Vibratory Tamper: The Compact Power Tools Every Road Crew Needs

When it comes to infrastructure development, especially road construction, there’s a must-have of precision, speed, and reliability. As far as stability and strength of our roadways’ base is concerned, road crews’ heavy machineries vary from massive double-drum rollers to asphalt pavers. However, among these larger machines, there is a smaller, essential tool, the vibratory tamper.

Left out from being the main focus because of the huge heavy machinery with which they share the job, a vibratory tamper is actually the key to successful compaction in those places that are inaccessible for heavy equipment. For any road crew who is serious about durability and structural safety in their projects, it is a must, rather than a choice, to know the operations, uses, and the great advantages of a vibratory tamper.

These machines are designed to produce a high-impact force within the limited space of the work area, so compacting trench backfills, paving to the edges, that is any small, confined area, ensuring that the soil density is optimal to withstand heavy traffic loads and environmental abrasion.

The Mechanics Behind the Power: How Vibratory Tamper Works

One cannot give a comprehensive explanation about the importance of a vibratory tamper without mentioning the fundamental engineering aspects on which it is based. In contrast to static rollers which depend on their weight to press the ground, a vibratory tamper delivers high-frequency percussive blows to the soil surface.

This is usually a gasoline- or diesel-engine-powered device which operates a piston system, converting the rotational energy into a very fast upward/downward motion. This motion thus exerts an increasing force on the particles in the soil, making them tightly packed while the air voids that cause settling or structural failure later on are trapped out.

- High-Velocity Impact: The tamper’s foot makes quick successive catches on the ground surface at a high frequency, generally between 500 and 750 blows per minute, which is the main purpose for soil particles to be re-arranged tightly together.

- Cohesive Soil Specialization: The strong impact makes good results on cohesive soils such as clay and silt where the particles are held tightly therefore a very high amplitude force is necessary to break the particles and expel the air pocket.

- Spring-Loaded System: The advanced tampers nowadays have the spring-loaded system integrated within their leg that not only increases the impact force but the shock is also partly absorbed.

Why Every Road Crew Needs a Vibratory Tamper in Their Fleet

Vibratory tamper is absolutely a must-have tool when the road crews have to face the fact that big compaction machines just cannot do it all. Ride-on rollers might be a very efficient means of compacting long stretches of highways but they are of no use whatsoever in very narrow utility trenches or being around the fragile manhole corners.

A vibratory tamper is a perfect hybrid, a hand tool with an inch to inch compaction power of a large compactor.

Sadly, if such small spaces are left unhandled, the problem of “bridging” happens, and the top layer gets very hard whereas underneath the soil remains loose, ultimately potholes and pavement collapse.

- Confined Space Mastery: These downsized tools, and a narrow foot which is a part of their design, are thus capable of getting easily into trenches, ditches and foundations, where the space is limited to less than 24 inches.

- Precision Compaction: No one can argue the fact that some operators are, even with the help of these machines, better in getting soil compacted right up to the edges of the walls, pipes, and any other structures which the children of the wide plate compactor might damage quite easily.

- Versatility in Application: They also come very handy for compacting soil backfill along the pipelines, cable trenches, and drainage systems to ensure that even the underground infrastructure is as good and as strong as the top surface.

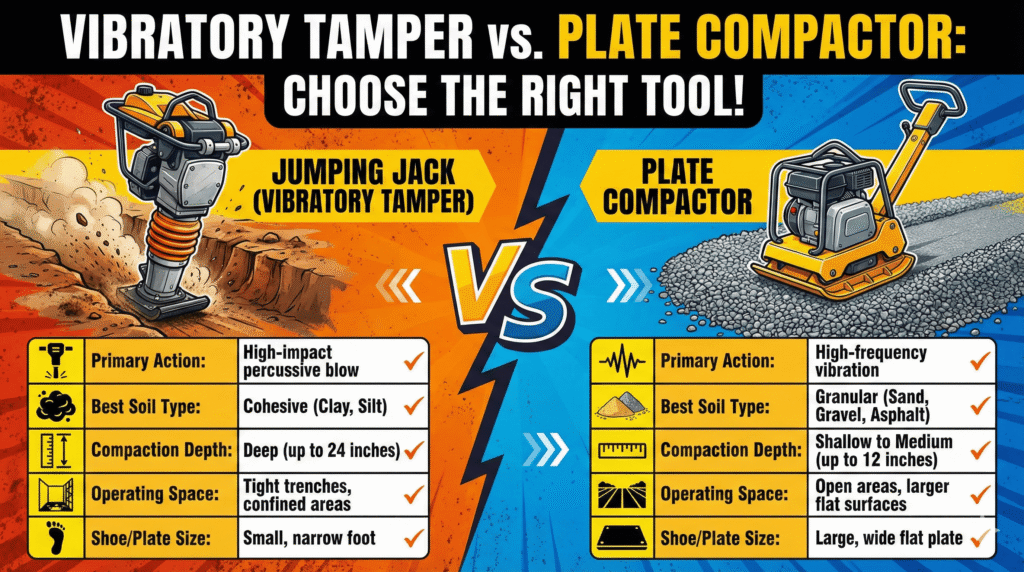

Vibratory Tamper vs. Plate Compactor: Understanding the Distinction

Those new to the work in the industry tend to mix up vibratory tamper (also called jumping jack) and plate compactor. In reality, although they are collectively termed soil compaction equipment, the two different pieces of equipment mainly differ in the type of soil they are suitable for and the kind of job each is designed to perform. So, a plate compactor applies vibration to sand and gravel, which are granular soils, hence making the particles move downwards.

