Why Roller Compactor Maintenance is Crucial?

One of the most crucial elements of the construction and roadwork industries that an asphalt road repair company cannot do without is a roller compactor maintenance. Thus, the asphalt road repair company can compact soil and gravel and also make the asphalt surface smooth and durable—all these can be done by roller compactors.

Despite this, the functioning and the service life of a problem roller compactor, in particular, is almost entirely made possible by proper maintenance and care. In that regard, a roller compactor that has been neglected will not only result in frequent breakdowns, but it will also increase the running cost and the amount of time that the machine is way from work (waiting for repair).

In that case, you will want to be implementing year-round roller compactor maintenance practices for a roller compactor. To walk the talk, through various seasons, routine inspections, lubricating schedules, repairs, and much more. Will best methods of keeping your roller compactor in top condition all year round be covered by us? We believe it is so true. In other words, you can decide whether these points can still assist you in the peak performance of your machine if you are owning only one device or you are a whole fleet manager.

Significance of Roller Compactor Maintenance:

Underlining the significance of the maintenance practices all through the year for a roller compactor. Safety is ensured when you keep the roller compactor in good condition. As a rule, a lack of maintenance will lead to the equipment breakdown, which in turn will take you to the stages of the project where you won’t be able to continue working. What is more, machines that are well taken care of will lead to safer job sites.

Some of the main reasons to emphasize the maintenance are:

- Extended Equipment Lifespan: Regular servicing allows the parts such as drums, hydraulic systems, and engines to remain in good condition.

- Reduced Downtime: The preventive care will eliminate the unexpected breakdowns that may happen at the crucial stage of construction.

- Optimized Fuel Efficiency: The clean and well-tuned engine will take less fuel and give better performance.

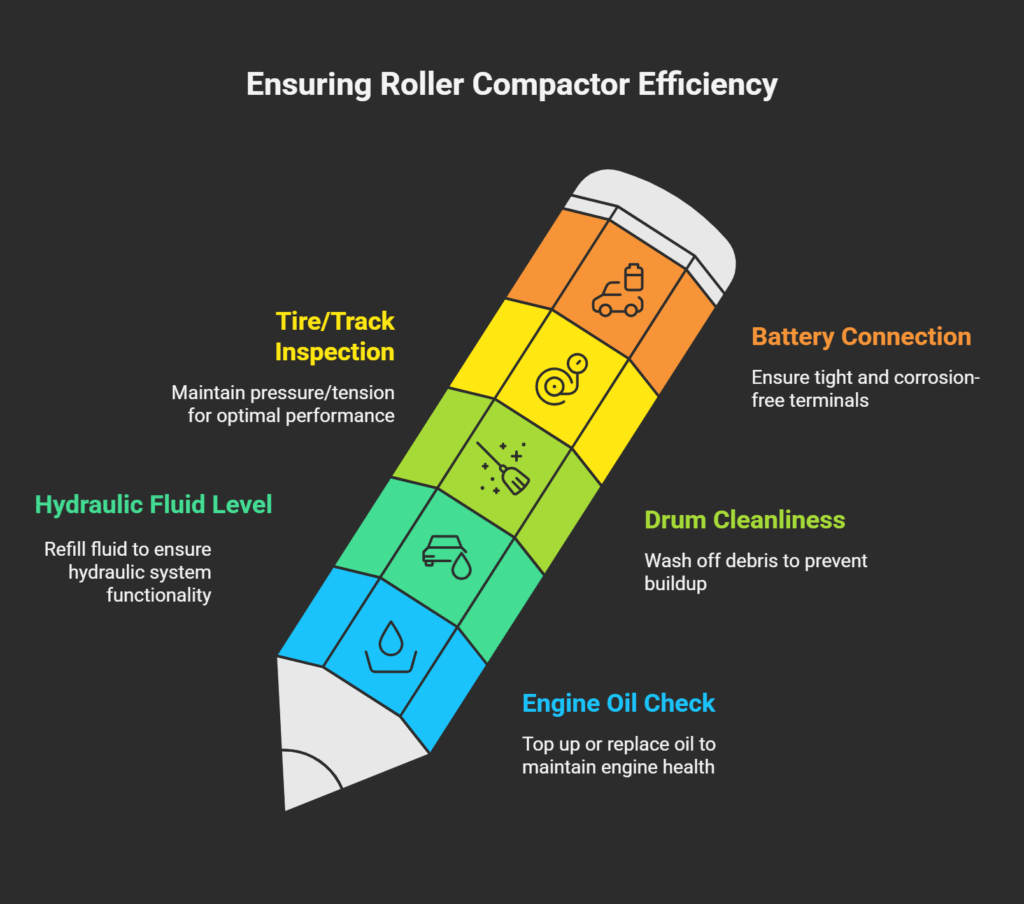

Roller Compactor Maintenance Checklist:

