Differences Between Plate Compactor and Roller Compactors: The Ultimate Guide for 2026

In the rapidly changing world of construction and landscaping, it is critical to establish a sound foundation to achieve not just any successful project but a sustainable one. It is always a debatable decision among choosing Plate Compactor vs Roller Compactor and It is all about the ground, the underneath, the base, in fact, it is the ground that will last your driveway, building, or road, not the structure.

Therefore, tremendous importance should be given to selecting the most suitable compaction equipment. The decision between Plate Compactor vs Roller Compactor is a frequent one, with each piece of equipment offering particular benefits depending on the size and type of job.

Understanding Plate Compactor vs Roller Compactor

Gaining a quick understanding of the differences and similarities of these two powerful tools is bound to lead to significant savings in time, money, and maintenance in the long run.

Compaction involves the densification of construction materials, mainly soil or asphalt by air evacuation. This mechanical densification not only helps to prevent structural damages like sinking or collapse but also acts as an insulation layer and limits water infiltration.

The two machines help achieve the same end result—a dense, stable base—but differ as to how they go about it and are intended for different sizes of jobs. Walk-behind plate compactors are generally small-sized machines that emit high-frequency vibrations to help particles settle and thus are perfect for granular soils and for work in small spaces.

Meanwhile, a roller compactor is a large, often ride-on machine that uses heavy weight and lower-frequency, high-amplitude vibrations to break and compact soil or asphalt layers deeply and over large areas.

- Mechanism of Action: Plate compactors generate rapid vibrations to transport soil particles, whereas rollers apply heavy static weight and shear force.

- Scale of Operation: Plate compactors are precision tools for small spots, and rollers are fast and efficient in vast spaces.

- Operator Control: Plate compactors are manually guided (walk-behind); rollers are ride-on or remote control.

In depth: What is a Plate Compactor?

Plate compactor (vibratory plate) is the most domestic tool for leveling small surfaces. At the bottom of the machine head, there is a heavy steel plate, which is powered by a gasoline or diesel engine.

The engine operates an eccentric weight mechanism, which creates rapid vibrations. The vibrations are carried by the plate from the machine to the ground where the soil particles are made, so to speak, to dance, and as a result, they get closer to each other.

This way the air voids are squeezed outside. This method of compaction is extremely well-suited for granular soil such as sand and gravel. Here the soil particles need to be “jammed” tightly together through movement.

One of the most attractive features of this machine is its maneuverability. Since the tool is relatively small and light, it can be easily transported in the back of a truck and moved around a building site with one or two people. This makes it indispensable for landscaping, trench working, and paving. But due to the smaller weight, the depth of compaction cannot be extensive.

The process normally affects only the top few inches of the soil, so if the depth of the filling is more, then the compacting should be done in thin layers or “lifts” to keep the base stable throughout.

- Perfect Job Scenarios: compacting sub-base for a driveway, sidewalks, and patio; compacting trenches for utility lines; setting paving stones.

- Type of Soil: Best suited for granular soils (sand, gravel) and asphalt patching; however, not too effective on clay soil.

- Highlight: outstanding maneuverability facilitates operation in limited spaces, at corners, and up to vertical walls or curbs.

In depth: What is a Roller Compactor?

Roller compactors play the role of heavyweights in the game of soil compaction, and the performance of such machines is typically measured against their ability to deal with large-scale infrastructure projects.

Walk-behind single-drum, double-drum, or pneumatic tire ride-on rollers are some of the machines available. A roller compactor is mainly a huge piece of steel exercising a lot of weight onto the ground, combined with a vibratory force. The steel drum of high mass compresses soil or asphalt from the top through a great force.

Moreover, the internal vibratory mechanism sends shockwaves deep into the ground to organize soil particles at a much greater depth than a plate compactor can reach.

Roller compactors today are equipped with the latest technology so as to get their output to the max. A number of features like articulated steering, water sprinkler systems for asphalt work, variable vibration settings to adapt to different soil conditions are some mentioned on rollercompactor.net.

Their large weight allows rollers to compact cohesive soils, like clay and silt, much more effectively than plate compactors. When you are after making a highway, parking lot, or industrial foundation over acres of land, a roller compactor is practically the only piece you can trust to reach the required densities of the soil within a reasonable timeframe and with a reasonable amount of effort.

- Perfect Job Scenarios: resurfacing and construction of roads; parking lots and industrial yards; foundations of buildings and large earthworks.

- Type of Soil: capable of handling both granular and cohesive soils efficiently (clay, silt), besides being able to finish asphalt surfaces.

- Edge: super-fast rollers vastly increase the area covered per unit of time and thus, by using fewer passes, are able to achieve greater depth of compaction.

Dissecting: Performance and Efficiency

Performance is most of the time the decisive factor in advantages and shortcomings in the case of Plate Compactor vs Roller Compactor. The roller compactor far outstrips the plate compactor in terms of the amount of area covered and the speed of work. A ride-on roller can easily do an 80-inch wide path in one go, and it can even go a few miles per hour in terms of speed.

