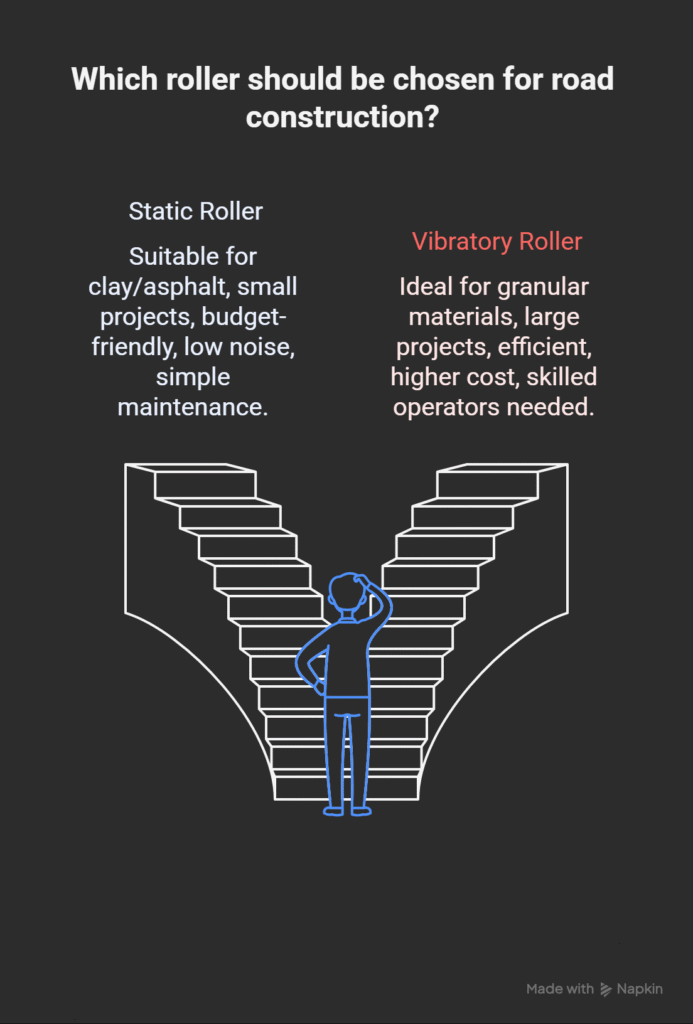

Choosing the right compaction equipment among static roller vs vibratory roller is one of the most important decisions in road construction. A decision to choose among static roller vs vibratory roller can have a substantial effect on the quality, longevity, and cost-effectiveness of your project.

Both static roller vs vibratory rollers are machines designed to compact soil, asphalt, and other materials but differ in their operation and the application they are suitable for. This article compares, benefits, and disadvantages of the two, and also helps to decide which roller is best for your road construction needs.

Understanding the Basics: Static Roller Vs Vibratory Roller

For starters, let’s figure out what makes these two kinds of rollers different.

-

Key Features of Static Roller:

A static roller is a heavy compactor that uses only the weight of the machine to press and compact materials. It achieves the compaction of soil and asphalt by the static pressure of its heavy drum(s) without any vibration.

Advantages of Using Static Rollers

- They are mainly appreciated for their uncomplicated nature and the capability to satisfy specific compaction requirements that are inherently part of the static rollers.

- By their operation and application, these rollers are capable of achieving good compaction results when done on smooth, cohesiveness materials like clay and asphalt.

- During their work, these machines produce less noise, and hence, they are suitable for use in residential areas and noise-sensitive places.

- Additionally, static rollers are safe for fragile surfaces as well as medial constructions that are sensitive to vibrations such as old buildings or bridges.

Key Benefits

- Lower initial purchase and maintenance costs because the machine has few parts that wear out.

- Simple and easy to operate and maintain and thus few wasted hours during downtime.

- Great for use in small projects as well as leveling of smooth surfaces.

- With fewer parts that can break, a static roller will still produce decent results and has a long operational life if taken care of properly.

