The Magic Behind Sheepsfoot Rollers in Road Construction

When it comes to the marvels of modern construction, few pieces of equipment are as essential and specialized as the sheepsfoot roller. This article dives deep into the world of sheepsfoot rollers, uncovering their purpose, mechanics, and indispensable role in road maintenance.

Understanding the Sheepsfoot Roller

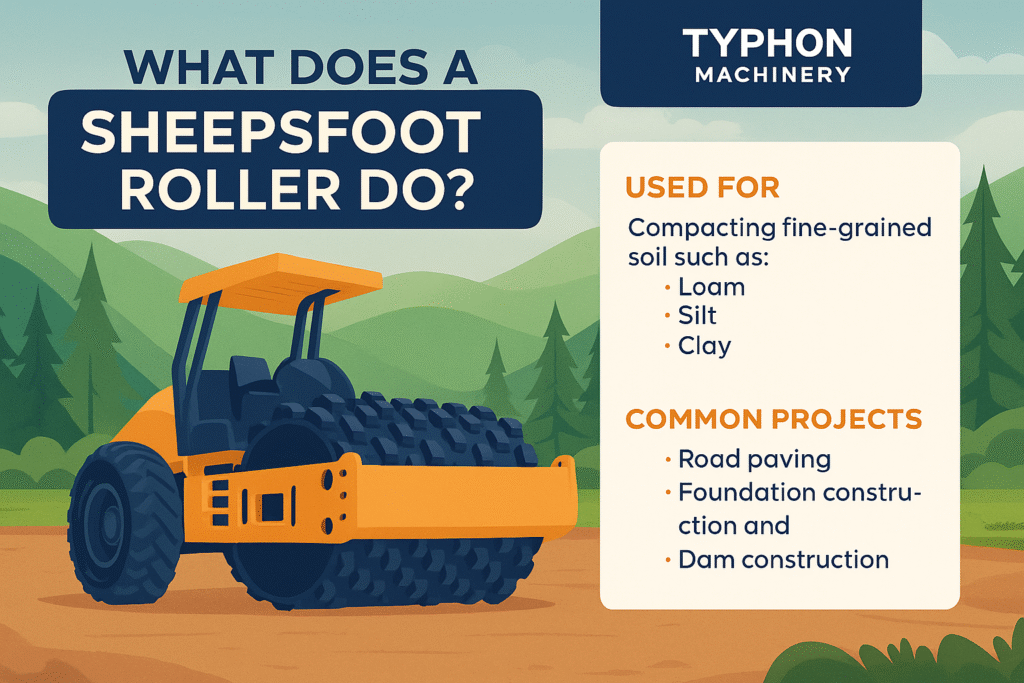

The sheepsfoot roller is a distinct type of compaction equipment widely used in the construction industry, primarily for road construction and soil compaction. Unlike other rollers, the sheepsfoot roller boasts a unique design with rectangular-shaped protrusions, or “feet,” which make it particularly effective at compacting cohesive soils like clay. This results in a denser, more stable foundation ideal for roadways and other construction projects.

For construction professionals, civil engineers, and road maintenance workers, understanding the sheepsfoot roller’s function and benefits is crucial. It offers superior compaction by imparting high pressure over a small area, effectively crushing and kneading the soil. This process reduces air pockets and increases soil density, providing a stable base for subsequent layers of construction.

In the following sections, we’ll explore how a sheepsfoot roller works, the different types available, its critical role in road construction, best practices for usage, and even a glimpse into future advancements.

How Does a Sheepsfoot Roller Work?

