Understanding Steam Rollers with Bumps

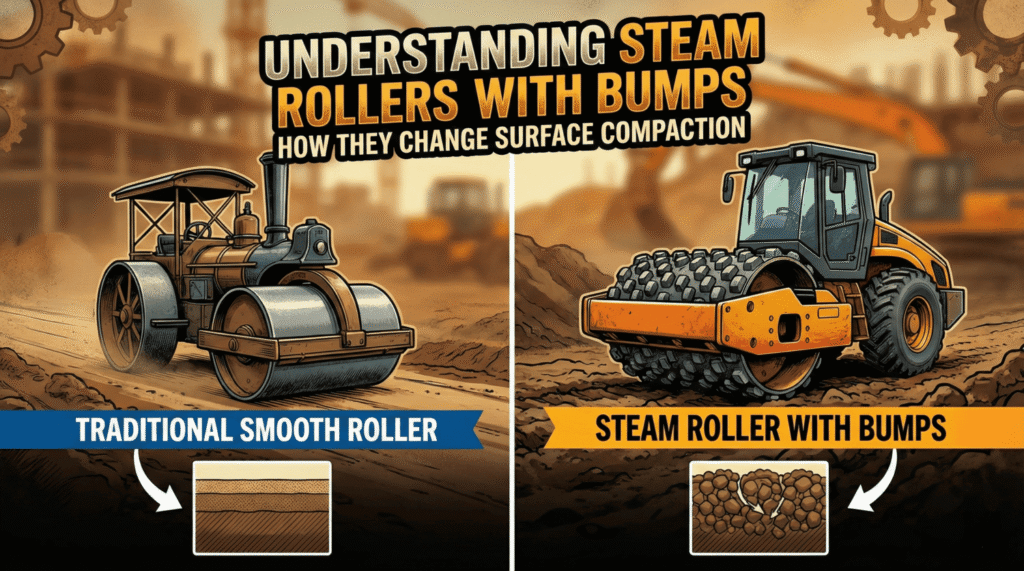

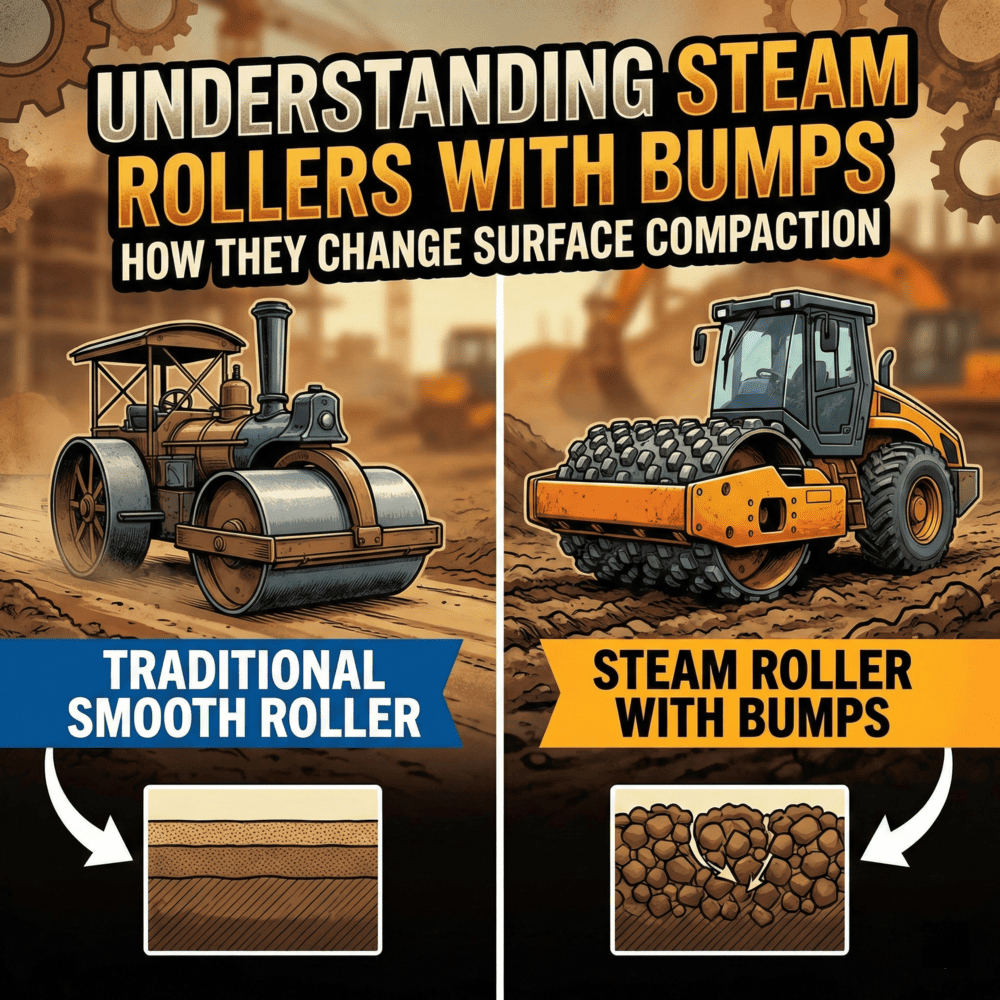

The image of a steamroller flattening a road is probably the first image that comes to mind when most people think about construction equipment. In fact, there’s another type of this heavy-duty equipment that some people may find puzzling: the steamroller with bumps.

Today in the construction industry, such a machine is known as a padfoot roller or a sheepsfoot roller, depending on the shape of the protrusions. Although the word steam roller is a reference to the coal-powered engines used in the 19th and early 20th centuries, the modern compactor is diesel-powered and has gone quite a way.

The bumps or feet on the drum are not there just to be different but are a very critical engineering solution to the toughest ground conditions. The smooth drum rollers cannot do more than just seal the surface of loose materials such as sand and gravel. However, a padfoot roller is made to work the soil deeper.

The instrument first of all uses its unique kneading movement to get rid of air voids and moisture from cohesive soils, i.e., clay and silt thereby, giving a stable base that will not move or crack from the loads later on. Understanding how these machines function can greatly assist project managers and equipment operators in achieving the highest ground stability.

