For your upcoming land-moving, road-building, or soil compaction project, it is essential to select the right roller to achieve the best result of your work by choosing between sheepsfoot roller vs. smooth drum roller.

Among compaction rollers, one of the leading types is a sheepsfoot roller or consequently a padfoot roller and the other is a smooth drum roller. Knowing their different behaviors, applications, strengths, and limitations, you will be able to make your project work effortlessly and yield long-term benefits.

What Are They?

Sheepsfoot Roller (Padfoot Roller)

A heavy roller drum which is manufactured with protrusions (“feet” or pads) that are similar to a sheep’s foot; these feet insert the soil, making the volume reduced tightly, and most of all deeply, e.g. in cohesive or semi-cohesive soils.

Smooth Drum Roller

A roller of one or two steel drums with smooth sides. The machine presses clean and regular over the surface, which is perfect for the compaction of granular materials such as sand, gravel, and asphalt.

Roller Design & Mechanism

Sheepsfoot Roller

- A drum with numerous small protrusions that penetrate and knead into the soil.

- Exclusive foot penetration is usually present in the static and vibratory versions; the vibratory models through combining foot penetration with vibration achieve the higher effectiveness of compaction.

Smooth Drum Roller

- Flat steel drums—single or tandem

- The vibratory version utilizes the weight with the vibration to achieve the even, deep compaction.

Soil Type & Application Suitability

Sheepsfoot Roller – Best For:

- Soils that are cohesive or semi‑cohesive in nature such as clay, silt, wet mud, fine‑grain materials.

- Water‑table that is of high value or dam embankments: it is very good in compressing heavy, sticky soils that are wet.

- Sub‑grades and under‑layers which are undergoing deep compaction and need high density for infrastructure and road foundations.

Smooth Drum Roller – Best For:

- Non‑cohesive, granular materials such as sand, gravel, limestone, ballast, and asphalt.

- Finishing at the surface-level, removing bumps and creating smooth, level surfaces.

- Open areas that are large such as roads, driveways, parking lots, foundation bases, and backfill compaction.

Performance & Efficiency

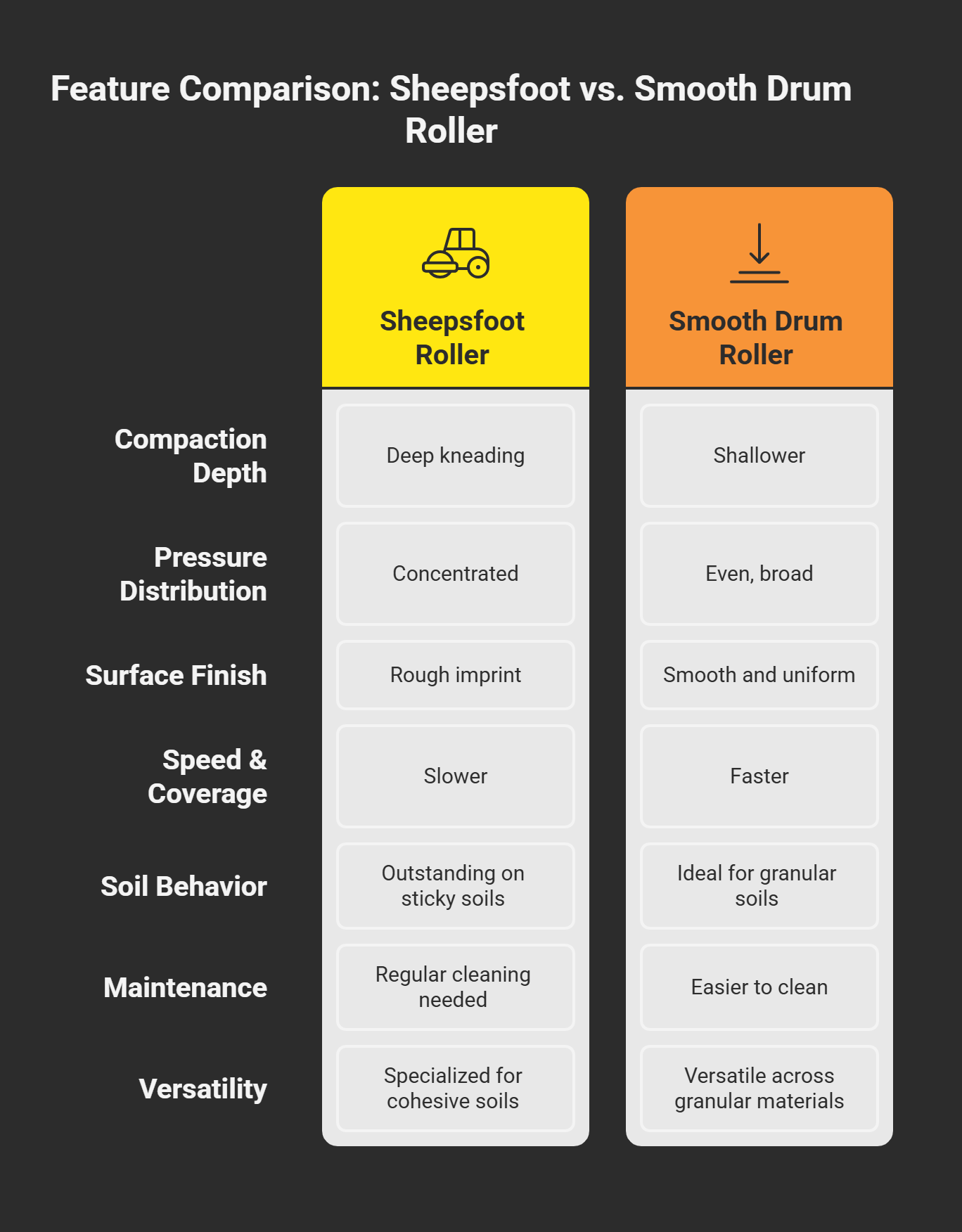

| Feature | Sheepsfoot Roller | Smooth Drum Roller |

| Compaction Depth | Deep kneading; high density in cohesive soil | Shallower; ideal for surface-level granular compaction |

