Thinking Through Double Drum Rollers’ Future

In the busy construction industry, where accuracy and efficiency rule, the double drum roller is a hero. Its twin, cylindrical drum flying over roadways, parking lots, and runways, like aggressive dancers, powers runs. Big rollers divide asphalt and dirt into level, consistent layers to provide a sturdy platform that any project starts from. Understanding the value of twin drum rollers in contemporary architecture enhances output and quality of work.

Double-drum roller history is full of advancement and originality. From embarrassing instruments unable to meet the demands of a fast-growing industry, these machines have evolved into sophisticated technical marvels. Technological advancements have revitalized its design, thus boosting operator capabilities and experiences. This evolution might provide construction professionals with any tool to direct their future judgments. Come meet us to learn the history, present, and future of double drum rollers as well as how they progress the construction industry.

Double Drum Rollers: Evolution Throughout History

Double drum rollers began their journey early in the 20th century when construction equipment was under development. Early, simplistic, heavy designs fought to increase construction site efficiency. These early forms looked like large carts with one heavy drum and lacked the force and stability needed for compaction. Operators labored over uneven terrain to operate these machines, creating insufficient paving unable to meet the growing demand in the sector. These fundamental principles laid the road for a building revolution.

Major events shaped double drum rolls throughout millennia. A major development right in middle of the 20th century were twin drums, which permitted simultaneous compression from both sides. This idea raised efficiency and produced uniform asphalt layers throughout paving projects. Development of construction tools rely on double drum rollers because hydrostatic drive systems and vibrating drums become better. Every invention enhanced accuracy and control, which changed the way paving tools were used on building sites.

Modern tools still benefit from these revelations. Ten years ago, twin drum rollers with integrated soil density monitoring and on-demand compaction pressure adjustment were unheard of. These advances demonstrate how each one of the steps advances the basic discoveries of past decades to drive contemporary paving technology. Looking back, double drum rollers have evolved not just as equipment but also as a means of fitting changing construction industry needs.

The Evolution of Double Drum Rollers

The building equipment industry has evolved significantly thanks to innovative technologies in double drum rollers and automation. Not only are modern systems comprising sensors and algorithms optimizing performance, but also power tools. Real-time feedback systems monitor soil conditions and automatically adjust compaction settings in certain current versions. This offers a more constant and reliable surface, therefore reducing the need for future repairs and improving the building efficiency.

Engine performance has changed as manufacturers give fuel efficiency and pollution main priority. By utilization of turbocharging and electronic fuel injection, modern engines provide incredible power with less petroleum used. Hybrid cars’ electric motors and diesel engines assist to lower noise levels and fuel costs. These advances enable environmentally friendly construction techniques that meet the growing awareness of the sector and help to boost the bottom line.

One outstanding example of equipment where safety now takes center stage is double drum rollers. Among operator controls, ergonomic joysticks and touchscreens help to increase accuracy and usability. Modern rollers find workers and dangers using proximity sensors in combination with automatic shut-off mechanisms. These developments dramatically reduce worker accidents, therefore fostering a construction industry safety culture. As these technologies evolve, they will boost production and provide operators and crew members safer working conditions.

Contemporary Construction Using Double Drum Rolls

Double drum rollers are work horses on construction projects when efficiency is very essential. These machines compress efficiently and lower the pass count with their solid construction and twin-drum design. Their level, clean surfaces extend asphalt layer life and enhance road appearance. Double drum rollers provide special roller compactor features that enable operators rapidly change weight distribution and vibration settings, therefore insuring optimal performance tailored to diverse soil conditions as heavy equipment moves toward flexibility and precision.

Evidence of the flexibility of twin drum rolls comes from Florida’s massive I-95 resurfacing. Contractors used creative compaction technique using two drum rollers. This approach permitted quick changes in soil moisture content and density. A highly successful operation reduction project by 20% showed how new rollers may simplify outdated procedures into fast, quality operations.

