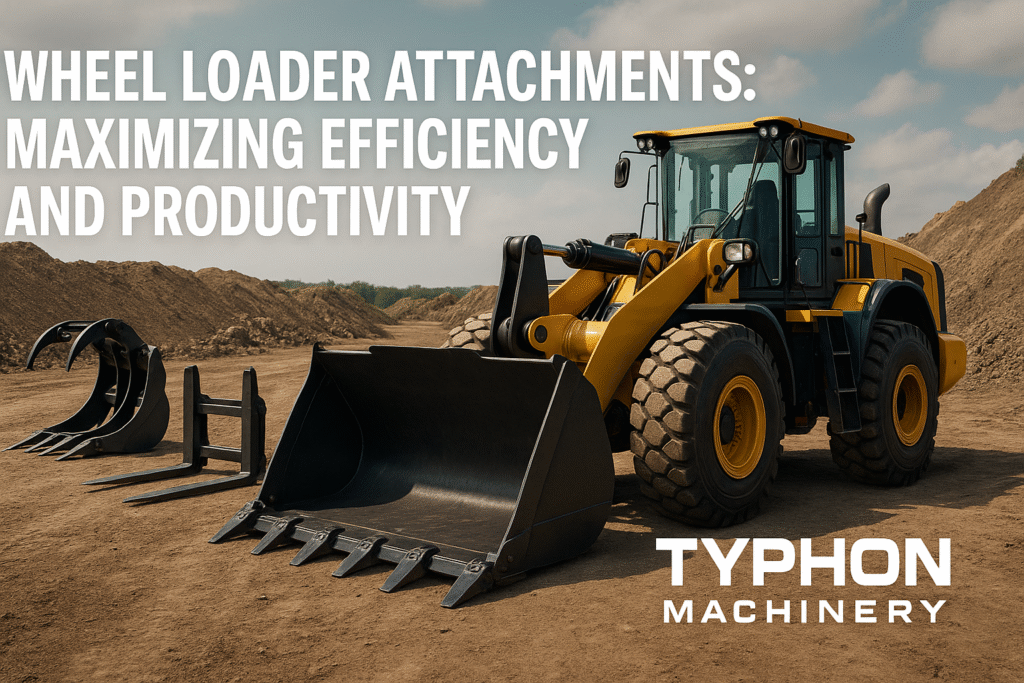

Wheel loaders have been in the market for the longest time, which has seen them been used in various sectors such as construction, mining, agriculture, and material handling. Use of the machines has been boosted by improvements in power, and mobility features that are superior, with versatility as one of the leading factors.

Additionally, we will quickly highlight the fact that attachments are the most important factors because they are the means of carrying out work by hand.

Importance of Wheel Loader Attachments

Attachments will then be specified as the accessories in the form of tools that are fixed on a standard wheel loader making it multifunctional and thus efficiency and productivity being on a very high level in the work sites.

If your job is concerned with heavy machine sales or you are a construction fleet operator, the understanding of the wear loader attachments is truly a game change. This following guide will hence tell all about the regular attachments that are in use, areas they are used for, the benefits as well as ways of choosing the best that fits your work properly.

Why Attachments Are Game Changers for Wheel Loaders

Indeed, the wheel loaders attachments are just the perfect tools that can turn a powered wheel loader really into a multi-role beast as with one machine any work is possible. In lieu of buying a lot of machines, companies can use one skid steer loader with various gear for a wide range of tasks. Here are the reasons why:

- Reduced Equipment Costs: Each work application does not require the procurement of an item from the supplier because a number of them can be carried out by an individual.

- Improved Machine Utilization: Get the highest revenues back when you use most of the equipment across different functions.

- Operational Flexibility: you can stop one job and begin the other one in an instance such as moving materials with a wheel loader to grading an area.

These benefits are particularly essential for sectors where everyday life is effected by the availability of limited time, space, and money.

Top Loader Wheel Attachments & Their Functions

What about if we look at the best wheel loader attachments that are working great for your productivity and efficiency?

