Level Up Your Landscaping Game: Find the Perfect Roller Compactor for Roadwork Today!

Deciding on the best roller compactor for roadwork or landscaping is a choice that will affect your projects in terms of quality, speed, and long-term results. The correct compacting of the soil, gravel, or asphalt is carried out by the compactor itself so that you can be sure to get a smooth and level surface, diminish the probability of the coming repair works.

Let’s Dive into all The Reasons on Choosing Roller Compactor for Roadwork

There are different types of roller compactor for roadwork which include vibratory drum rollers and walk-behind models in the market and one should always bear in mind what is suitable for their jobsite according to the specs. A copy of the details will be provided in the following sections of the text.

In the process of explaining to the user how to select the best compaction equipment, this guide will primarily dwell on the description of every existing type of roller compactors, narrate scenarios where it can be used, and identify the features which should be kept in view at the time of procuring it.

The section is a guide that will lay the way for the user to better comprehend the variety of roller compactors available, decide on one from which the work will be obtained and get to see which innovations are present in this kind of machinery.

Understanding the Different Types of Roller Compactors

Before you select the compactor, you need to be aware of the main categories of the same. Each of these types, with different designs, can be used for a variety of compaction tasks, from repairing a road on a larger scale to small landscaping jobs.

- Single Drum Rollers: These are the best rollers for plain ground and for the compaction of asphalts, especially on large roadways.

- Double Drum Rollers: They have the drums both front and back, made up of steel, for maximum coverage and compaction efficiency.

- Pneumatic Rollers (Rubber-Tired Rollers): They are used for both asphalt sealing and finishing touches as they are flexible and have a kneading effect.

- Walk-Behind Rollers: Perfect for minute, or less spacious areas, usually applications include gardening or spot patching.

Benefits of Understanding types of Roller Compactors:

- Helps you to select the most suitable roller that fits in your project scope.

- Prevents over- or under-compaction issues.

- Enhances operator safety and operational efficiency.

- Results in reducing long-term repair or rework costs.

Factors to Consider When Choosing the Roller Compactor for Roadwork

Choosing the roller compactor that meets your requirements, you need to consider and evaluate a list of key factors that will directly affect the combination of soil and thus the project outcomes. These are the points you should take into account:

- Type of Material: Is it soil, gravel, asphalt, or clay? You need to know that different materials have different compaction requirements.

- Project Size: Large roads and small landscaping paths need different compactor sizes.

- Site Accessibility: We might use walk-behind models instead of large drum rollers where the workplace is not easily accessible.

- Desired Compaction Depth: Vibratory rollers usually provide deeper compaction than static rollers.

Why These Factors Matter:

- Optimizing a roller to the particular soil or material it is being used in.

- Using fewer passes cuts back on fuel and labor consumption, thus reduces emission.

- Helps you decide whether to use manual, skid steer, or ride-on rollers.

- Comes up with a more elegant surface and guarantees durability as well.

Comparing Roller Compactor Specifications and Features

When you’re ready to buy a roller compactor for roadwork, looking at the specs might help you choose between several types. Here’s a short look at the most important specs:

| Feature | Single Drum Roller | Double Drum Roller | Walk-Behind Roller | Pneumatic Roller |

| Weight | 3-12 tons | 3-15 tons | 500–1,500 lbs | 5-30 tons |

| Compaction Force | Medium | High | Low to Medium | Medium |

| Maneuverability | Moderate | Low | High | Medium |

| Best Use | Soil, gravel | Asphalt, paving | Landscaping, patch | Asphalt finishing |