Conversely, a vibratory tamper applies an impact force to knead and compress the clay type of soil. The result when one uses the wrong equipment is either poor compaction density or even machine damage.

| Feature | Vibratory Tamper (Jumping Jack) | Plate Compactor |

| Primary Action | High-impact percussive blow | High-frequency vibration |

| Best Soil Type | Cohesive (Clay, Silt) | Granular (Sand, Gravel, Asphalt) |

| Compaction Depth | Deep (up to 24 inches) | Shallow to Medium (up to 12 inches) |

| Operating Space | Tight trenches, confined areas | Open areas, larger flat surfaces |

| Shoe/Plate Size | Small, narrow foot | Large, wide flat plate |

- Force Delivery: Compared to those of the plate compactor whose principle is low-amplitude vibration, the stroke amplitude of the vibratory tamper is very high, and the mode of action can be simplified as punching the soil.

- Handling Differences: Tamper operators should expect that their body weight will fluctuate more pronouncedly in their machine as it ‘jumps’ thus more physical effort is needed, whereas a plate compactor moves by gliding on the surface with the force of forward momentum.

- Moisture Content: Clay-rich soils, which are normally the most challenging to compact, are easier to handle for tampers as compared to plate compactors that tend to get stuck or sink if granular material is too wet.

Operational Safety and Ergonomics for Road Crews

Using a vibratory tamper is no child’s play, and therefore a proper skilled operator is a must as well as following a set of stringent safety guidelines at all times. The first and foremost aspect of the operation that contains the risk is- the nature of the machine which quite literally ‘jumps’ for the best output.

However, there have been significant changes lately, which have caused tampers ergonomic qualities to be improved significantly in a way that the operator’s fatigue is diminished noticeably and Hand-Arm Vibration Syndrome (HAVS) risk is minimized.

- Vibration Reduction Mounts: Models with the available option of heavy-duty shock mounts in the handle system are highly recommended; these mounts essentially separate the operator’s hands from the source of vibration, i.e., engine, so that prolonged work does not cause fatigue.

- Proper Footwear and PPE: The foot of the tamper if allowed to accidentally hit the operator’s foot, can cause severe injury and therefore, in addition to the emergency protection boots with metatarsal guards, the operators are advised to also use hearing protection because of the noise from the engine.

- Stable Stance and Grip: It is advised that the operator, maintain stable position by distributing his weight evenly through the soles of the feet in a way that they are approximately at the same distance as the shoulders, and by doing that he can soften the hold on handle slightly, not in a way that he loses the control of machine but rather that the machine is working for him/not against him.

Essential Maintenance for Long-Term Performance

Nothing is impossible for a vibratory tamper that is regularly and properly maintained by the road crews between their operation hours. Being in some of the most extreme places in terms of dust and harshness and withstanding such enormous pressure constantly, engines require special care and attention.

Failure to carry out regular maintenance tasks will result in the untimely breakdown of the equipment and that will consequently hurt the road crew’s profitability.

- Air Filtration System: As the first line of defense against dust the air filter requires the highest priority in terms of cleaning and monitoring. If it is too dirty and it cannot perform as it should, it will choke the engine and eventually ruin the cylinder.

- Lubrication of the Bellows: The reciprocating piston mechanism is housed within protective bellows and if it leaks oil you can expect the components inside to wear out quickly; regularly check the oil level and replenish it as required for smooth operation of connecting rod and gear.

- Shoe Inspection: Most of the impact force goes through the shoe, normally made of wood or plastic laminate. Regularly check for any signs of separation of the layers, the presence of cracks or looseness of bolts. The shoe not only needs to be replaced if damaged but will also affect the compaction force if it’s unbalanced.

Maximizing Efficiency with the Right Technique

Having a vibratory tamper is just a beginning; what sets apart the professional crew from the amateurs is the use of it. The end result is reaching the same level of density everywhere. For that, a systematic and well-thought-out plan is necessary. An operator should not try to fight a machine or to force it to move faster than it is designed to do.

The tamper with each jump moves forward, and the operator is there to simply guide it. Correct operation results in soil compaction meeting what is expected from engineering, hence no expensive callbacks or sinking of roads later on.