1. General Purpose Bucket

This is the most conventional and basic wheel loader attachment that is suitable for shifting loose material such as sand, gravel, and dirt.

- High Volume Capacity: Created to get filled up to the top in the shortest time so as to make fewer trips.

- Durable Construction: Built of robust steel, thus minimizing wear.

- Ideal Applications: Excavating, truck loading, and piling operations.

| Feature | Description |

| Typical Width | 6 to 10 feet |

| Bucket Capacity | 1.5 to 5 cubic yards |

| Best for | General construction, landscaping, mining |

2. 4-in-1 Bucket

A 4-in-1 bucket can contribute in a variety of ways, like a bulldozer, loader bucket, clam grapple, and scraper.

- Multi-functional: It is good for pushing, pulling, drilling, and smooth road surface.

- Increased Versatility: The usage is so wide that, if several small machines cannot be hired, this one bucket alone is enough.

- Improved Efficiency: It can minimize the number of times the accessories need to be replaced, hence, the time lost is also reduced.

3. Pallet Forks

Do you know that with the help of pallet forks, you can convert your loader into a kind of lift truck for palletized goods?

- Enhanced Lifting Capability: They are a perfect fit for materials that are being used in construction works i.e. the bricks and cement bags.

- Adjustable Tines: These can be easily modified to suit different load dimensions.

- Great for Warehousing: This is a common type of forklift used in timber mills, general depots, and distribution centers.

4. Grapple Bucket

Light and great for waste collection, the Grapple bucket is the most suitable tool to use when you need to work with irregular or bulky loads such as, logs, scrap, or loose materials.

- Hydraulically Operated Clamps: They are practical for uneven and other types of loads as well.

- Perfect for Forestry & Waste Management: This kind of debris handling machine is pretty much as if a forest is being cleared from the debris caused by the storm. It also includes logging industries and similar places.

- Minimizes Spillage: It makes sure the material transferring is safer as well as more resource-effective.

5. Snow Blowers & Snow Pushers

Devices mainly created to deal with the snow in colder areas of the world, snow blowers & snow pushers further confirm the attachment’s usability and unmatched speed of taking on the cold fury.

- Hydro Rotation and Deflection: With these attachments, users can change the snow’s output direction using the switch which flows it to the required

- Must-Have for Municipal Work: Often used in airports, parking lots, and city streets.

Industry-Specific Uses of Wheel Loader Attachments

As with other industries, so with construction, mining and any other sector, different tasks demand different high-efficiency tools. Selecting the right attachments will not only increase productivity but also reduce the operating costs as well. Below are the details:

Construction

- Buckets for Earthmoving

- Hydraulic Breakers for Demolition

- Forks for Material Transport

Agriculture

- Bale Spears for Hay Handling

- Manure Forks

- Silage Grabs

Mining & Quarrying

- Rock Buckets for Heavy Material

- Scale Attachments for Weighing

- Dust Control Units

Forestry

- Grapples for Timber Handling

- Stump Grinders

- Winches

Key Benefits of Using Wheel Loader Attachments

Wheel loader Attachments of wheel loaders means not only comfort, but it also delivers real-life benefits which are directly reflected in your financial statements.

- Reduced Operational Costs

- A single machine can play several roles at the job site.

- The expenditure of the maintenance and fuels can be reduced for each task.

- The workforce can be cut at the jobsite.

- Higher Jobsite Productivity

- There is less time involved in changing machines.

- The on-time status of the machine is raised.

- Work can be finished within tighter deadlines.

- Enhanced Safety and Precision

- Devices like laser-guided graders or scale systems can help minimize mistakes.

- Automated couplers eliminate manual pin changing.

- More accurate load control can be achieved by using specialized forks and clamps.