| Pressure Distribution | Concentrated at individual ‘feet’ | Even, broad pressure across drum |

| Surface Finish | Rough imprint; requires further smoothing | Smooth and uniform finish |

| Speed & Coverage | Slower; more passes needed | Faster; large-area coverage |

| Soil Behavior | Outstanding on sticky, clingy soils | Ideal for loose, granular soils |

| Maintenance | Feet require regular cleaning and upkeep | Easier to clean; smooth surfaces maintainable |

| Versatility | Specialized for cohesive soils | Versatile across granular materials |

FeatureSheepsfoot-RollerSmooth-Drum-Roller

When to Choose the Best Roller?

When to Choose Sheepsfoot Roller:

- Building dam embankments or levees: Provides density and durability required for water retention projects.

- Road sub‑base preparation: Compacts fine-grain substrates to avoid future settling.

- Construction on clay-heavy or cohesive soils: Ensures deep compaction where smooth drums fail.

When to Choose Smooth Drum Roller:

- Asphalt or concrete paving: Ensures even, polish-like surface finish.

- Compacting sand, gravel, or rock base layers: Efficient and effective across wide, granular surfaces.

- Large-scale open surface grading: Fast area treatment with regular pressure transmission.

Maintenance & Operational Tips

Sheepsfoot Rollers

- Try to keep the feet clean to prevent any sticking or clogging of the parts.

- Check the wear of the projections regularly and if necessary, do the sharpening or replace the worn-out ones.

- Make sure the vibration mechanism (if any) is functioning properly.

Smooth Drum Rollers

- One of the most important aspects of drum surface and scrapers is to carry out a regular inspection.

- You can use ballasting (water or sand) to rest the drum on the right compaction requirements by adjusting it.

- Just like the case of the Solution Plant Hire, Newman Tractor, maintain the lubrication of the bearings and vibration until your machine runs evenly and smoothly.

Choosing Between Rental & Ownership

- Rent If:

Projects are short-lived or soil types differ between the jobs. In case you only require one type of equipment at a certain stage but at another stage, you need the opposite type, then the rental will facilitate your work by giving you access to both.

- Buy If:

- Projects are long-term and soil types are uniform across jobs.

- You definitely need both types of rollers for different phases, so ownership is more convenient than rental.

- Your operation consistently compacts similar soil types in the same volume, thus supporting ROI.

- Long-term cost savings significantly exceed the initial investment.

- Sheepsfoot Roller Vs. Smooth Drum Roller – Summary Breakdown:

Sheepsfoot Roller – Key Highlights

- Most suitable for cohesive materials like clay and silt.

- Deep compaction by the principle of kneading.

- Along with dam embankments, sub-grades are good areas for the application of this technology as well as the compaction of the heavy sub-base.

The treated part of the surface gets a rough texture; thus the step of smoothing the roller is very common. Because of drum protrusions, the maintenance routine is more time-consuming.

Smooth Drum Roller – Key Highlights

- The smooth and flat drum is designed for uniform compaction of materials.

- The best way to treat granular soils like sand, gravel, and asphalt is with the use of a smooth drum roller.

- The preparation of the surfaces such as roads and pavements is the application where this machine is perfect for.

Speedy full coverage with a smooth finish in fewer passes is the main advantage of this method. It is relatively simple to carry out its maintenance routine; the weight can be adjusted by ballasting.

Sheepsfoot Roller FAQs

What is the difference between padfoot and sheepsfoot rollers?

While often used interchangeably, sheepsfoot rollers typically have longer, cylindrical feet that fluff the soil and assist drying, whereas padfoot rollers have shorter, more geometric pads that compact without fluffing.

Can you use a smooth drum roller on clay soil?

Definitely, but it is a very ineffective method. Clay might get stuck on the roller and the surface is compacted only partially. So the sheepsfoot type of roller is the one which is the most appropriate for this kind of soil.

Do smooth drum rollers always vibrate?

Not at all—there are static (weight only) and vibratory rollers. The latter utilizes vibration to deepen density and increase the compaction depth.

How often should I clean a sheepsfoot roller?

After each use, the feet, which are the parts where mud and debris get removed, should be cleaned to continue the function of the machine and also to prevent compaction problems.(Solution Plant Hire)

Are sheepsfoot rollers slower than smooth drum rollers?

In most cases, yes. Due to the fact that they have a kneading effect and the contact points are narrow, they need more passes to be able to spread the load evenly, thus, these types of rollers have a lower speed than the smooth ones.

What’s the best roller for asphalt?

A smooth drum roller, especially vibratory models, are perfect for asphalt work as they create a flat, even surface.

Should I rent or buy a roller?

If you want to have a versatile tool and use it only for a short period, rent a roller. On the other hand, if you compact the same material frequently and the amount of usage justifies, then it is better to buy a roller.

Final Thoughts

Selection of sheepsfoot vs. smooth drum roller is a matter of considering soils, surface finish, speed, and project type. For deep compaction of sticky, cohesive soils use sheepsfoot rollers and for speed and flat surface work on granular materials use smooth drum rollers.

One of the best methods to carry out compaction on https://rollercompactor.net/

Start with a sheepsfoot padfoot roller to densify foundational layers. After that, a smooth drum roller should be used to enhance surface uniformity and finish quality.

As a result of this dual-step method, you have the opportunities of depth and finesse with your projects—from roadwork to foundation prep.