| Price Range | $$ | $$$ | $ | $$$ |

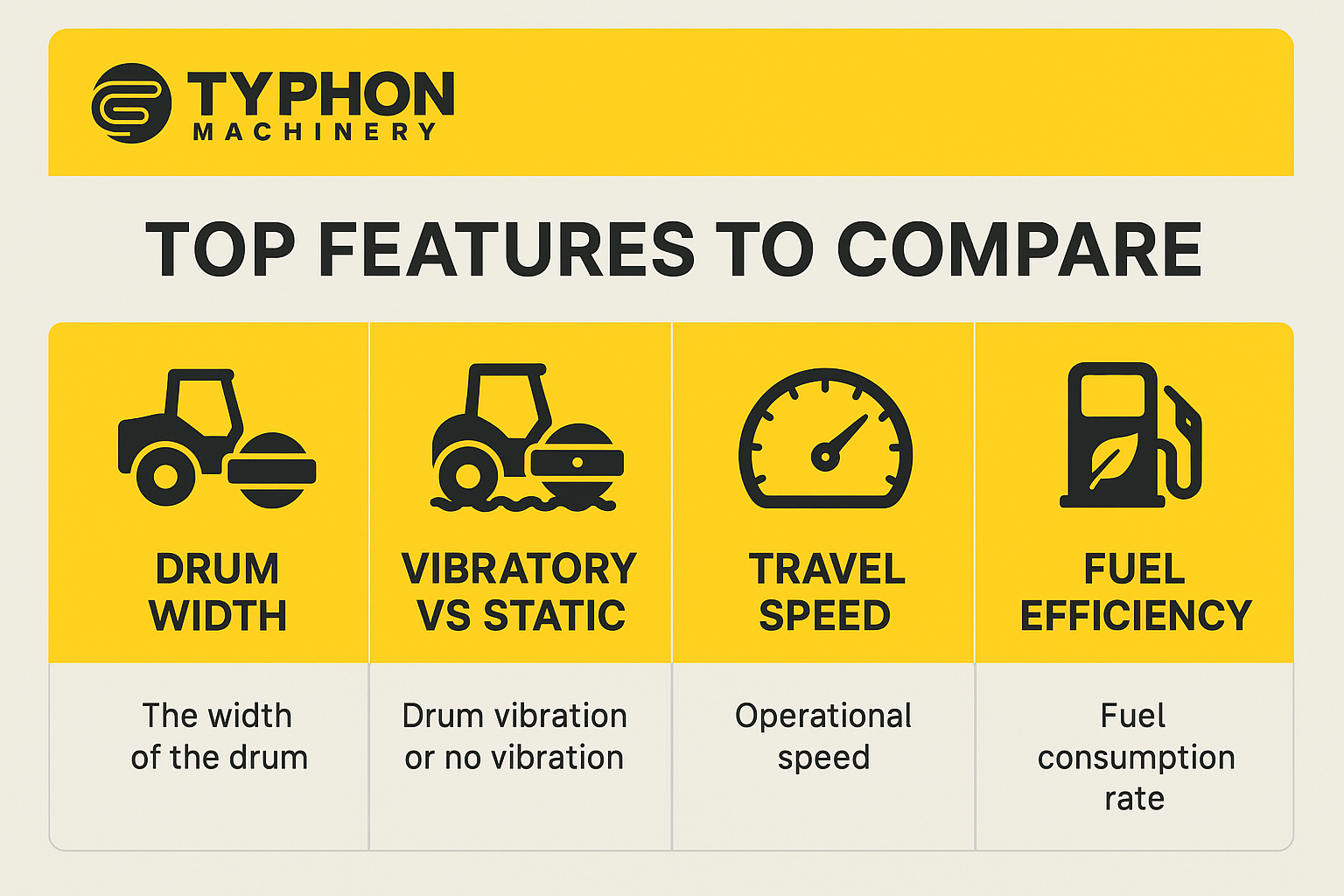

Top Features to Compare:

- Drum Width – Identifies the area of compaction.

- Vibratory vs Static – Vibratory drums make compacting cohesive soils easier.

- Travel Speed – On big areas, quicker travel speed will raise productivity.

- Fuel Efficiency – Lower costs for operation in the future.

Landscaping Roller Compactor vs Roadwork: Which Compactor Fits Best?

Different roller compactors are made for different kinds of labor. Picking one depends on whether you’re doing road work or landscaping makes a big difference.

