Elevate Your Sheepsfoot Compaction Skills With These Advanced Methods

When it comes to soil compaction, the sheepsfoot roller is the first thing that comes to one’s mind for cohesive soils. However, a plethora of advanced methods that bring the productivity of the standard passes to a higher level i.e. rendering less settlement, ensuring stronger foundations as well as optimizing the site for landscaping, road construction and structural projects, are revealed by going beyond the usual passes.

The sheepsfoot compaction techniques advanced professionals are looking for; Firstly, one has to incorporate precision timing, moisture control, lift handling, and instrumented feedback all at once to achieve better results. Weaving theory and practice together, let’s explore these methods one by one.

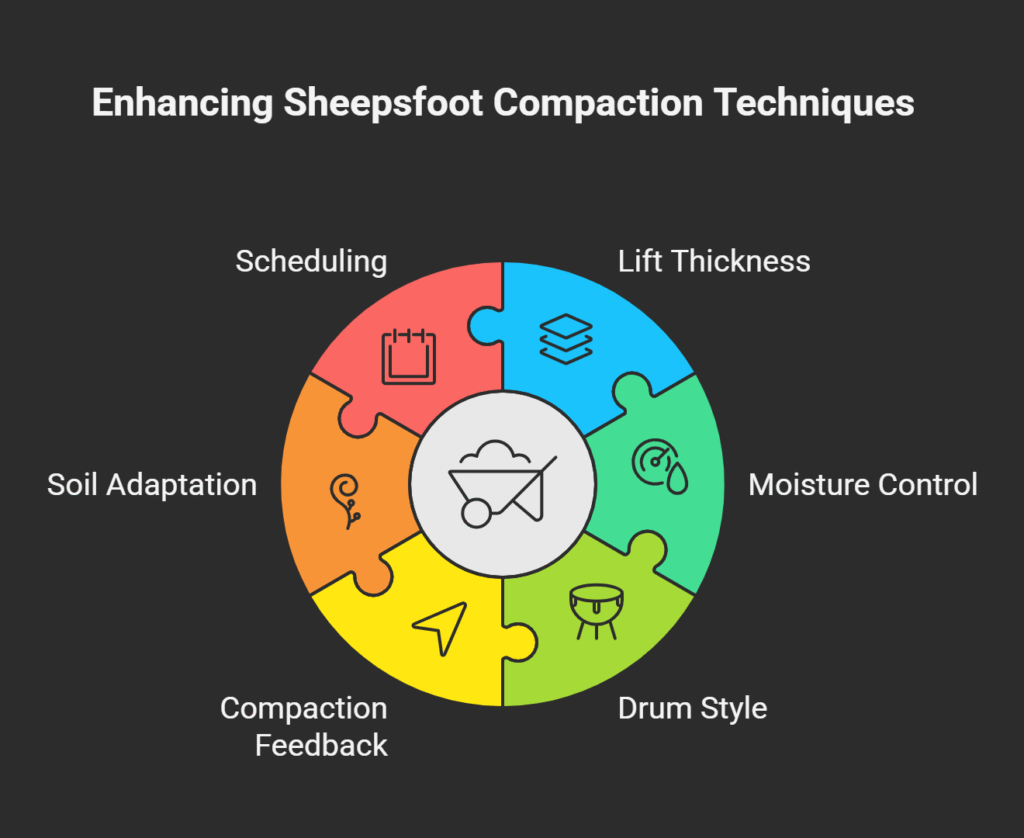

Top Methods for Sheepsfoot Compaction:

-

Precision Lift Staging & Pass Sequencing

Soil lifts that are precision staged and pass sequencing that is well thought out will clay-type soil to be compressed to their inner side thus ensuring uniformity of compaction thereby making it less likely to revert back i.e. to be effective especially in cohesive soils like clay and silt.

Thin lifts that are controlled: Penetration by the sheepsfoot’s feet can therefore be totally effective so staging soil in 6-8 in (150-200 mm) lifts not only assures full penetration by the sheepsfoot’s feet, but also bottom-up consolidation is optimized.

Nodding layer-by-layer: While the layer under each pass is being kneaded and tightened, the top disturbed- this is by design: from the bottom up compaction gets better.

Strategic pass coverage: Start by making the straight passes overlap, then after that run alternate diagonal rolls so as to accomplish an even density throughout the layer.

With this technique stable, high‑density substructures are obtained and at the same time, each soil particle is provided with its share of oxygen.

-

Moisture Management & Timing

Moisture, alongside the integration of the air and water into compaction, is a subtle but essential factor for the advanced sheepsfoot techniques. The following steps can be taken to achieve the desired results:

Target optimum moisture content: Carrying out Proctor testing (Standard or Modified) will help in determining the ideal moisture level before compaction.

Damp-but-not-wet application: For clay, the soil should not be overly moist, as an overwatering will cause slippage and long-term settlement, while if the soil is under-watered, the compaction will be inefficient.

Timing passes strategically: In expansive soils, compact mid-morning when moisture is balanced—not too wet from dew nor dried out by the sun. Farmers and field professionals often recommend rolling just after a slight dry-in period rather than continuous wet compaction.