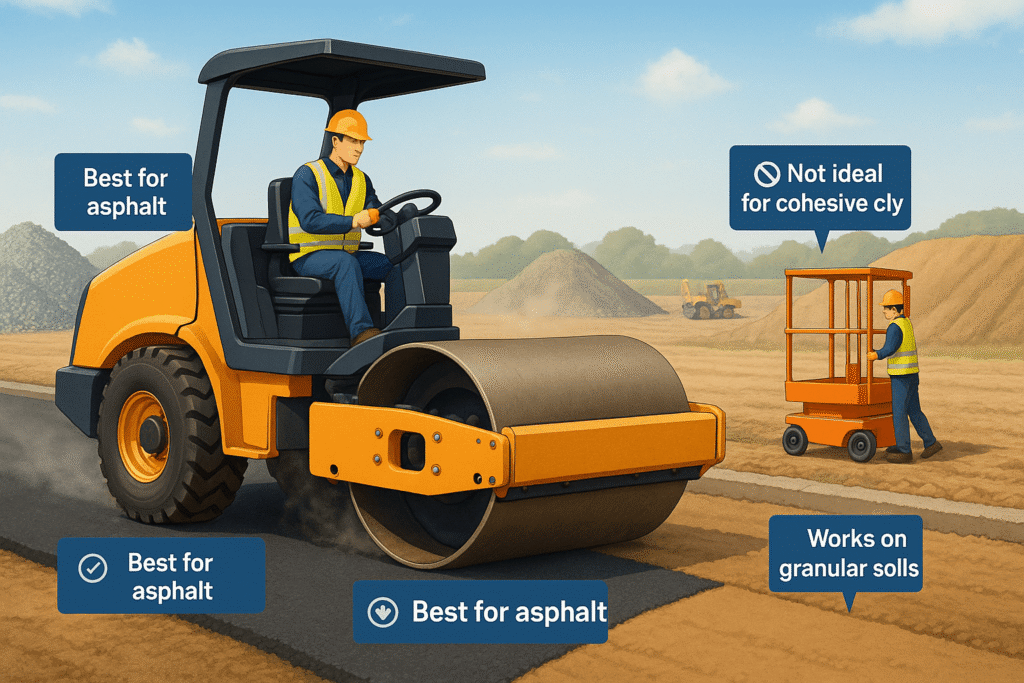

Double drum rollers outperform either static or pneumatic rollers, hence paving relies on them. Static rollers shatter asphalt using weight whereas double drum rollers use vibratory force and mass to provide remarkable density and stability. Pneumatic rollers might be useful even if double drum rollers provide consistent surface compaction. This precision is rather important in urban areas with limited space and the demand of perfect surfaces.

Double drum rolls become notably more crucial as modern builders manage complexity. Among construction equipment, they are special in their ability to provide accurate findings under numerous site conditions. These vehicles provide the means for further developments in heavy equipment as they are the perfect balance of technology and usability in a field that gives speed first priority without compromising quality.

Environmentalism Through Sustainability

Double drum roller production is going toward greener alternatives as the building sector advances. As sustainability becomes increasingly important in modern building methods, manufacturers are changing their designs to lessen their influence on the surroundings. Many companies use unique materials that reduce waste and encourage recyclability, therefore establishing the path for green technology. These developments expose increasing knowledge of the carbon footprint of the building sector as well as creative drive to address it.

Apart from compliance, environmentally friendly products and methods increase operating efficiency. Roller building uses lighter yet stronger composites, which lowers occupational emissions and fuel consumption. lawful, silent, emission-free, electric-powered double drum rollers are gaining popularity in locations with noise and air pollution issues as they are lawful. These environmentally appropriate replacements prove builders’ dedication to performance and environmental preservation, therefore defining them as future leaders in road building.

Legal observance influences architectural design. Manufacturers have to change their goods when governments all over tighten environmental rules and emissions control. Among construction experts, this constrained area encourages responsibility and creativity. Every new model companies bring incorporates elements of performance and environmental compliance to surpass expectations. Modern monitoring systems double drum rollers recorded in real time enable to assess fuel usage and emissions, therefore promoting sustainability.

Double drum roller production aids the construction sector toward environmentalism. Professionals who respect the law and use green technologies will be able to meet present demands and improve the surroundings. Those who want to keep ahead in a society undergoing fast change will find these tools very indispensable.

Double Drum Roller Design: Current Trends

Double drum rollers will experience revolutionary changes that will redefine their possibilities and uses as construction enters an innovative phase. Technical advancements are expected to be particularly in integration of smart technologies and automation. Imagine a double drum roller with sensors evaluating real-time soil compaction and adjusting pressure and vibration to reach optimal performance. Every pass shows perfect engineering as higher degrees of responsiveness improve efficiency and reduce material waste.

The development in machine learning and data analytics will improve double-drum roller operations. By collecting massive amounts of data from building sites, these devices might uncover patterns improving efficiency. A roller might look at the regions it has compacted and adjust its settings for similar tasks. With this predictive ability and early on identification of problems, basic users might grow into strategic decision-makers who can modify their behavior.

The development of autonomous automobiles will also influence construction materials like double drum rollers. Imagine a workplace where autonomous rollers easily interact with one another and with other machinery. This combination reduces human error, thereby raising production and safety standards. Manufacturers including AI-driven navigation systems provide the prospect of autonomous operation. These advances ensure everyday performance and free competent staff for more challenging tasks.

Double-drum roller design will finally combine intelligent systems and contemporary technologies to modify construction procedures. These developments let professionals in the sector anticipate better productivity, safety, and smart building technologies that dynamically match the changing requirements of their projects.

Perfect Double Drum Roller for Your Project

As a chef picks the appropriate knife for a great dish, so should you choose the appropriate double drum roller for your building projects. From a little driveway to a big highway extension, rollers offer certain qualities for every use. Important are surface materials, compaction, and rolling weight. In asphalt application—which calls for delicacy—in granular soil compaction, a larger model might perform better than a smaller one.

A good choice relies on understanding of the many models and their characteristics. Manufacturers also produce vibratory rollers for perfect finishing and high frequency compaction. Whereas a pneumatic-tired roller is flexible on various surfaces, a dual-drum vibratory roller excels in thick materials. Drumming width, amplitude, and steering systems may all greatly affect job performance and results.

Builders of construction tools seldom provide constant support and service. Imagine discovering your roller malfunctioning just before a major deadline; fast technical assistance might either meet or fall short of the deadline. Choose businesses with conveniently available customer assistance. As you work on many projects, a strong guarantee protects your investment against unplanned issues.

Choosing a twin drum roller calls for both technical capacity and pragmatic expertise. You will succeed if you correctly balance many models and manufacturer support with project needs. The right roller assures longevity and quality of work, increases running efficiency, and propels you toward a period when every job produces its finest potential result.

Possibilities for Double Drum Rolls

From simple concepts to strong, precise tools based on fundamental ideas and advanced techniques, double drum rolls have expanded in relevance. Their growth reveals ingenuity, effectiveness, and adaptability—qualities that have made them vital for road building all around. As smart technology and eco-friendly solutions spread, these gadgets become increasingly more important in settings of sustainable construction.

Professionals in constructing have to stay current with new technology redefining double drum roller potential. New features at every phase enhance performance, safety, and usage. Driverless autos and data-driven insights will redefine our building challenges. By improving the efficiency and sustainability of your projects and therefore revolutionizing the industry, learning and using double drum roller technology can help you embrace the future.