For Landscaping:

- Lightweight walk-behind or ride-on rollers.

- Better maneuverability in tight spaces.

- Suitable for compacting soil, turf or gravel paths.

- Often used with skid steers using vibratory roller attachments.

For Roadwork:

- Heavy-duty vibratory or double drum rollers.

- Larger drum sizes for wide coverage.

- Enhanced force and depth of compaction for sub-base and asphalt.

- Requires trained operators for proper handling.

Why Project Type Matters:

- Ensures the proper usage of machines for soft landscaping.

- Confirms compliance of the compaction layer with the road regulation standards.

- Influences budget – It is more economical to use smaller compactors for landscaping.

- Reduces the project execution period through the choice of fitted equipment.

Roller Compactor Maintenance and Durability Considerations

To sustain it in its best form, maintenance is vital for the performance of the roller compactor. If the machine is neglected, it is likely to fail in the premature stages and may directly affect the compaction quality too.

- Daily Pre-Checks – Inspect hydraulic fluids, tire/drum wear, and vibrations.

- Scheduled Servicing – Follow the original equipment manufacturer (OEM) recommendations for engine oil changes and part replacements.

- Cleaning – Remove the accumulated soil or asphalt to prevent the drum from getting into build-up situation.

- Greasing and Lubrication – Ensure that all the moving parts work very smoothly.

Why Maintenance is Crucial:

- Increases the equipment’s lifespan.

- Prevents sudden job-site failures.

- Reduces long-term repair costs.

- Maintains consistent results in terms of compaction in the course of several projects.

Price vs Performance: Finding the Sweet Spot

It is attractive to get the most inexpensive or the largest roller but this is not a guarantee that you will harvest the best outcome. Rather, concentrate on the performance per dollar factor by carrying out an ROI assessment over time.

- Buy What You Need – Don’t waste your budget on features that you don’t necessarily need.

- Consider Used Equipment – Fully tested, used rollers can make you save money and at the same time, the performance is not affected.

- Review Warranty and Support – You have to make sure that part availability, and service coverage are in place.

- Match to Project Pipeline – The intensity of the compactor’s usage should be the basis of the purchase.

Smart Buying Decisions Lead To:

- Reduced idle time of machines.

- Greater financial efficiency over multiple projects.

- Lower depreciation costs.

- More flexibility in bidding for different project types.

Its Your Decision to Choose The Right Roller Compactor for Rodwork

Choosing the best road roller or the best land roller is more a matter of grasping the specifics of your material type, the working conditions, the scope of the project, and the long-term equipment demand. Both a road contractor and a landscape designer are advised to match the machine’s technology with their project’s specifics, such as material type and site conditions, to ensure efficient compaction, better and cheaper results.

In case you are in a budget but looking for a multi-purpose machine, do not forget to see vibratory roller attachments for your skid steer too. By following the instruction contained in this guide, you will be quick to make a decision and improve your workflow like a professional.

Frequently Asked Questions Regarding Compactors

1. A vibratory roller and a static roller, what is the distinction?

The differential feature of a vibratory roller lies in the vibration which transmits the compaction energy further down and deeply into the subsurface, notably effective for the non-cohesive soil. In opposition, the static roller’s function is restricted to the uppermost layer of the road, where it is performing the compaction.

2. Should I rent or buy a roller compactor?

If your usage is infrequent then you should rent because it will be cheaper. However, buying is worthwhile if one will be using the compactor often and for a long period of time.

3. What roller attachment fits a skid steer?

Vibratory roller attachments with standard quick-connect plates are compatible with most skid steers. Ensure, however, that the hydraulic system is compatible with the requirements of the attachment.

4. How can I ensure proper compaction?

You can ensure that you follow a rolling pattern, regulate moisture content, and use an appropriate compactor to match the type and depth of the material.

5. What’s the average lifespan of a roller compactor?

By performing regular maintenance, the machine can work for eight to fifteen years. The period of service may vary due to intensity and environmental factors.