Steam rollers with their iconic bumps and robust structure, are a major chapter in the heavy machinery evolution, the one that still influences the ways of the construction. These retro machines, which are the outcome of 19th-century engineering brilliance, have become the ultimate source of inspiration for the compactors and rollers of our era.

About Steam Rollers:

We cannot forget that the conventionally used steam roller is still very much alive and well as a monument of the great tactic of a simple and at the same time efficient solution and the extraordinary skill of historical engineering, even though the old steam roller has been replaced by advanced machinery.

Their legacy is among the very clear landmarks, which prove that the marvels of the past have served as the foundation for the future of the construction industry evolution.

The Historical Significance and Evolution of Steam Rollers

Historically, steam rollers were among the first self-propelled compacting machines, transforming road construction from labor-intensive manual work into an efficient process. The introduction of steam-powered rollers towards the end of the 19th century was a landmark in engineering that greatly sped up and enhanced the quality of road surface preparation.

The machines, which were often distinguished by their big wheels and bumps – the latter being used to increase the vibration and thus the compaction – became the main tools for the establishment of long-lasting roads and highways.

The progression from horse-drawn rollers to steam-powered behemoths was due to the desire for more power and greater efficiency. The first products, for example, those made by Aveling and Porter, exemplified the power and invincibility of steam technology, which was still used up to the middle of the 20th century.

The appearance of internal combustion engines led to the further evolution of the machines, thus the steam rollers were substituted with the diesel-powered ones that were more controllable, dependable, and efficient.

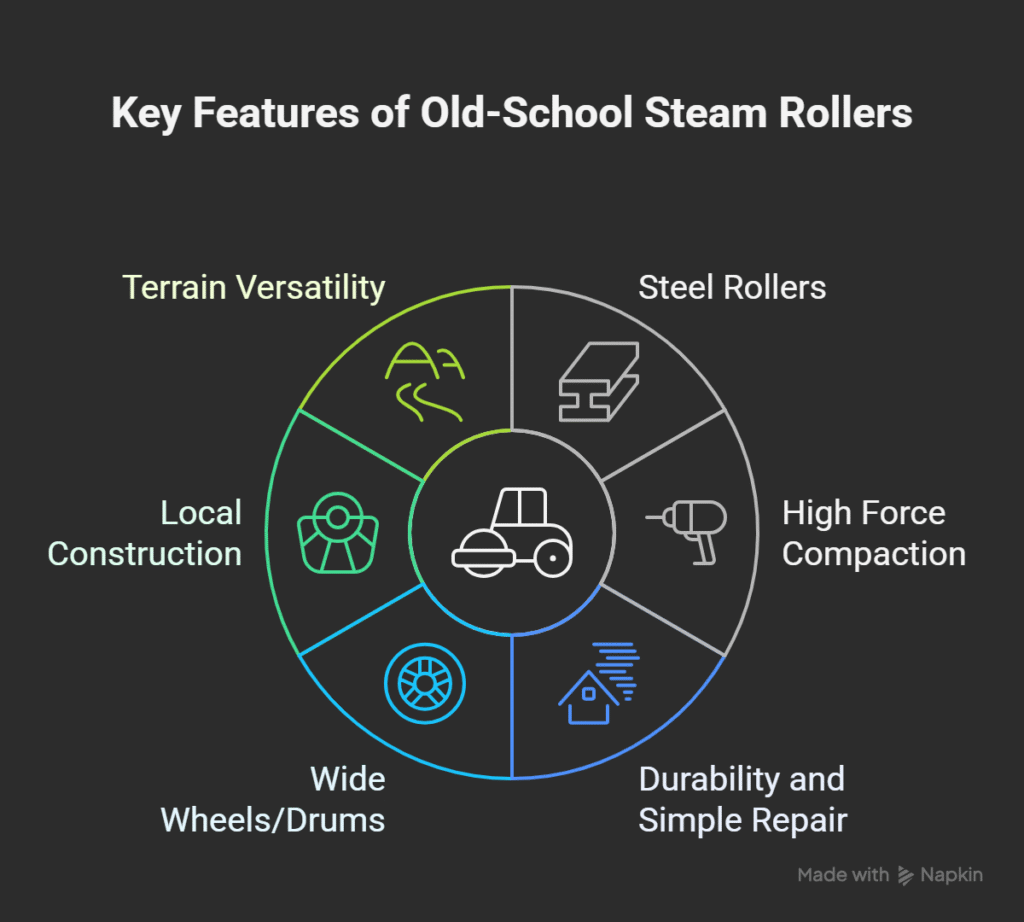

Key Features of Old-School Steam Rollers:

- steel rollers that were massive and of a coarse nature with wide raised areas for vibration to be increased

- The rollers were able to deliver a very high force for dense compaction because they were powered by steam engines.