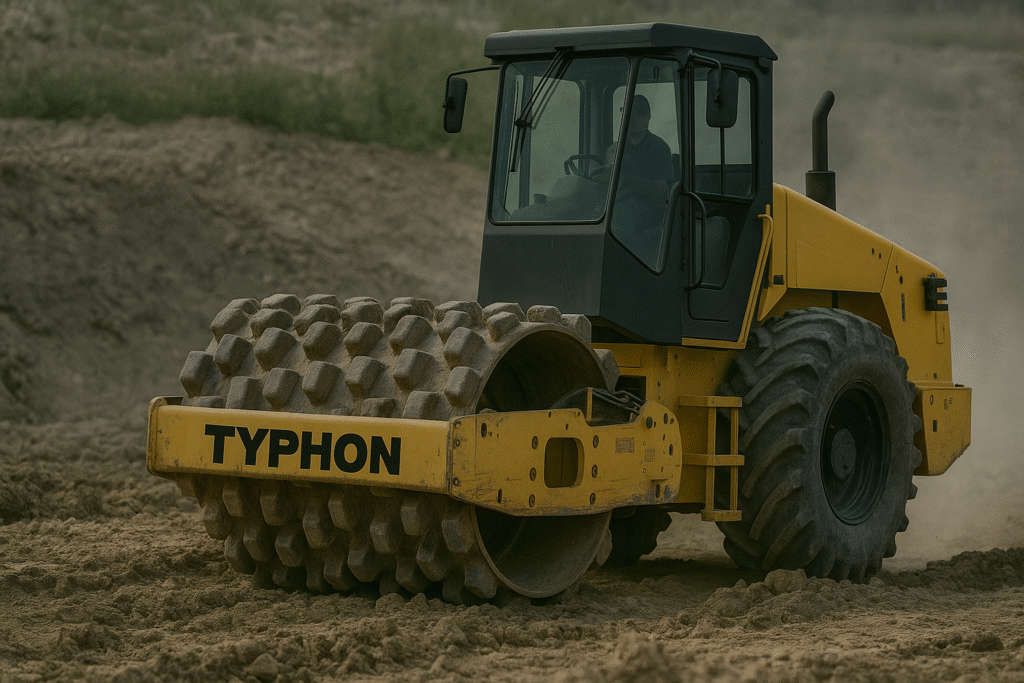

The design and functionality of a sheepsfoot roller set it apart from other compaction tools. At its core, the roller consists of a cylindrical drum fitted with numerous rectangular feet that project from its surface. These feet penetrate the soil, compacting it from the bottom up, which enhances the overall density and stability of the material being compacted.

When the sheepfoot roller is in operation, the weight of the drum, combined with the protruding feet, exerts significant pressure on the soil. This pressure crushes soil lumps and removes air pockets, leading to a tightly compacted layer. This unique design allows the roller to achieve higher density levels than flat or smooth rollers, making it especially effective for cohesive soils such as clay or silt.

The process involves multiple passes over the same area, gradually building up the compaction level with each pass. The initial passes aim to break down larger lumps and aerate the soil, while subsequent passes focus on achieving the desired density and stability. This method ensures thorough compaction, which is essential for the longevity and durability of road surfaces.

Types of Sheepsfoot Rollers

Sheepsfoot rollers come in various types, each designed for specific applications and compaction requirements. Understanding these types helps construction professionals choose the right equipment for their projects.

Towed Sheepsfoot Rollers

Towed sheepsfoot rollers are attached to a tractor or other heavy machinery and pulled across the construction site. These rollers are typically lighter and more maneuverable, making them ideal for smaller projects or areas with limited access. Their ease of use and versatility make them a popular choice for many construction projects.

Self-Propelled Sheepsfoot Rollers

Self-propelled sheepsfoot rollers, as the name suggests, have their own engine and can move independently. These rollers are generally heavier and more powerful, suitable for large-scale projects requiring extensive compaction. Their increased weight and pressure capabilities make them highly effective for compacting thick layers of soil.

Static vs. Vibratory Sheepsfoot Rollers

Sheepsfoot rollers can also be classified based on their compaction mechanism. Static sheepsfoot rollers rely solely on the weight of the drum and feet for compaction, while vibratory sheepsfoot rollers incorporate a vibrating mechanism to enhance compaction efficiency. The vibration helps the feet penetrate deeper into the soil, achieving higher density levels with fewer passes.

By understanding the different types of sheepsfoot rollers, construction professionals can select the most appropriate equipment for their specific needs, ensuring optimal compaction and project success.

