with a longer lifespan. In addition, this smoother final finish compared to a padfoot roller is also part of the advantages of using a smooth drum roller.

What is the difference between static and vibratory mode on a smooth drum roller?

Static compaction is reliant only on the dead weight of the machine where the pressure is applied to the ground or surface by the weight. So in this case, the roller is suitable for asphalt that is less than an inch of finish and soil lifts of such a thickness. Vibratory compaction utilizes high frequency, low amplitude shaking force generated by an internal eccentric shaft. The energy of the shaking penetrates the source deeply, hence fastening the compaction efficiency to a large extent. Consequently, the densification of soils and base materials can be done in depth.

What is the typical lift thickness for a smooth drum roller?

For setting up a proper lift thickness, the material and the use of vibration are the main factors. If the soil is properly compacted by vibration, the lifts would be typically 18 to 24 inches thick. Lift thickness in asphalt is controlled by the paving machine, and as a rule, a single layer of no more than 4 inches is laid. The operator manual of the roller should always be the first reference for the particular unit in terms of weight and vibration amplitude to be able to know the specific capabilities.

How do I prevent asphalt from sticking to the drum?

This problem pops up quite often but the prevention is very simple, i.e. the roller’s water spray system which is always there. The water spray system is the actual supplier of water to the drum surface in a thin layer which is the barrier between the hot asphalt and the metal drum. The requirement that the water tank be full and the spray bars are not clogged should be met before the start of the compaction process.

Can I use a smooth drum roller on a slope?

Sure but you need to be cautious. A standard rolling scenario down and up a slope is that the drum will be exerting a pushing force on the downhill material. It is thus advisable to roll along the slope (on the contour lines) rather than rolling up and down for slopes. Furthermore, numerous modern smooth drum rollers are equipped with the oscillation feature that is very successful for operation on slopes as it helps in the material push and consequently the risk of Cracking is less.

Is a smooth drum or padfoot roller better for clay?

At the beginning of the procedure to be able to break the clay in its thickest layers, a padfoot roller is the most suitable. The pressure points of the padfoot roller break the clumps and smartly knead the lower soil. Still, the first few passes are mainly done with the aid of a smooth drum roller for sealing the surface and to form a smooth grade. In this way the layer is sealed, and water is unable to go into the indentations formed by the smooth drum roller and hence the layer is protected from the padfoot.

What are the Safety Precautions When Operating a Smooth Drum Roller?

Some steps that can be taken for safety include: always doing the pre-operation walk-around inspection without fail; always wearing the seatbelt and using the Roll-Over Protective Structure (ROPS); being very vigilant of your surroundings in particular if you are close to the edges or other workers on foot; making sure that there is proper communication with a spotter and that you never leave the machine if so, without supervision.