Going through the checkout, daily operations, the staff, should perform a detailed, though very fast, inspection. It basically guarantees that the roller compactor will move smoothly all day long and will also minimize some risks throughout the day.

Below are the main everyday practices:

- Check Fluid Levels: Engine oil, hydraulic fluid, and coolant must be inspected to prevent the occurrence of overheating or hydraulic failure.

- Inspect the Drum Surface: The drum should not have cracks, dents, or be covered with debris that may lower the quality of the compaction.

- Examine Tires and Tracks: Tire pressure is the main thing that needs to be checked daily for pneumatic compactors; for tracked models, the adjustment of tension is the most important.

Daily Roller Compactor Maintenance Table

| Inspection Task | Recommended Action | Frequency |

| Engine Oil Check | Top up if low, replace if dirty | Daily |

| Hydraulic Fluid Level | Check with dipstick and refill if needed | Daily |

| Drum Cleanliness | Wash off asphalt, dirt, or gravel buildup | Daily |

| Tire/Track Inspection | Maintain pressure/tension as per manual | Daily |

| Battery Connection | Ensure terminals are tight and corrosion-free | Daily |

Seasonal Roller Compactor Maintenance Practices

The seasons give different problems to your roller compactor. Results such as the scorching sun, abrupt, dusty winds, heavy rains, and freezing temperatures – they all affect machine performance. A seasonal maintenance plan is a guarantee of being prepared for all climates.

Spring/Summer Maintenance

- To keep overheating out of the question, clean the radiator and the cooling system.

- Check the belts and hoses and change them if they are worn out.

- In the case hot asphalt operations, keep an eye on tire wear.

Fall/Winter Maintenance

- Use winter-grade engine oil and diesel fuel to avoid the situation of fuel and oil thickening.

- Either cover your roller compactor with a protective cover or store it inside.

- Start the machine only after heating it up so as not to affect the engine adversely.

All-Season Tips

- Don’t forget to lubricate all the parts that are in contact and need to be moved.

- The wire that is responsible for the electricity in your machine can be safe from both water and mice by wrapping a sheet of special material around it.

Lubrication and Fluid Management for Roller Compactors Maintenance:

Fluids are the lifeblood of your roller compactor. Without regular lubrication and timely fluid replacement, parts wear out quickly, leading to expensive repairs.

Best practices for fluid management are:

- Engine Oil: Oil should be changed at intervals recommended by the manufacturer, especially after a long project.

- Hydraulic Fluid: The quality of hydraulic fluid should be tested regularly in order to prevent contamination.

- Coolant Check: By keeping the cooling water at the right ratio of water to coolant, overhearing in summer and freezing in winter will be avoided.

Fluid Replacement Schedule Table

| Fluid Type | Replacement Interval | Notes |

| Engine Oil | Every 250–500 hours | Use OEM-recommended oil type |

| Hydraulic Fluid | Every 1000 hours | Check filters every 500 hours |

| Coolant | Annually | Flush system if contaminated |

| Transmission Oil | Every 1000 hours | Replace filters simultaneously |

Even with regular maintenance, roller compactors are prone to certain issues. Identifying them early saves time and cost.

Preventing Common Roller Compactor Problems

- Hydraulic Leaks: Hoses and seals should be inspected for cracks regularly; if they are damaged, they should be replaced at once.

- Uneven Compaction: One should clean the drum regularly and look for uneven wear in it.

- Overheating Engine: Always make sure the radiator is free of debris and the coolant level is at the required level.

Using preventive measures can significantly lower downtime and at the same time, ensure the quality of compaction remains consistent.

Storage and Off-Season Care for Roller Compactors

By properly storing roller compactors, the rust, corrosion, and fluid degradation risks would be kept at bay.