-

Key Features of Vibratory Roller:

A vibratory roller utilizes its weight along with a rapid vibration mechanism that produces a high number of impacts per second, thus allowing it to compact materials to a greater extent by the process of shaking and settling the particles tightly.

Advantages of Vibratory Rollers

- Most of the time, vibratory rollers are selected for their higher efficiency of compaction and great effectiveness when used on granular or loose materials.

- Firstly, the vibrations produced help to remove the air that was taken up by the voids in the loose soil or aggregate, thus they become dense and stable.

- Additionally, vibratory rollers work at a much greater speed when compared to static rollers thus the time for the whole project is minimized.

Moreover, these are also very versatile machines and can be used for a broader range of soil types. The dirt can be pure sand, gravel, or even a mixture of different kinds of soils.

Key Benefits of Vibratory Roller

- More complete soil stabilization that can be achieved both deep and thorough leading to higher quality of compaction.

- Stacks up more benefits in terms of mobility and versatility when it is used on various different terrains.

- Such kind of machines can be used for heavy-duty industrial and commercial projects like large-scale road construction and the like only.

However, these types of machines call for skilled operators and frequent maintenance due to the presence of their vibration units in them.

Detailed Comparison: Static Roller vs Vibratory Roller

Check the table for the detailed comparision among static roller vs vibratory roller. Here are the factors and features which vary in their specifications.

Factors to Consider When Choosing a Roller for Road Construction

This table shows the fit of a certain roller with factors visualizing project and kind of work considered.

| Feature | Static Roller | Vibratory Roller |

|---|---|---|

| Operating Principle | Uses weight for compaction | Uses weight + vibration for compaction |

| Ideal Material | Cohesive soils & asphalt | Granular soils, loose and mixed materials |

| Noise Level | Lower noise | Higher noise due to vibration |

| Cost | Lower initial and maintenance costs | Higher initial cost and maintenance expenses |

| Speed & Efficiency | Slower | Faster compaction with better depth |

| Impact on Surroundings | Gentle on structures and noise-sensitive areas | Potentially harmful vibrations to nearby structures |

| Maintenance Complexity | Simple, fewer moving parts | Complex due to vibratory components |

| Suitability | Small to medium projects, smooth surfaces | Large projects, rough terrain, mixed materials |

Factors to Consider When Choosing a Roller for Road Construction

The decision to pick up one roller over another should be based on the analysis of the most essential factors that are:

- Material Type

- Static rollers will effectively condense such materials as clay or asphalt.

- Meanwhile, vibratory rollers are the only machines that can do a good job of solidification of granular or loose materials like sand and gravel.

- Project Size and Scope

- Small-scale or residential projects are often benefited by the use of static rollers due to their lower noise and cost.

- Large highway or commercial projects on the contrary demand vibratory rollers that are used for speed and efficiency.

- Budget Considerations

- One can purchase a static roller at a reasonable price, which makes it a budget-friendly pick at the initial point. Static rollers also take less time in-between maintenance sessions, thus further adding to the savings.

- On the other hand, the owners of vibratory rollers need to make provisions for a higher initial cost coupled with regular upkeep costs although such a machine will facilitate project completion within a shorter period.

- Site Conditions and Environmental Impact

- Besides being a silent neighbor in terms of noise production, static rollers do not give off harmful vibrations and can, therefore, be used near fragile infrastructures or places where silence is required.

- Although vibratory rollers are relatively efficient in their work, they may not be allowed to operate in such areas if there are a lot of noise and vibration-sensitive buildings around.

- Operator Skill and Maintenance

- Static roller machines are very simple and require minimal skills for the machine operator, and they are also cheap to maintain.

- Operators of vibratory roller machines should be highly skilled while the tasks of periodical maintenance and checking for the condition of the vibration assemblies should be done more frequently for the rollers initiating vibration.

An understanding of these factors will enable the company’s project team to select the right equipment that aligns with their project goals, timeline, and budget.

