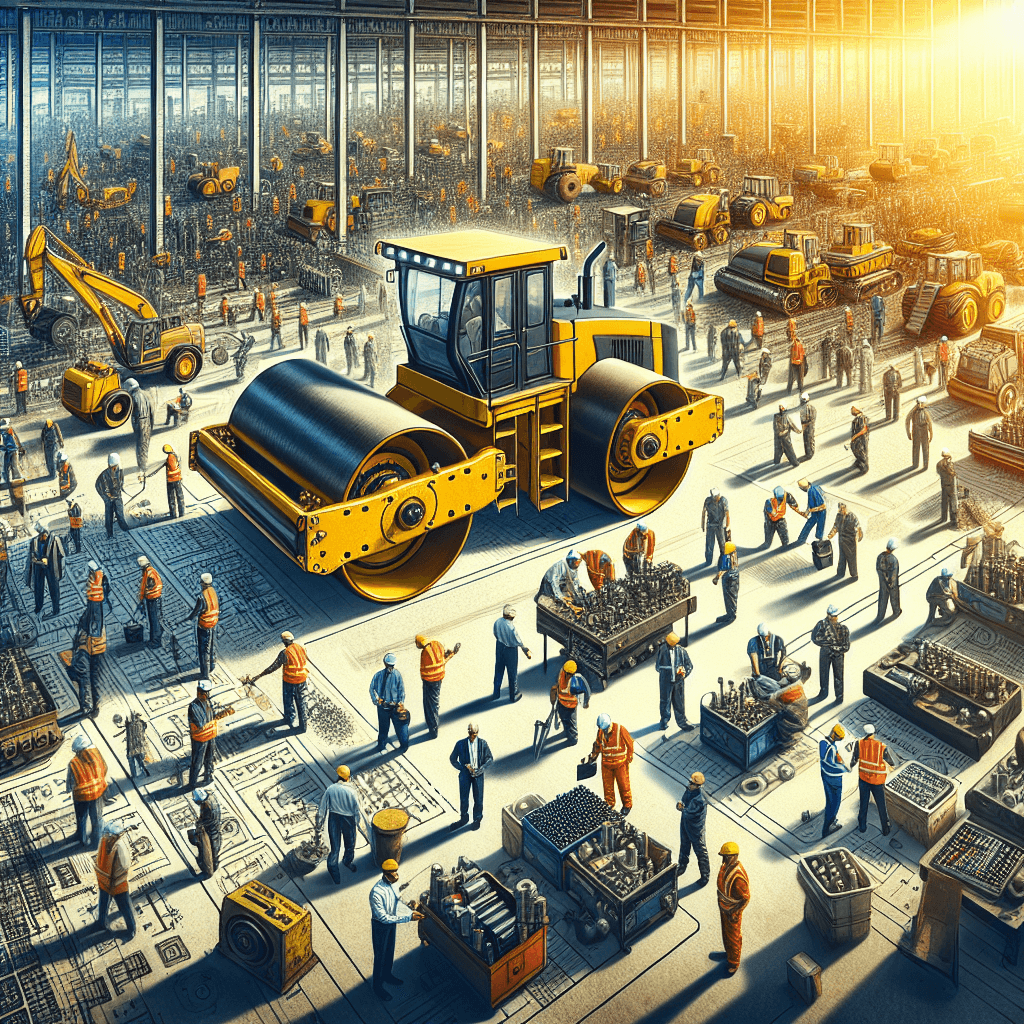

Roller compactors are essential equipment in the construction industry, used for compacting soil, gravel, asphalt, and concrete. These heavy machines are powered by diesel engines and are known for their high fuel consumption. However, advancements in technology have led to the development of more fuel-efficient roller compactors, which not only reduce operating costs but also have a positive impact on the environment. In this article, we will explore the fuel efficiency of roller compactors and the associated maintenance costs.

Fuel Efficiency

Fuel efficiency is a critical factor to consider when choosing a roller compactor for a construction project. Traditional roller compactors are notorious for their high fuel consumption, which can significantly impact the overall operating costs. However, modern roller compactors are equipped with advanced engine technologies, such as electronic fuel injection and variable speed engines, that improve fuel efficiency. These advancements allow the machines to deliver the required compaction performance while consuming less fuel, resulting in cost savings for construction companies.

Factors Affecting Fuel Efficiency

Several factors contribute to the fuel efficiency of roller compactors. The type and quality of the engine play a crucial role in determining fuel consumption. High-performance engines with advanced fuel management systems are more efficient and economical in the long run. Additionally, the weight and size of the roller compactor also influence fuel efficiency. Lighter and more compact machines require less power to operate, leading to lower fuel consumption.

Maintenance Costs

In addition to fuel efficiency, maintenance costs are another significant consideration for construction companies. Roller compactors are subjected to harsh working conditions, which can lead to wear and tear of critical components. Regular maintenance is essential to ensure the smooth operation and longevity of the machines. Maintenance costs include expenses for routine servicing, replacement of worn-out parts, and unexpected repairs.

Importance of Regular Maintenance

Proper maintenance not only extends the lifespan of roller compactors but also contributes to their overall efficiency. Regular inspections and servicing help identify potential issues early on, preventing costly breakdowns and downtime. Additionally, well-maintained machines operate more efficiently, consuming less fuel and reducing operating costs in the long term.

Cost-Effective Maintenance Practices

Construction companies can adopt several cost-effective maintenance practices to minimize the overall maintenance costs of roller compactors. Implementing a proactive maintenance schedule, including regular oil changes, filter replacements, and lubrication, can prevent major mechanical failures and reduce repair expenses. Furthermore, investing in high-quality genuine parts and components ensures the reliability and performance of roller compactors, ultimately saving on maintenance costs.

In conclusion, the fuel efficiency of roller compactors and maintenance costs are crucial factors that influence the overall operational expenses of construction projects. Investing in modern, fuel-efficient roller compactors can lead to significant cost savings on fuel consumption. Furthermore, prioritizing regular maintenance practices can minimize unexpected repair costs and downtime, contributing to the efficient operation of roller compactors. By considering both fuel efficiency and maintenance costs, construction companies can make informed decisions when selecting roller compactors for their projects, ultimately optimizing their operational efficiency and profitability.

Learn More : Roller Compactor Features for Efficient and Smooth Operation