Here is how to store equipment in the off-season properly:

- Clean Completely: Take off old asphalt, grease, and dirt.

- Fuel Draining or Treatment: Put fuel stabilizers or empty the tanks completely.

- Battery Work: Unplug the battery or use a battery charger to recharge.

Storage Checklist:

- Storage at any indoor location or covering with plastic covers.

- Tires are slightly raised to prevent tires from getting flat spots.

- Before long rest lubricating the joints and gears of the machine.

Training Operators on Proper Usage

Even if the roller compactor is in the best condition, it will not take the load successfully without good usage. Training the operator plays a significant role in increasing the efficiency of the machine and safety by the way it is used. Operator training program should at least include the following points:

- Pre-Operation Inspections: The daily checklist operators are to be acquainted with the routine should be given.

- Correct Operation Techniques: Learning of drum vibration, travel speed and compaction sequence is to be done.

- Safety Protocols: Proper PPE, emergency stop instructions and safe maneuvering are the part of safety protocols.

The money that gets spent on training is the best way to avoid the wear and tear of equipment and the lifespan of your roller compactor is thereby extended.

Cost Benefits of Regular Roller Compactor Maintenance

There are some businesses that choose not to have regular maintenance because they think it will save them money. In the long run, this short-term saving will ‘bite them’ back, leading to higher repair expenses and downtime.

Various ways to save money through regular Roller Compactor maintenance:

- Reduced Repair Costs: Avoid overreliance on emergency repairs through routine maintenance.

- Raising Resale Value: Machines that receive proper good maintenance are capable of fetching a higher resale price.

- Functioning Efficiency: By avoiding work stoppages, a company can save on fuel and labor costs making the overall project more profitable.

Comparison Table: Maintenance Costs vs Repairs

| Maintenance Practice | Approx. Cost | Repair Cost if Ignored |

| Oil & Filter Change | $100–$200 | Engine replacement: $5000+ |

| Hydraulic System Check | $200–$400 | Full system repair: $8000+ |

| Drum Cleaning & Alignment | $50–$100 | Drum replacement: $3000–$6000 |

| Tire Pressure Monitoring | $20–$50 | Tire replacement: $1000+ |

Remember the Prominence of Roller Compactor Maintenance:

A roller compactor is basically a fundamental tool that any construction project can do without, but your machine will only be as good as your care for it. Keeping up with preventive maintenance throughout the year guarantees a worry free and cost efficient operation of your unit.

Every procedure from daily inspections to the seasonal changes, planned lubrications, and operator training not only contributes to the prolonging of the life of the roller compactor but also results in its productivity increase. Making maintenance a priority, you not only save time but the costs are also reduced and the safety of the worksite is enhanced.

FAQs on Roller Compactor Maintenance

How often should I change the engine oil in a roller compactor?

Changing oil for every 250–500 working hours is generally recommended by most manufacturers, which is also dependent on the machine and workload.

What is the best way to prevent hydraulic leaks?

Check hoses, seals, and fittings regularly, and if any part is found to be worn out, immediately replace it with a new one. Also, the hydraulic fluid that is contaminated should be replaced.

Can roller compactors operate in cold weather?

Yes, but in that case, the oil of winter-grade should be used, the engine preheated, and the machine kept in a safe place when it is not used.

How do I know if my roller compactor drum needs replacement?

If the drum has deep grooves or cracks, the wear of the drum is uneven, and if compaction inefficiency is observed even after cleaning, it is quite possible that a replacement is needed.

What is the average lifespan of a roller compactor?

A roller compactor that is properly taken care of can be with us for about 10-15 years or more, of course, it also depends on how it is used.

Do I need to clean the roller compactor every day?

Yes, cleaning is the main activity that prevents asphalt, gravel, or debris that has been deposited on the drum from hardening and affecting compaction quality.

What type of fuel should I use in my roller compactor?

Almost every roller compactor is powered by a diesel engine. To make sure the proper working of the machine and to prevent the engine from getting damaged, always follow the manufacturer’s advice and use the recommended grade.

Describe the roller compactor maintenance best practices used during the winter?

Keep using winter-grade oil, perform regular hydraulic system maintenance, and as part of your asphalt roller care, make sure you are warming up the engine before operation.