Compared to that, a plate compactor can only manage a width of 15 to 25 inches and at a pace of a slow walk. Thus if the project size is in the range of thousands of square feet, a roller can only take a few hours whereas a plate compactor, in the best of cases, can take days.

Contrarily, in terms of “performance” you’re not only talking about the aspect of speed, but also the quality of the finish as well as the very specific site needs. Large rollers may have difficulties in turned corners or running along the edges of irregularly shaped areas.

This is when the exceptional compatibility of the small plate compactor becomes much more noticeable. The small compactor can even get to those areas hardly accessible by big rollers such as corners, footing walls, or manholes, trees, etc.

- Compaction Depth: Rollers can easily handle 12 inches or even more of compacted layers, whereas plate compactor is limited to 4-6 inches.

- Surface Finish: Rollers provide smooth, flat surfaces which are essential for asphalt roads; plate compactors can leave little ridges or here and there an unevenness if the operator didn’t adequately do it.

- Transportation: Rollers need a heavy-duty trailer and a towing vehicle; plate compactors can just be loaded up in a normal truck.

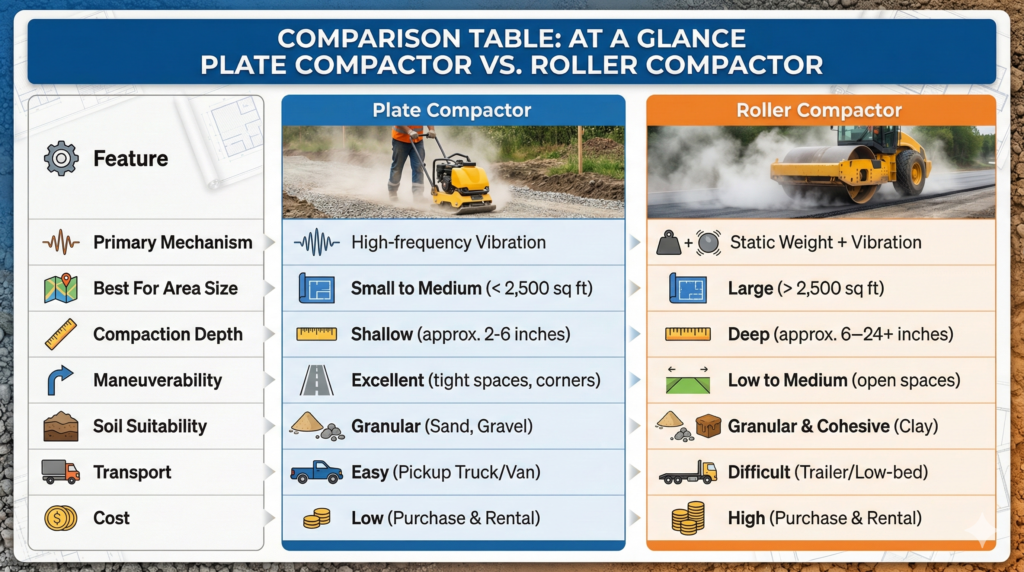

Comparison Table: At a Glance Plate Compactor Vs. Roller Compactor

| Feature | Plate Compactor | Roller Compactor |

| Primary Mechanism | High-frequency Vibration | Static Weight + Vibration |

| Best For Area Size | Small to Medium (< 2,500 sq ft) | Large (> 2,500 sq ft) |

| Compaction Depth | Shallow (approx. 2-6 inches) | Deep (approx. 6-24+ inches) |

| Maneuverability | Excellent (tight spaces, corners) | Low to Medium (open spaces) |

| Soil Suitability | Granular (Sand, Gravel) | Granular & Cohesive (Clay) |

| Transport | Easy (Pickup Truck/Van) | Difficult (Trailer/Low-bed) |

| Cost | Low (Purchase & Rental) | High (Purchase & Rental) |

Cost Implications and ROI

Budget is always a major constraint in construction projects. A plate compactor is significantly less expensive than a roller compactor and that’s both in terms of purchase and rental.

One can expect to pay somewhere between $1,000 and $3,000 for a top-notch professional plate compactor, while a ride-on roller compactor, depending on the size and technology, can start from $15,000 and go to over $100,000.

Purchasing a roller is seldom a financially prudent option for small contractors or home owners unless such entities are engaged in a road work or a large commercial paving projects as a main activity. The rental market bears testimony to the above statement as well since the daily rental rates for rollers are greatly dissimilar from those for plate compactors.

One should, however, bear in mind that the Return on Investment (ROI) is to be based on the factor of productivity. Using a plate compactor on a large site for the purpose of saving on rental costs turns out to be an impractical saving.

The labor hours to compact a large area with a small machine are almost always going to be more expensive than the cost of renting the roller that can do the same job considerably faster.

On the other hand, renting a large roller to do a small patio job is basically throwing money away because such a machine may not even fit in the work area, thus being totally useless. The main goal for the financial efficiency is to correctly evaluate the needed size of the machine.

- First Purchase: The low entry barrier for plate compactors, while the capital investment required for rollers is quite high.