-

Tool Modifications & Drum Design Choices

One of the main aspects that affect on-site modifications and sheepsfoot compaction results is the choosing of the correct sheepsfoot design and making on-site modifications.

Peg vs. pad styles: Compared to “pegs” (round spikes), which deeply penetrate and compact, rectangular or oval pad-style foot might better perform when sealing and completing surface compaction is the priority.

Custom weight adjustments: If you want to increase the effective load, which will lead to the improvement of compaction, you may decide to add ballast (like calcium or water ballast) to double the heavy side of your machine. Nevertheless, you should always make sure that you are not exposing your equipment to corrosion or over‑weighting.

Drum spacing and overlap: Adjust roller paths so footprints overlap evenly to eliminate weak zones and promote uniform density.

-

Monitoring & Feedback for Quality Control

Advanced compaction is not taking chances with luck—it takes in measurement and feedback:

Leverage density tests: Employ sand cone, balloon densometer, or nuclear density gauges to verify in-situ density against Proctor lab values.(GX Contractor, STGEC)

Moisture sensors and gyro mapping: Field-grade sensors and GPS mapping monitor the compaction process across the lifts—uncovering by under-compacted areas in real time.

Visual and physical cues: A sheepsfoot rides smoothly when compaction is complete; rutted or bouncy response signals that further rolling is needed.

-

Soil Type Adjustments & Hybrid Techniques

The cohesive soils that are not all the same – adjust your methods accordingly:

Clay vs. silt behavior: Clay requires more kneading and passes while silt can compact faster but still be good for the sheepsfoot’s deep pressure.

Gyro or vibratory hybrids: On mixed (clay-silt blends) combining static sheepsfoot passes and vibratory tamping obtains the best densification of the soil.

Post‑compaction moisture control: After rolling, let it dry slowly and then do light grading to prepare for the part used for landscaping or the final layer.

-

Advanced Scheduling & Productivity Tactics

Managing to combine both productivity and effectiveness require you to become both a planner and a flexible person:

Staggered rolling schedules: Allow passes followed by drying windows—this speeds up project flow while ensuring quality.

Dual-crew coordination: One crew preps lifts and moisture, another rotates roller passes—reducing idle time.

Temperature-aware operations: In cooler weather, compaction may take longer—plan for more vibration or additional passes.

-

Snapshot Table: Traditional vs. Advanced Sheepsfoot

| Technique Aspect | Traditional Approach | Advanced Technique |

| Lift Thickness | 8–10 in standard | 6–8 in controlled for better penetration |

| Moisture Control | General field moisture | Based on Proctor’s optimum moisture (ASTM tests) |

| Drum Style | Standard peg feet | Custom peg/pad mix, weighted ballast, spacing optimized |

| Compaction Feedback | Visual/radar judgment | In-situ density tests, moisture sensors, GPS mapping |

| Soil Adaptation | One-size for all soils | Tailored clay vs. silt strategies, vibratory hybrids |

| Scheduling | Continuous rolling | Staggered cycles with drying and alternating crews |

FAQs On Sheepsfoot Compaction:

What is the ideal lift thickness for advanced sheepsfoot compaction?

Typically, 6-8 inches (150-200 mm) are used for complete depth penetration and optimal densification.

What is the best method to find the right moisture level for the sheepsfoot rollers?

In order to find the optimum moisture content for your soil, use Standard or Modified Proctor tests (ASTM D698 or D1557) to achieve this goal.

Is it better to use peg‑style or pad‑style feet for compaction?

While peg feet give a deeper cutting for the cohesive parts of the soil, pad feet are more suitable for the sealing of surfaces. It is possible to get the most out of your compaction by using both types in combination depending on your process stage.

How would I know that the process of compaction is complete?

As a sheepsfoot moves on a dense layer, it makes a smooth ride. For accuracy, you can use nuclear density, sand-cone tests, or moisture probes to verify the target values.

Is the use of vibration encouraged in sheepsfoot compaction?

Of course, vibratory sheepsfoot rollers or sequenced static plus vibratory passes extend the compaction, more so, in the case of mixed soil types.

Are there any benefits in loading the drum with ballast?

The effectiveness of the compaction can be increased by the rising of the weight (water or calcium) but at the same time, a risk of corrosion and overloading the equipment should be taken into consideration.

In what ways can I take advantage of compaction to go faster as long as I do not sacrifice the quality of the work done?

By employing a variety of passes with drying intervals, proper moisture staging, and the use of dual crews—one prepping layer conditions and the other compacting—the efficiency can be maximized.

A Summary about Sheepsfoot compaction:

Sheepsfoot compaction that goes beyond the basics is a process that requires you to be exact, careful, and very detailed in moisture balancing, lift staging, tool customization, and feedback control.

You will get better density of the soil, long-term stability of the foundation, and will work your project efficiently if you apply advanced techniques as you have done in the past but now you make use of Proctor testing, instrumented measurement, drum adaptation, soil-specific strategies, and optimized scheduling for the same.

For professionals like landscapers, road construction companies, and site developers who visit the https://rollercompactor.net/ website and are willing to incorporate these methods into your compaction operations, it simply means your work output rises with the flow, and you attain your set objectives within stipulated time.