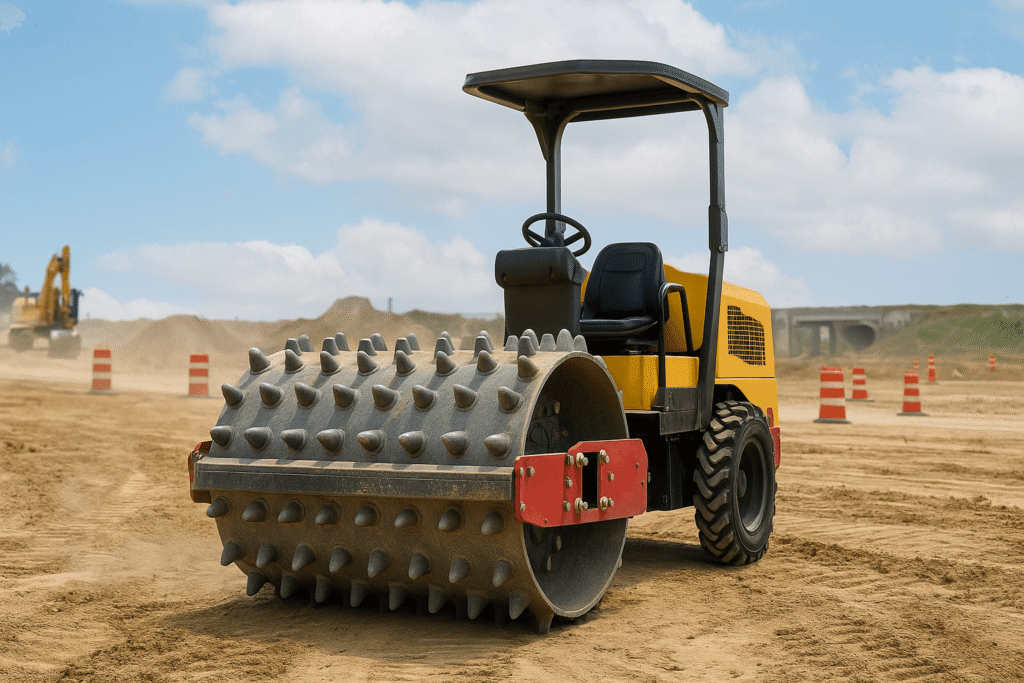

A road roller with spikes is a specialized heavy machinery designed to provide enhanced soil and material compaction by using a drum fitted with protruding metal spikes or pads. This design differentiates it from traditional smooth drum rollers and offers unique benefits for difficult terrain and challenging soil conditions.

Design and Structure

The key feature of a spiked road roller is its drum studded with sturdy spikes made from wear-resistant alloys like hardened steel. These spikes penetrate and disrupt soil clumps during compaction, increasing soil density and stability. The drum assembly is mounted on a robust frame attached to a chassis housing the engine, operator cabin with controls, and axles supporting the tires. The machine is powered by a high-performance engine enabling smooth operation and movement.

How Spikes Enhance Compaction

The spikes focus the roller’s weight into smaller contact points, significantly increasing the pressure exerted on the soil surface. This pressure improvement leads to deeper penetration into compacted materials compared to conventional rollers, breaking up soil particles and reducing air voids. The result is a uniformly compacted, denser, and more stable surface with better load-bearing capacity.

Advantages of Road Rollers with Spikes

-

Improved Soil Penetration: Spikes reduce the drum contact area, amplifying pressure and enabling better penetration for optimal compaction.

-

Enhanced Soil Aggregation: The spikes disrupt and rearrange soil particles, improving density and decreasing settling or shifting over time.

-

Superior Traction: On slippery, uneven, or wet surfaces, spikes grip better, ensuring the roller maintains traction without slipping, which enhances operator control and compaction efficiency.

-

Versatile Applications: Ideal for road construction, landscaping, groundwork, municipal infrastructure, and any construction requiring stable surfaces on challenging soils.

Safety and Operational Features

Modern spiked road rollers come equipped with operator safety features such as emergency shut-offs, seat belts, and protective guards. Controls for vibration, speed, and steering are ergonomically designed for ease of use and precise handling.

Road rollers with spikes are robust compaction machines offering superior performance on difficult terrains and complex soils. Their enhanced penetration ability, improved soil aggregation, and outstanding traction capabilities make them invaluable in construction projects demanding stable, long-lasting surface compaction.

What are the main benefits of using a road roller with spikes

The main benefits of using a road roller with spikes include:

-

Enhanced Soil Penetration: Spikes concentrate the compaction force on smaller points, allowing deeper penetration into soil layers, which improves compaction density and stability.

-

Improved Soil Aggregation: The spikes break up clumps and redistribute soil particles, reducing air voids and increasing load-bearing capacity.

-

Better Traction: Spiked rollers provide superior grip on slippery, uneven, or wet surfaces, enhancing operational control and safety.

-

Efficient Compaction: Fewer passes are needed to achieve desired compaction levels, saving time and fuel costs.

-

Versatility: Suitable for a wide range of applications including road construction, landscaping, municipal projects, and difficult soil conditions.

-

Durability: Spikes are made from hardened, wear-resistant materials ensuring long-lasting performance under tough working conditions.

These benefits make spiked road rollers ideal for achieving strong, stable, and uniform surfaces in challenging construction environments

How do spike rollers compare to traditional smooth-drum road rollers

Spike rollers and traditional smooth-drum road rollers differ primarily in design, compaction mechanism, and ideal applications, with each offering distinct advantages:

Spike Rollers

-

Design: Equipped with metal spikes protruding from the drum surface to penetrate and disrupt soil clumps.