- Parts for them were hard to find and their main feature, which was durability, was the main theme of their builder, and repair was very simple

- They had wide wheels or drums to spread the weight and get better surface contact

- Most of these machines were built locally to meet the requirements of local construction and engineering practices.

- They were constructed to deal with various types of terrain as well as different kinds of surface materials

Engineering Marvels: Design and Functionality

The simple yet effective design of these old machines is what made them vintage engineering marvels with a lasting impact.

The protrusions on steam rollers—sometimes named “bulldogs” or “lumps”—are not there to beautify but are an integral part of the machine’s engineering. They emit the vibratory forces that make the compaction of soil, asphalt, and other construction materials possible. Such a design gives the possibility for more even and efficient force application for a more uniform surface density, which is a principle still used in modern rollers.

Contemporary designers of heavy equipment still laud the design genius of these antique models, which used mostly weight and vibration instead of sophisticated electronics. Because of this design, they became exceedingly sturdy, a factor that allowed them to be used in difficult conditions and minimally serviced. Their large drums and bumps were instrumental in achieving the tightly compacted and evenly finished surfaces necessary for road construction and foundations.

Benefits of the Traditional Design:

- They have high durability and can frequently live for a period of several decades with a good upkeep

- Their functioning is simple, and they can be used by operators who have different levels of skills

- Maintenance costs are relatively low, especially in comparison to modern machines that are electronically controlled

- Able to be used effectively in various terrains and surface types without any difficulties

- Being in existence for a considerable length of time and having been used extensively, these machines have been shown to be capable of producing durable roads and paved surfaces

Essential for projects where simplicity and reliability are chief considerations for the best output.

Modern Impact and Continuity

The main concepts of the old steam rollers which have been preserved through time and are still used in vintage steam rollers are core principles that modern technology has not been able to change effectively. Several features of the modern compactors like bumps, vibration, and mass effects can be traced back to the old-school designs.

For example, the tops company have developed advanced machines that, while more sophisticated, still incorporate the basic engineering concepts of their historic counterparts—vibratory force, strong build, and efficient material handling.

Actually, the heritage of these old machines can be seen in the design philosophy of present-day models that focus on robustness, simplicity, and operational reliability. They remind us that sometimes, solving engineering problems in an old-school way is still valid, providing good efficiency and practicality that modern designs are still taking and refining.

The Cultural and Industry Influence

Aside from their technical features, the steam rollers with bumps have also become cultural icons standing for the industrial progress. The old films and museum exhibits present these machines as the essential tools that have been used in the building of the present-day infrastructure.

The industry pioneers’ nostalgia and respect to the engineering marvels of the past can be seen at special events like “Last Blast” vintage construction equipment shows where these machines take center stage.

In the realm of current construction, those historical machines are the symbols of the engineers’ resilience and mastery of the craft. They are still used for educational and heritage purposes as they show how the age-old designs, while they are getting technologically outdated, are still having an effect on the current practices and are a source of new-engineering solutions.

Impact on Industry and Education:

- Recording the past of engineering and the use of old skills

- Changes in the modern world of design being influenced by the innate features of the old things which are simplicity and durability

- Materials for learning that open up the training of future engineers and operators

- Recognition of the cultural side through industry museums and exhibitions

- Market for the collection of old parts and restoration projects

- Awareness of the fundamental elements such as mass, vibration, and simplicity

Steam Roller FAQs

What is a steam roller, and how does it differ from modern rollers?

A steam roller is a kind of road compactor that can be powered by steam or an internal combustion engine; it is also distinguished by its massive wheels and bumps for vibratory compaction. Despite modern rollers being equipped with state-of-the-art electronics, they still operate on the principles of mass and vibration.

Why are the bumps on steam rollers called “bulldogs” or “lumps”?

The bumps serve to increase the vibratory force transmitted during compaction, leading to the production of dense and even surfaces – the feature without which modern vibratory rollers would not be possible.

How long have steam rollers been used in construction?

They have their roots in the late 1800s when they were horse-drawn models later converted to steam-powered machines, and they had their golden age between 1900 and 1970.

Are vintage steam rollers still useful today?

While they have largely been substituted by contemporary machinery, old rollers have been kept in museums and heritage events due to their historical value and robustness.

What were the strengths of traditional steam rollers?

One of the major factors behind the long career of these machines is their robustness, which goes along with simplicity, durability and the ability to work effectively on different kinds of terrains making the handful of them-practitioners-icons in the industry for decades to come.

Could steam rollers be used in modern construction projects?

In a few niche applications and restoration projects, old steam rollers can still be put to use. However, modern compactors are chosen for efficiency and standard compliance.

What lessons can modern engineers learn from vintage steam roller design?

They are a good example of how important it is to be simple, robust and efficient in the way the force is used – all these principles are very much alive in contemporary engineering and machinery design.