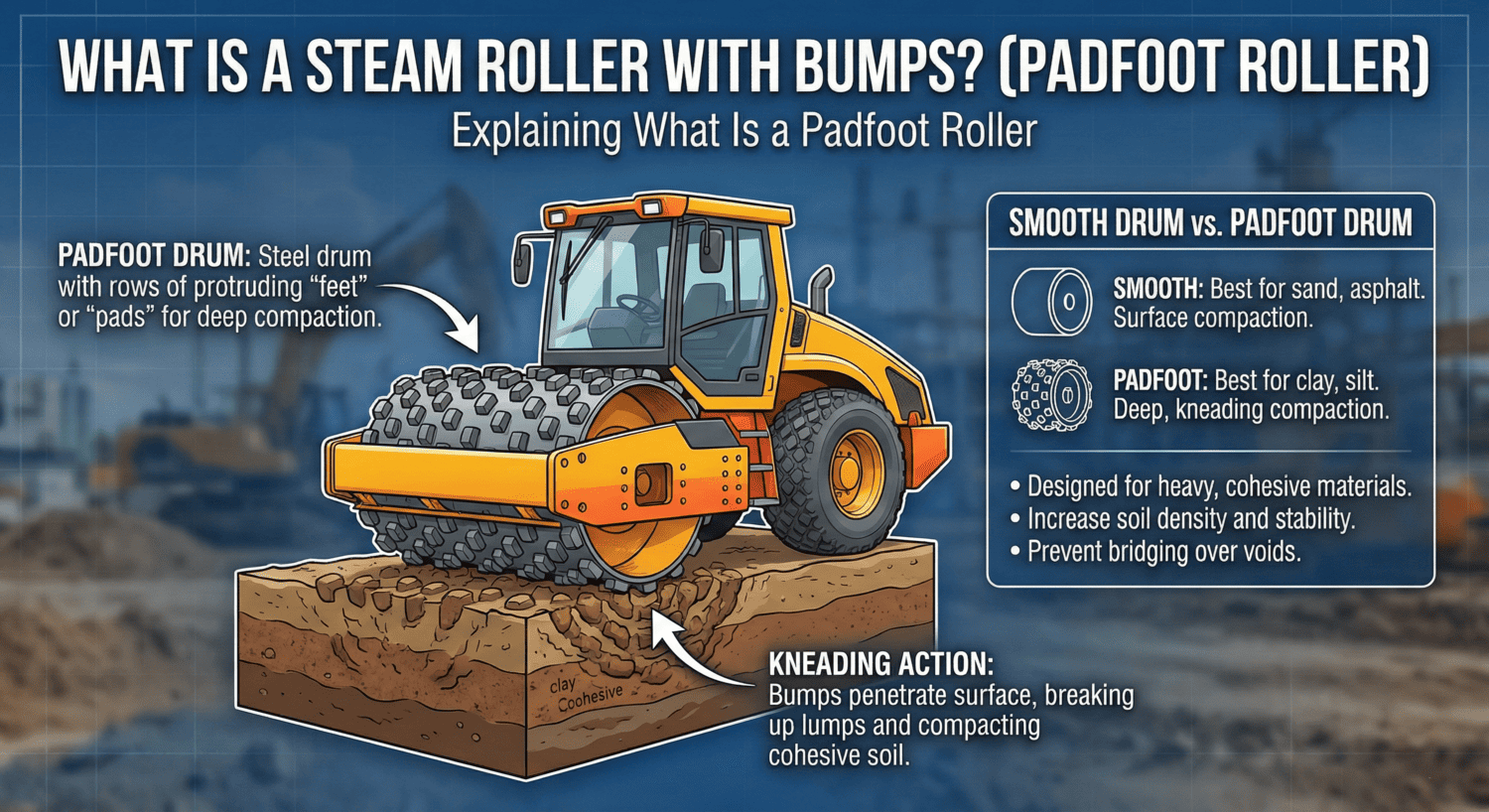

What Is a Steam Roller with Bumps? Explaining What Is a Padfoot Roller

A steam roller with bumps is actually a soil compactor with a studded drum that was found in the pictures. The studs, technically called lugs, pads, or tamping feet, protrude from the surface of the steel drum, and they serve to penetrate the ground.

At that time, the first models were probably horse-drawn or steam-powered, and they were called sheepsfoot rollers because the pattern of impressions on the earth looked like sheep in the mud.

The padfoot roller today marks a leap forward in the development of this idea, making use of geometric, tapered pads that provide better self-cleaning and allow for higher compaction forces. Such machinery is very helpful in heavy civil engineering, as it is able to create a type of compaction that a conventional smooth drum is totally incapable of.

These machines do not only exert pressure on the dirt but also trick the dirt particles into a tightly packed, interlocking arrangement.

- Unique Drum Design: The drum of the padfoot roller is covered in protrusions (pads) made of steel that could be circular, rectangular, or tapered shapes, to name a few, in contrast to smooth rollers.

- Historical Context: The “sheepsfoot” term originated from the old method of using sheep to trample the loose dirt, which became the inspiration for the mechanical “roller with bumps.”

- Primary Function: The main purpose of these compactors is to create very high pressure at the point of each pad so that the pressure can penetrate deeply into the soil.

Science Behind the Pads—Working of Pads

The secret to a padfoot roller’s success is its capability of imparting manipulative force or kneading to the soil. If you take for instance a smooth roller on clay, it will just create a bridge over the hollows with the rolling and seal the surface, thereby trapping the air and moisture.

This is the ideal situation for the formation of what is known as a false compaction, the top surface of which appears to be hard while the subsurface is weak and unstable. The pads on a padfoot roller keep the roller from sealing the surface of the soil.

Much like a baker kneads the dough, the pads penetrate the soil vertically and then as they leave at an angle they thrust or knead the soil. This action separates the tiny clay particles that have strong natural bonds and flattens the microscopic air voids that have occupied the particles thereby making the soil dense and strong.

- Breaking Bonds: There is an increased pressure by the very tip of the pad that helps the disintegration of soil particles to be rearranged to obtain a higher density from the resulting compaction.

- Bottom-Up Compaction: These pads break through the layer to reach and compact the lower layers first, after which they gradually ‘walk out’ of the soil as the layer becomes denser.

- Moisture Control: By continuously increasing the surface area in contact with air and pushing out the water, the kneading action facilitates the effective drying of a damp soil.