- Running Cost: Rollers burn more fuel and require more expensive maintenance (hydraulics, tires/tracks) than the simpler mechanical systems of plate compactors.

- Labor Savings: On large jobs, a roller reduces labor costs dramatically by completing the work faster with fewer operators.

Safety and Operational Considerations

The foremost factor in the operation of a heavy machine is safety. Each of these two types of machines has its own difficulty and risk factors. Less powerful devices such as plate compactors can be significant contributors to the vibration of the hand-and-arm parts of the operator’s body.

It is therefore necessary to take short breaks or use anti-vibration gloves if you want to avoid the white finger syndrome or nerve damages, among other conditions. They also pose that kind of risk when the operator loses control and the machine runs over his/her feet. Among other safety measures, welding steel-toed work shoes and hearing protection seems a must for the operator.

Roller compactors bring in their size and the momentum as major risks. The major concern among the risks would be rollover accidents especially if the work is done on embankments or generally uneven terrain. Modern rollers come standard with roll-over protective structures (ROPS) and seat belts, which must be used at all times.

Also, since there is limited visibility it is suggested that the operator stays aware of all people and objects in the working area. Additionally, a roller weighs so much that it is capable of breaking underground utilities if they are not sufficiently buried or if the vibration setting is too high.

- Operator Fatigue: Plate compactors require much manual effort; ride-on rollers relieve the operator physically but demand high concentration levels.

- Site Safety: Rollers need ground workers to be within a safe zone and secured, plate compactor demand being careful on foot placement and stable footing.

- Training: Due to the intricacy and hazards posed by the machine, formal training and certification requirements are higher for roller operators.

FAQs – Plate Compactor and Roller Compactors

Which is better, a plate compactor or a roller compactor?

Which equipment is “better” depends entirely on your project needs. If the job is to be done in a small, constrained area like a patio or trench and if the soil is granular, then the plate compactor is the right choice. On the other hand, a roller compactor would be the tool of choice for a large, open area like a driveway or road and when the soil is cohesive for reasons not only of greater compaction depth but also of higher efficiency.

Can I use a plate compactor on clay soil?

That is not really feasible. A plate compactor is well suited for the granular soil like sand and gravel. On clay soil, however, it simply floats or sticks in the sticky ground instead of compacting it. For clay, juveniles of a roller and a rammer would be the right choice.

Do I need a license to operate a roller compactor?

In case you are doing a private project on a private ground, you usually don’t need to have a special license to operate a compactor. Nevertheless, the compliance with safety policies requires that the operator of a construction machine, in general, and a road machinery, in particular, hold a valid construction equipment operator card or certification (like OSHA in the US or CPCS in the UK). Such worksites are road construction and commercial construction projects.

How deep can a plate compactor compact?

A typical plate compactor can improve the compaction of soil largely up to its 4-6 inches (10-15 cm) depth. The heavy-duty reversible plate may extend the reach up to 12 inches but to achieve a homogenous density the best way is to compact always in thin layers.

Why is my plate compactor not moving forward?

Frequently, the cause may be found in a loose or ruptured drive belt, insufficient engine rotation speed, or dirt/debris buildup in the vibrator housing. In addition, the machine may get stuck if the attempted compaction is done on too wet or sticky soil, which causes the plate to be vacuumed to the ground.

How much does it cost to rent a roller compactor vs a plate compactor?

Depending on the place, the rental price may vary. On, average, the daily rental price of a plate compactor is about $60-$100. You can expect to pay much more for a ride-on roller compactor; the usual prices range from $250 to $500+ a day, plus one has to consider additional cost of delivery.

Should I wet the dirt before compacting?

The answer is yes. Moisture plays a major role in compaction. It acts as a lubricant which makes the clay, silt, and sand particles slide along each other and lock into place. Still, over-watering is to be avoided as the soil must be wet enough to form a ball when you squeeze it, but not so wet that it becomes like mud.

Conclusion: Making the Right Choice – Plate Compactor and Roller Compactors

Figure out the right choice between Plate Compactor vs Roller Compactor by carefully analyzing your project needs. For instance, if you deal with a large area, a road is in the making, or structural fills of a considerable depth that require uniform, deep compaction, then the roller compactor will be your trusted king of the job site.

On the other hand, if your project is about residential paving, hardscaping, or utility trenching, the plate compactor will be your hero. Not only is it light and versatile, but it works where large rollers cannot reach.

If a construction company is serious about their compaction work, then they are most likely to keep a roll of both equipment types. By having a range of rollers and plates at the ready, one can always expect a high-quality compaction—from the broad sub-base to the tightest corner of the project.

Knowing the machine, both its capabilities and limitations, will definitely help to get your construction projects stand in the best of conditions for years to come. Get more information on compaction equipment for your work at rollercompactor.net

- Determine the Project Scope: measurements under 2,500 sq ft usually indicate a plate; measurements over indicate a roller.

- Identify the Soil Material: Have you got sand/gravel (plate or roller), or clay (roller/rammer)?

- Consider the Finances: Of course, through rental, transportation, and labor time, you can find the real most cost-effective alternative.