-

Compaction Mechanism: Concentrated pressure at spike tips allows deeper soil penetration and better redistribution of soil particles.

-

Surface Interaction: Spikes increase traction and grip, especially on uneven, slippery, or loose soils.

-

Best Use: Effective on cohesive soils, mixed soil conditions, and challenging terrain where soil disruption and surface grip are critical.

-

Compaction Efficiency: Fewer passes required for effective compaction in tougher soil types.

Traditional Smooth-Drum Rollers

-

Design: Feature smooth, continuous steel drums applying uniform pressure over the surface.

-

Compaction Mechanism: Apply static or vibratory force evenly across the soil or asphalt surface to flatten and densify top layers.

-

Surface Interaction: Provide a smooth finish ideal for paving and asphalt compaction.

-

Best Use: Suitable for granular soils, asphalt paving, and large-scale projects requiring smooth, uniform surfaces.

-

Compaction Efficiency: Highly efficient for surface leveling and compaction across broad, even areas.

Comparison Summary

| Aspect | Spike Rollers | Traditional Smooth-Drum Rollers |

|---|---|---|

| Drum Surface | Studded with metal spikes | Smooth steel drum |

| Soil Penetration | High, due to spike point pressure | Moderate, surface compression |

| Traction & Grip | Superior on uneven/slippery ground | Standard traction |

| Surface Finish | Less smooth, more disruptive | Smooth, even surface |

| Ideal Soil Type | Cohesive, mixed, challenging soils | Granular soils, asphalt |

| Application | Road base, groundwork, landscaping | Asphalt, road surfacing, large areas |

| Passes for Compaction | Fewer on tough soils | Multiple for uniform surface |

In essence, spike rollers are better for penetrating difficult soils and providing traction, while smooth-drum rollers excel in creating smooth, dense surfaces on paving projects. Choosing between them depends on the soil conditions, project requirements, and desired surface finish

What Is a Road Roller with Spikes? Key Features and Benefits

A road roller with spikes is a specialized construction machine designed to compact soil, gravel, or other materials more effectively by using a drum fitted with protruding metal spikes. These spikes focus the roller’s weight on smaller points, allowing deeper penetration into the material compared to traditional smooth drums.

Key Features

-

Spiked Drum: The drum has heavy-duty metal spikes made from wear-resistant alloys like hardened steel, which penetrate soil clumps to break them up and create better material distribution.

-

Efficient Compaction: Spikes increase pressure at point contact, enabling deeper, more uniform compaction with fewer passes.

-

Enhanced Traction: The spikes grip uneven or slippery surfaces, improving stability and preventing slippage during operation.

-

Robust Design: Powered by a high-performance engine with ergonomic controls, including vibration settings and safety features such as emergency shut-offs and protective guards.

Benefits

-

Deeper Soil Penetration: Concentrated pressure from spikes ensures stronger, more stable surfaces ideal for roads, foundations, and landscaping.

-

Improved Soil Aggregation: Breaking up soil clumps and redistributing particles improves density, reduces voids, and increases load-bearing capacity.

-

Versatile Application: Suitable for all-weather roads, dirt paths, landscaping projects, and construction site preparations.

-

Increased Efficiency: Requires fewer passes to achieve desired compaction, saving time and operational costs.

In summary, road rollers with spikes enhance compaction performance and surface stability by combining mechanical penetration with traditional rolling pressure, making them indispensable for challenging construction and groundwork projects.

What are the maintenance requirements for spike road rollers

Maintenance requirements for spike road rollers focus on ensuring the longevity and efficient performance of both the spikes and the machine’s core components. Key maintenance tasks include:

Spike and Drum Maintenance

-

Regular Inspection: Check spikes daily for wear, cracks, or damage. Replace or repair worn or broken spikes promptly to maintain effective compaction.

-

Cleaning: Remove soil, debris, and rust buildup around spikes after use to prevent corrosion and ensure spikes retain their penetrating ability.

-

Lubrication: Apply proper lubrication to moving parts connected to the drum and spike mounting points to avoid seizure or excessive wear.

Engine and Hydraulic System

-

Fluid Checks: Regularly monitor engine oil, hydraulic fluid, coolant, and fuel levels, topping up or changing fluids according to the manufacturer’s schedule.

-

Filter Replacement: Change air, oil, and hydraulic filters periodically to maintain engine health and system cleanliness.

-

System Inspection: Inspect hydraulic hoses, connections, and cylinders for leaks or damage and repair as necessary.

General Structural and Safety Checks

-

Fasteners and Mountings: Tighten bolts, nuts, and clamps on the drum assembly, spikes, and chassis to prevent loosening from vibration.

-

Controls and Safety Equipment: Test the functionality of operator controls, safety shut-offs, seat belts, and other protective features frequently.

-

Tire and Brake Maintenance: Examine tires for wear and proper inflation; check brake systems for responsiveness and wear.

Scheduled Servicing

-

Periodic Overhauls: Conduct comprehensive servicing after specific operating hours (usually every 500-1000 hours), including spike replacement, hydraulic system flush, engine tune-ups, and vibration system inspections if applicable.

-

Preventive Maintenance: Follow the manufacturer’s maintenance manual strictly for scheduled servicing intervals to avoid costly breakdowns and downtime.

Proper and routine maintenance of spike road rollers ensures peak operational efficiency, safety, and prolonged equipment life, essential for demanding construction environments.