Ideal Soil Types: Why Cohesive Soil Needs a Padfoot Roller

Choosing the right piece of equipment depends solely on the kind of soil you are going to work on, and a padfoot roller is definitely the way to go if it is cohesive soil you are dealing with. Cohesive soils, i.e., clay and silt, have the property of sticking to each other and holding a lot of water.

They are plastic (which means that molding and deforming can be done without cracking). When compaction is done on heavy clay with a smooth drum machine, the machine will either slip or slide, or there will be this “pumping” phenomenon that happens where the soil moves like a waterbed in response to your steps.

The tapered pads of a padfoot compactor are made to punch through this resistance. Using a padfoot machine on granular soil like clean sand or gravel has the opposite effect; the feet will just act like a tiller and loosen the sand instead of packing it down.

- Clay and Silt Dominance: These rollers can really make a big difference when used on natural material with a high plasticity index.

- High Moisture Tolerance: The ability of smooth drums to handle soil with very little water is well-known, but padfoot drums can go even further in that respect by preventing the drum from sliding due to the pads that act like brakes.

- Preventing Bridging: It is the small points of each pad that ensure pressure is exerted on the soil structure rather than being on top of hard clumps.

Padfoot vs. Smooth Drum: Comparing the Two

In order to know the real value of a padfoot roller, the best thing to do is to look at it side by side with a smooth drum roller. These days, both machines have the same basic chassis and propulsion systems, but the way they go about being in contact with the ground is different.

The smooth drum depends on both its weight and vibration to cause a settling of particles, a bit like a shaker box. The padfoot rolls across the ground by impacting and manipulating the particles. In many road construction projects, these two machines are used together: one padfoot roller to create the required structural strength and the other smooth drum roller to “seal” the surface by evening out the dimples from the pads so that water can run off it instead of ponding.

| Feature | Padfoot Roller (Sheepsfoot) | Smooth Drum Roller |

| Primary Mechanism | Kneading and Impact (Manipulative Force) | Static Pressure and Vibration |

| Best Soil Type | Cohesive (Clay, Silt, Heavy Soil) | Granular (Sand, Gravel, Asphalt) |

| Surface Finish | Dimpled, rough texture (increases friction) | Smooth, sealed surface |

| Compaction Direction | Bottom-up (Walks out of the lift) | Top-down (Surface pressure) |

- Energy Transfer: The energy from the padfoot roller is transferred deeper into the lift because of the pads’ smaller surface area, which results in a higher PSI (Pounds per Square Inch) being created.

- Traction: The lugs allow for outstanding traction on very slippery wet clay slopes, where even going uphill with a smooth drum would be a struggle.

- Layer Integration: The dimples left by a padfoot roller are an excellent ‘key’ for the top layer to adhere to.

Operating Techniques for Maximum Density

Operating a padfoot roller involves certain techniques that ensure that the bumps are really effective in their work. What the operator does first is to observe closely the walk-out phase.

When a new layer of soil in its loose state is laid down, the pads of the roller will be able to penetrate deep into the material. As the soil compacts from the bottom-up and the drum reaches the surface, the pads will penetrate less and less. The roller will eventually “walk out” of the soil by traveling on the tip of the pads.

This is one way that the operator can know that the layer has been sufficiently compacted. Also, the operator should not forget the speed factor; if you go too fast, the pads may not have the time to fully penetrate and knead the soil; on the other hand, going too slow may result in over-compaction, which could in fact lead to the soil structure being broken.

- Monitoring “Walk-Out”: The operator can monitor the increasing height of the drum on the surface, which is the indication that the bottom layers are fully compacted.

- Speed Management: For vibratory systems and pads to have enough dwell time to manipulate the clay, a slow and steady pace (usually 2-3 mph) is the best one.

- Pattern Overlap: To prevent any ‘uncompacted soil’ streaks from remaining between the pad rows, the operator must overlap the passes by at least one-third of the drum width.

Maintenance and Wear of the Drum Lugs

The bumps on a padfoot roller are not only subjected to abrasion and impact but also require maintenance for the machine to keep performing well. With time, repeated working in abrasive soils leads to the pads’ height and shape being worn out. When the pads are short and rounded, the parts of the pads can no longer go deep into the soil to mix it like before, so the effect of the drum is only pseudo-smooth.