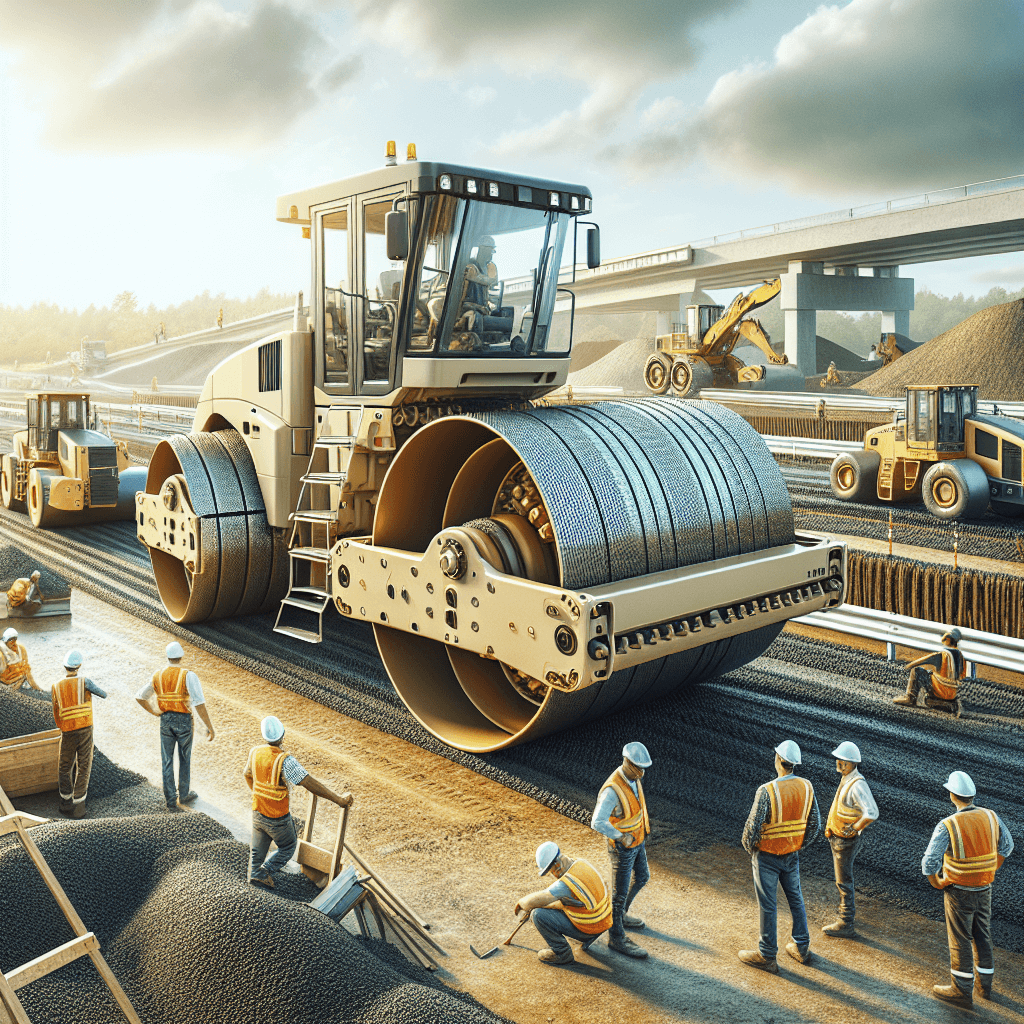

The Role of Sheepsfoot Rollers in Road Construction

Sheepsfoot rollers play a crucial role in road construction, contributing to the stability and durability of road surfaces. Their primary function is to compact the subgrade and base layers, providing a solid foundation for the road.

The subgrade layer is the bottommost layer of the road, consisting of native soil or compacted fill material. Compaction of the subgrade is essential to prevent settlement and ensure a stable base for the road. Sheepsfoot rollers are highly effective at compacting cohesive soils, making them ideal for this task. By reducing air pockets and increasing soil density, they create a solid foundation that can withstand the loads and stresses of traffic.

Once the subgrade is adequately compacted, the sheepsfoot roller can be used to compact the base layer. The base layer typically consists of crushed stone or gravel and provides additional support and drainage for the road. Proper compaction of the base layer ensures that it remains stable and prevents the formation of ruts and potholes.

In addition to subgrade and base layer compaction, sheepsfoot rollers are also used for compacting materials such as asphalt and concrete. Their ability to achieve high-density compaction makes them invaluable for creating durable and long-lasting road surfaces.

Best Practices for Using Sheepsfoot Rollers

To maximize the efficiency and safety of sheepsfoot rollers, it’s essential to follow best practices for their operation and maintenance. Here are some practical tips for construction professionals:

Pre-Operation Inspection

Before using a sheepsfoot roller, conduct a thorough inspection to ensure all components are in good working condition. Check the drum, feet, engine, and hydraulic system for any signs of wear or damage. Address any issues before starting the compaction process to prevent breakdowns and ensure optimal performance.