Choosing the Right Attachment for the Job

Not every attachment fits every loader or job. Here’s what to consider:

| Criteria | What to Look For |

| Machine Compatibility | Ensure hydraulic and mounting system match your loader |

| Material Type | Use heavy-duty buckets for rocks; light-duty for soil |

| Job Frequency | Invest in high-cost attachments only for regular use |

| Operating Environment | Snow, mud, urban or rugged terrain all impact choice |

| Budget vs ROI | Estimate long-term value over upfront cost |

Maintenance Tips for Wheel Loader Attachments

The good condition of your attachments is an assurance of the long service life and the high-quality work with them.

- Regular Inspection:

- Check for wear on bucket edges and teeth.

- Inspect hydraulic lines for leaks or cracks.

- Examine welds and couplers.

- Lubrication & Greasing

- Adhere to the lubrication schedules stipulated by the equipment manufacturer.

- Focus on the pivot points and the hydraulic systems.

- Grease the moving parts after pressure washing.

- Storage Best Practices

- Keep in a covered and dry place.

- Raise from the ground to prevent rusting.

- Use 0plastic caps to protect the hydraulic couplers when storing the unit.

Smart Couplers: Speed Meets Safety

A variety of current attachments are equipped with smart coupler units ensuring that the time for changing equipment is drastically reduced.

Advantages of Hydraulic Couplers:

- No Hands: The pin is not required to be involved in the manual process.

- Save Time: Swap attachments in under sixty seconds.

- Enhance Safety: Fewer operator injuries.

Moreover, many of the equipment manufacturers provide smart coupler systems, which are wired to vehicles and are able to confirm that attachments are correctly installed via dashboard notifications.

Attachment Trends to Watch in 2025

Technology is now enabling a new breed of attachments for wheel loaders. The innovative trends:

- Electrically Operated Attachments: Precision is further guaranteed with electric control over hydraulic movement.

- Telematics Integration: Information on attachment performance is readily available in real time.

- Eco-Friendly Designs: Attachments planned and created with minimum energy consumption in mind are termed as eco-friendly designs.

- Autonomous Attachment Recognition: Devices that can recognize the tool connected and configure themselves are known as autonomous attachment recognition systems.

Conclusion: Uplifting Productivity One Implementation at a Time

Wheel loader accessories are not just ordinary extraneous add-ons rather they are strategic assets that enable better productivity, deliver cost savings, and enhance flexibility in various work situations.

An in-depth understanding of the equipment your operations require and wise compatibility of those wheel loader attachments can transform a clumsy, lengthy process into a nimble, cost-effective, and multitasking operation team.

In various fields such as construction, farming, or extracting minerals, being informed of your choice of attachments and keeping them in good condition guarantees the most uptime, safety, and profit.

Frequently Asked Questions about Wheel Loader Attachments

- What attachment should I use for moving large rocks?

If you want to move large rocks, the best choice is between rock bucket and heavy-duty grapple attachments. These attachments are super hard and the outer layer is treated with a strong material to prevent crack and reduce wear caused by adverse weather conditions.

- Can I use the same attachment on different wheel loaders?

There are a few factors that decide if the attachment can be shared or not. You always need to verify the hydraulic settings as well as the coupler design of another machine. Going with the universal couplers will provide more options, but not all the brands align with the standards.

- How frequently should I inspect my attachments?

A visual and monthly in-depth inspection regularly. When working in areas with a high volume of tasks, pressurized hydraulic checks may be necessary even up to once a week.

- Are quick couplers safe?

Yes, modern quick couplers are equipped with the features of locking indicators and fail-safes. They are of great help in securing and expediting the process only after conforming to the specifications required.

- Can I rent attachments instead of buying them?

Absolutely, dealerships with many pieces of machinery also offer renting equipment. It is an economically viable strategy for small or one-time tasks.

- What is the right attachment for snow removal?

The best selection would be a snow blower for heavy snowfall and a snow pusher for light to medium snow. When it comes to choosing the attachments, the snowfall amount and the surface area should be your principal factors.

- Do the fuel efficiency of a loader and attachments coincide?

It is true that bulky attachments or items that have a high level of resistance may lead to fuel consumption by the loader. However, to keep the fuel efficiency of the machine, the proper attachment for the right work is strongly recommended.