- Layer Thickness (Lifts): For most tampers the thickness of the lift should be between 6 and 12 inches normally, with some exceptions made for type of soil and weight of the machinery, so layering should not be skipped for the sake of saving time.

- Overlapping Passes: The best method for a perfect job is to have overlaps between passes of a few inches and cover from one end to another, lasted by 3-4 passes for maximum density.

- Moisture Control: The perfect amount of soil moisture is what makes compaction possible—without it, particles don’t bind; if they are too dry it’s like a water shortage; if they are too wet, then the water will separate the soil after all. In road construction, the water source is usually nearby for soil conditioning if and when necessary.

Choosing the Right Vibratory Tamper for Your Project

It is not a matter of simply selecting the cheapest or the most powerful vibratory tamper, but one has to consider various elements which include the kind of engine (2-stroke or 4-stroke), the weight of the equipment, and the size of the shoe.

Although the 4-stroke engine is becoming the standard in the industry due to its low emission and ease of use (no need to mix oil and gas), some crews will still opt for 2-stroke units for their feature of continuous operation at different angles without oil starvation.

- Engine Preference: Four-stroke engines are better for environmental friendliness and ease of fueling, while two-stroke engines are your choice when you want lightweight maneuverability and all-angle operation without oil starving issues.

- Impact Force: You should purchase the machine with the greatest impact force if you have to compact heavy clay soils. It is important to check and compare the impact force specifications (usually in pounds or kN) before making a purchase decision.

- Shoe Dimensions: Choose shoe width based on the size of your narrowest trenches. The standard shoe width is 11 inches, but you have the option of 4-inch or 6-inch narrower shoes for specialized utility jobs.

FAQs

What is the main difference between a plate compactor and a vibratory tamper?

Major differences rest in the methods of compaction and soil areness suitability. A vibratory tamper (jumping jack) applies strong vertical forces to compact clay and silt, ideal for deep compaction and narrow trenches. A plate compactor uses high-frequency vibration to compact sand and gravel and large-area with shallow layers.

Can I use a vibratory tamper on asphalt?

No, not normally. A vibratory tamper is a powerful tool that can easily damage asphalt, especially due to its small size which may cause dents to hot surfaces. A vibratory plate compactor (vibratory plate with a water tank) or roller is the right type of equipment for asphalt.

How deep can a vibratory tamper compact soil?

The vibratory tamper is famous for deep compaction. It can compact soil layers of 16 – 24 inches effectively, depending on soil type and machine weight. This depth is considerably more than what a standard plate compactor can do, which is about 4 to 8 inches only. Hence the tamper is very important for trench backfilling.

Why is my vibratory tamper engine running but the machine isn’t jumping?

When the engine is on, but the machine is not tamping, the centrifugal clutch is the most common cause. The clutch engages and drives the gear system only after the engine reaches the specific RPM. Other reasons may be a broken connecting rod, stripped gear, or the oil level in the hydraulic leg is low thus no hydraulic pressure for the leg movement.

What type of oil does a vibratory tamper use?

One can say that it depends on the component being referred to. The engine is usually filled with SAE 10W-30 or 10W-40 motor oil (4-stroke models). Meanwhile, the “leg,” i.e., the tamping system, generally uses a certain type of gear or turbine oil for lubricating the spring and piston system. It is highly advised to read the instruction manual from the manufacturer. It is not only the performance that can be affected but also the machine can be damaged if the wrong oil is used in the leg.

Do I need to wet the soil before using a vibratory tamper?

Indeed, moisture content is one of the critical soil compaction factors. The soil should be moist but not muddy. Water acts as a medium between soil particles, facilitates them to slide into each other, and hence, be tightly packed. If soil is bone dry, compaction is poor and a lot of dust is raised by tamper working. When soil is too wet, machine is bogged down and mess is left.

How often should I change the air filter on a vibratory tamper?

Due to the very dusty situations in which they work, it is the norm that vibratory tappers air guides undergo daily inspections. In case of extreme surroundings, the pre-filter might be cleaned or changed every few days, and the main element replacement usually would be as per manufacturer’s schedule (50-100 hours) or straight away if the filter has been physically damaged or it’s extremely clogged.

Finalize Top Choice of Vibratory Tampers for Road Construction:

The stability of earth underneath the establishment is the main factor that determines the success of any road construction. Therefore, a vibratory tamper is not just a regular tool; it is actually the stabilizer in the toughest areas at the job site.

By concentrating the delivery of a strong impact force (high-impact force), it is assured that the trenches, foundations, and cramped places will be in accordance with the rigorous standards necessary for modern infrastructure.

For the road crews, it is a direct currency investment in their company’s safety, durability, and good name if they purchase the high-end vibratory tampers and take good care of them. Be it in the laying of C utilities, or preparation of a curb, the power of a compact vibratory tamper is the force behind it all.

Plate Compactor, Vibratory Tamper, Soil Compaction