Proper Operation Technique

When operating a sheepsfoot roller, maintain a consistent speed and avoid sudden starts or stops. Gradual acceleration and deceleration prevent soil displacement and ensure even compaction. Additionally, use overlapping passes to cover the entire area and achieve uniform compaction.

Regular Maintenance

Regular maintenance is crucial for keeping sheepsfoot rollers in top condition. Perform routine checks on the engine, hydraulic system, and drum components. Lubricate moving parts and replace worn-out feet to maintain compaction efficiency. Adhering to a maintenance schedule minimizes downtime and extends the lifespan of the equipment.

By following these best practices, construction professionals can optimize the performance of sheepsfoot rollers, ensuring efficient and safe compaction operations.

The Future of Sheepsfoot Rollers

The construction industry is continually evolving, and so is the technology behind sheepsfoot rollers. Advancements in design and functionality are making these rollers even more effective and efficient.

One notable innovation is the integration of GPS and sensor technology into sheepsfoot rollers. These systems provide real-time data on compaction levels, allowing operators to monitor and adjust their techniques for optimal results. GPS-guided rollers ensure precise coverage and eliminate the risk of over or under-compaction.

Another exciting development is the use of autonomous sheepsfoot rollers. These self-driving machines can perform compaction tasks without human intervention, increasing productivity and reducing labor costs. Autonomous rollers are equipped with advanced sensors and AI algorithms to navigate construction sites and perform accurate compaction.

Furthermore, advancements in materials and manufacturing techniques are improving the durability and performance of sheepsfoot rollers. New materials with enhanced wear resistance and strength are being used to construct the drum and feet, ensuring longer service life and reduced maintenance requirements.

Sheepsfoot Rollers vs. Other Rollers

In the realm of construction, selecting the right type of roller is crucial for achieving optimal compaction. While sheepsfoot rollers are renowned for their effectiveness in compacting cohesive soils, there are several other types of rollers each suited to specific applications.

Smooth Drum Rollers

Smooth drum rollers, or static rollers, are ideal for compacting granular soils like sand and gravel. Unlike sheepsfoot rollers, smooth drum rollers exert even pressure across the soil surface, making them less effective in breaking up clay or silty layers but excellent for leveling and finishing granular materials. Their cylindrical drum ensures smooth finish passes, which is necessary for road surfacing.

Pneumatic Rollers

Pneumatic rollers, also known as rubber-tired rollers, use a series of rubber tires that provide kneading action, making them versatile for a variety of soil types, including granular and asphalt materials. These rollers are known for sealing the surface layers and providing a smooth finish, which sheepsfoot rollers, with their protruding feet, cannot achieve. The flexibility of tire pressure allows for different compaction outcomes, offering additional control.

Vibratory Rollers

Vibratory rollers amplify the basic static compaction by employing vibrations to break up soil particles. This type of roller is efficient on materials that require higher energy to achieve desired density, similar to vibratory sheepsfoot rollers, but often used in applications where deep compaction is necessary across homogeneous soil types. Their ability to handle a wide range of soil textures makes them a preferred choice for various construction scenarios.

Grid Rollers

Grid rollers consist of a steel grid drum that can crush and compact robust, rocky materials, making them especially useful in applications that involve road building over hard surfaces. The grid pattern provides an advantage in breaking down surface rocks compared to the sheepsfoot roller, which excels in cohesive soil environments.

By understanding the strengths and applications of different roller types, construction professionals can make informed decisions on the best equipment to use, ensuring efficient, effective, and lasting compaction results tailored to specific project requirements.

Summing Up the Sheepsfoot Roller’s Importance

In conclusion, the sheepsfoot roller is an indispensable tool in the construction industry, particularly for road construction and soil compaction. Its unique design and functionality make it highly effective at achieving high-density compaction, ensuring stable and durable foundations.

By understanding how a sheepsfoot roller works, the different types available, and best practices for its use, construction professionals can maximize its benefits and achieve optimal results. Looking ahead, technological advancements promise to further enhance the efficiency and effectiveness of sheepsfoot rollers, making them an even more valuable asset in the construction industry.

For those interested in learning more about sheepsfoot rollers and their applications, we recommend exploring the following resources and references. And if you’re looking to integrate advanced compaction equipment into your projects, consider signing up for updates from our industry-leading experts.

By staying informed and utilizing the latest advancements in construction equipment, professionals can ensure the success and longevity of their projects, ultimately contributing to safer and more reliable infrastructure.