On the other hand, sticky clay might clog the pads so heavily that it is impossible to separate one from the other. Therefore, the drum would be like a solid cylinder of mud, and the pad’s penetration power would be nonexistent. In response to this wear problem, the large scraper bars are now being fitted on modern padfoot rollers.

These are steel blades positioned around the drum that, in a way, act as the external fingers of the drum, which clean the mud off the drum throughout the entire revolution.

- Scraper Bar Adjustment: Proper adjustment of the scraper bars is done such that they are kept in very close proximity to the drum surface in order to prevent material build-up between the pads.

- Pad Restoration: Old pads could be fixed by re-welding or changing to new ones of the geometric shape, size, and penetration depth that they had originally.

- Hydraulic Health: Padfoot rollers work against resisting forces that are very high. Therefore, the hydraulic motors have to handle really high loads and so frequent checks of both the fluid and filters are necessary.

Applications and Project Suitability

The padfoot roller is very much the primus inter pares of heavy earth-moving and infrastructure projects. You wouldn’t typically find it paving your home’s driveway, but rather it will be almost everywhere on enormous civil engineering sites. For instance, they play a crucial role in earthen dam construction, where the clay core must be watertight because only a very few feet of separation exist between the public and the water.

The same is true of landfill construction, where they are used to compact waste and clay liners so as to prevent the leaching of hazardous substances into the groundwater. In highway construction, these rollers are used in the preparation of the sub-base, i.e., the deep natural soil that lies under the gravel and asphalt.

Without the deep compaction that a padfoot roller is capable of, the highway above would be subject to buckling as the clay under it settles or shifts with moisture changes.

- Water Retention Structures: Their use is indispensable at dams, levees, and reservoirs to keep the permeability of the soil at a minimum through dense compaction.

- Road Subgrades: In order to stabilize natural ground before laying any aggregate or pavement on it.

- Trench Backfilling: Smaller, remote-controlled trench rollers (usually having padfoot drums) are used to safely compact soil in deep utility trenches.

FAQs

What differentiates a padfoot from a sheepsfoot roller?

The latter is a static machine with cylindrical legs and is mainly used for semi-cohesive soils. A modern padfoot roller has geometric pads that are typically tapered and is made to use vibratory force, which makes it more effective in highly cohesive clays and also compact faster and with more force.

Can a smooth drum be effective on clay soil?

You should definitely not try that, as a smooth drum will be prone to “bridging” over soft spots common in clay while forming a hard layer on top, thus sealing the surface without compacting the sublayers. The consequence will be settling later on. In order to get rid of air pockets and moisture and level off the foundation, the padfoot roller needs to penetrate and knead the clay.

What is a steam roller with bumps called?

Technically speaking, a “steamroller with bumps” is a padfoot roller or tamping roller. A long time ago these were sheep’s foot rollers. However, in the industry they are known as “padfoots” or soil compactors with a padfoot shell kit.

What is the purpose of a padfoot roller having bumps?

The bumping or pad-shape feature goes deep to the soil surface; penetration and compaction is thus done from the bottom up layer. Concentrate the roller’s weight into small areas (the tips of the pads), which promotes the pressure so high that it breaks the bonds of the sticky soil particles and pushes them together.

How many rounds should a padfoot roller do?

There is no definite answer to the question as the number of passes depends mainly on the soil type and moisture content, but as a rule of thumb, it is said that a padfoot roller needs 4 to 8 passes to achieve the desired density. The driver/operator normally looks out for the machine to “walk out” of the soil; this situation refers to the pads no longer sinking deep into the soil indicating the soil being compacted.

Can a padfoot be used on asphalt?

A padfoot roller is the absolute no faire on a surface that is asphalt. The metal pads will be the ones to tear apart the smoothness of the asphalt. Puncturing it and breaking the pavement structurally will be the end result. Smooth drum or pneumatic tire rollers are the ones that can be used for asphalt compaction.

Which is the best roller for wet dirt?

The Padfoot roller is best suited for wet, clinging dirt. Pads can enter and exit a wet soil without being trapped by the machine due to their shape. On top of that, the kneading process helps the soil surface area to be more exposed and therefore aids the drying out of soil.