Features And Uses of Static Roller vs Vibratory Roller:

When to Use Static Rollers in Road Construction

- Static rollers are ideal in certain situations that fit well with their operational features.

- By producing a uniform smooth non-vibrating layer of finish, rolled asphalt surfaces can achieve their final target of being solid and waterproof.

- Projects in areas like residential neighborhoods or noise-sensitive zones.

- Compacting cohesive soils that don’t react much to vibrations.

- The working place might be near some old buildings or the infrastructure is delicate, so, in order to avoid structural damage, static rollers should be used.

Reasons to Choose Static Rollers

- Cost savings when it comes to small and medium-sized jobs in the field of road construction.

- Low maintenance downtime due to the machine’s ease of use.

- Environmentally friendly due to reduced noise and the absence of vibrations.

When to Use Vibratory Rollers in Road Construction

Most of the time, vibratory rolls are chosen for their capabilities that go beyond the basics and are able to effectively deal with demanding tasks.

- Road construction projects on a large scale that require deep and uniform compaction.

- Working with loose granular materials such as gravel, sands, or mixed soils.

- Projects where faster compaction rates can significantly reduce labor and time costs.

- Areas where soil stability is crucial to support heavy traffic loads and infrastructure longevity.

Reasons to Choose Vibratory Rollers

- Highest compaction quality and efficiency.

- Adaptability to work with various materials and terrains.

- Capability to be used as heavy industrial machinery in large-scale commercial road projects.

Maintenance and Operational Tips for Static Roller Vs Vibratory Roller

One of the most important things that a roller compactor owner should do is to maintain the machine properly so that it will not only give a long service but also be safe and efficient.

Static Rollers:

- Frequently examine the surface of the drums and frame for wear or eventually damage.

- Maintain the hydraulic and engine systems in good condition

- Ensure the operators are trained in the proper handling of the machine so as to avoid uneven compaction

Vibratory Rollers:

Along with frequent inspection, the vibrating parts should also be properly lubricated to ensure good functionality.

- Keep a close eye on the condition of the engine and hydraulic systems.

- Wear personal protective equipment when exposed to noise and vibration

- Monitor the wear of the parts following the manufacturer maintenance schedule

Summary: Which Roller is Better? Static Roller Vs Vibratory Roller

It’s not possible to give a definitive answer that fits all cases to choose between static roller vs vibratory roller. The choice of the best roller for road construction is determined by the factors such as the type of materials, the size of the project, the environmental restrictions, and the budget.

Static rollers are less expensive and are more suitable for smaller projects that are sensitive to noise or made of cohesive materials. Vibratory rollers, on the other hand, can perform better in surface compaction of large projects with different types of materials, but they require a higher initial investment and maintenance.

Making the right choice will lower your expenses, increase the lifespan of the road, and enhance the safety of operations.

FAQ: Static Roller vs Vibratory Roller in Road Construction

What is the main difference among Static Roller vs Vibratory Roller?

Static rollers do the job of compaction only by the weight they hold, whereas vibratory rollers combine the weight with the vibrations for more efficient compaction.

Which roller is more suitable for asphalt paving?

Static rollers are perfect for asphalt paving as they can give continuous, homogeneous compaction without any vibration damage.

Are vibratory rollers noisier than static rollers?

Yes, a vibratory roller emits more noise and vibration, and this can be a problem in a residential or noise-sensitive type of areas.

Which roller is better for cohesive soil compaction?

Static rollers are good performers on cohesive soils like clay.

Can vibratory structures damage nearby structures?

Yes, the vibrations can eventually cause damage to old or delicate structures; hence, the necessary precautions should be taken.

Are vibratory rollers more costly in maintenance?

Yes, it is due to the complicated vibration mechanism they need more frequent maintenance than static rollers.

Which decisions should I take when I want to rent or buy a roller for my road project?

Think about the size of your project, the type of soil, the budget, and the environmental factors to select the roller that is most suitable for you.