The Ultimate Guide to Roller Compactor Maintenance Validation:

Ensuring Peak Performance, Compliance, and Longevity

Rollercompactor.net is aware of the fact that your roller compactor is not just a piece of equipment—it’s a landscaping, construction, and paving project investment in you. Precisely roller compactor maintenance extends compaction quality, work site safety, and your financial investment by organizing efficient maintenance schedules that avoid costly downtime and repairs that are early in their lifetime.

The regular maintenance will be the differentiator for the machine between a long life and a constantly breaking one. This all-inclusive guide on roller compactor maintenance will help you to perform the cleaning and servicing of your roller compactor and will offer you a user-friendly checklist to do that. A well-planned prevention maintenance calendar for any compaction device is the best way to raise the efficiency, safety, and machine reliability for any job.

Why Regular Roller Compactor Maintenance is Non-Negotiable

Not even a single professional contractor is in a position to take the risk and ignore the roller compactor maintenance. Every part of the machine undergoes heavy stresses which are a direct result of the continuous vibrations, heavy weights, and abrasive materials during the compaction job.

The break down that will now only happen at the most inopportune time without an anticipatory plan will delay project schedules and blow budgets quite exorbitantly. A planned maintenance program is a strategic capital that brings you many returns in the form of repair-free expenses and steady output.

- Maximizes Machine Lifespan and Protects Resale Value: In a similar way to a carefully maintained automobile, a roller compactor that has a complete and well-documented service history is a lot more valuable. Regular oil changes, filter replacements, and lubrication at least intervals prevent the production of internal wear and tear in your vital components like the engine, hydraulics, and drum bearings. Consequently, the operational life of machines is significantly extended. At the time you are going for an upgrade or sale, a machine that has been taken care of in a very detailed manner will be able to fetch a much higher price in the second-hand equipment market.

- Ensures Consistent Compaction Performance and Quality: Basically, the main function of the roller compactor is to get the best density of soil or asphalt. Vibratory systems that have gotten old, leaking hydraulic lines, or under-inflated tires are some of the issues that lead to the performance of the machine that is not good and low uniform compaction. What results from this is pavement quality that is below standard, the settling that will occur in the future, as well as congested areas that have to be fixed and which are entirely your company’s financial burden. Proper maintenance will ensure that on every single pass your compactor performs at the level specified.

- Dramatically Enhances Job Site Safety for Operators and Others: A compactor that is malfunctioning is a risky equipment. Faulty brakes, failed steering systems, leaking hot hydraulic fluid, or cracked drums are the factors that can lead to catastrophic accidents. Regular inspections and maintenance not only help in identifying such potential hazards, but they also do it before the hazard can injure the operator or the other workers on site. So, a safe working environment is guaranteed, and the company is protected from liability.

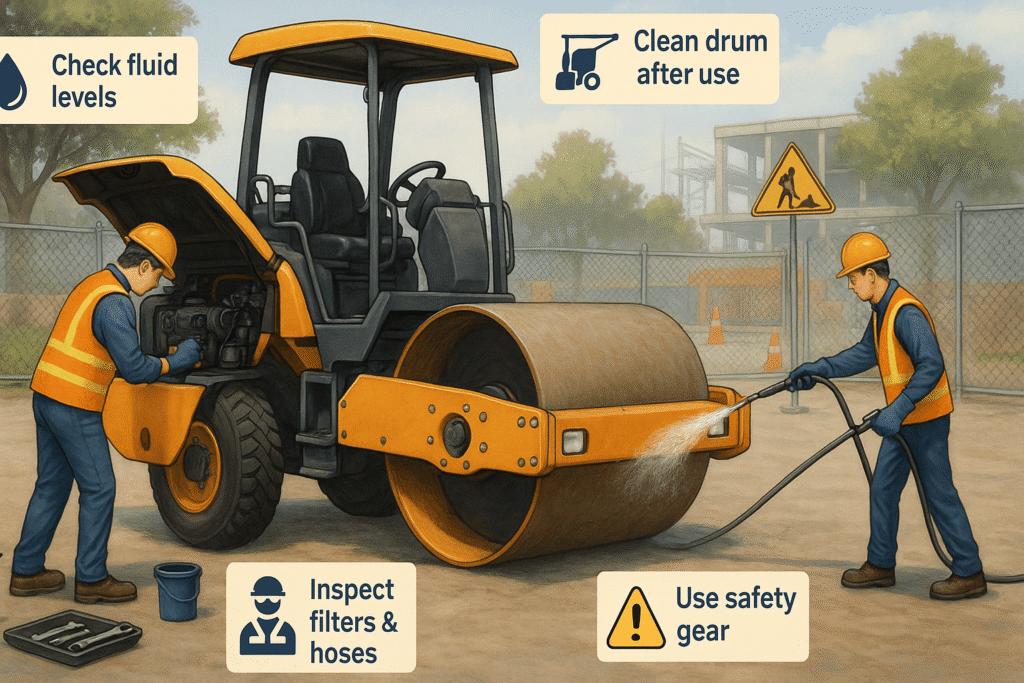

Daily Cleaning and Maintenance:

The daily walk-around and clean-up can appear to be boring, yet they are the most essential habits that an operator can adopt. Through this 10-15 minutes routine, small issues are identified before they escalate to bigger, costly problems. Thus, the procedure has to be done at the end of the shift when the unit is still warm, and any leakages or changes are simpler to notice. This kind of activity is the backbone of good compaction equipment upkeep and construction equipment care.

- Conduct a Thorough Walk-Around Inspection: Turning off the engine is the time when you inspect the machine visually. Look for obvious signs of damage, such as dents, cracks, or deep scratches on the drum, and the shell. Check whether there are any loose bolts, nuts, or fasteners. Examine the frame and cowling for any structural issues that may have occurred during the day’s work.

- Remove All Debris and Built-Up Material from Critical Areas: Use a putty knife, wire brush, or high-pressure air to scrub off all dirt, mud, gravel, and asphalt buildups from the drum(s), wheels, frame, and cooling packages. The built-up material on the drum can get dry and harden, resulting in an uneven compaction surface and potential damage to the drum. At the same time, debris on the engine or hydraulic cooler can cause overheating, which is the main reason for the occurrence of major engine failure.

- Check for Visible Fluid Leaks and Inspect Fluid Levels: Slide on your knees and look under the machine for any fresh puddles or drips of oil, hydraulic fluid, or coolant. Find out where the leak is coming from immediately. Put the machine on a level surface and turn it off, then check the levels of engine oil, hydraulic fluid, coolant, and fuel. Add the fluids that you have run out of with the ones recommended by the manufacturer of the machine.

Weekly and Monthly Maintenance: Digging Deeper

While daily checks are mainly about prevention and observation, weekly and monthly tasks usually require replacement, adjustment and part cleaning. Here you deal with the wear items that are of the highest importance to the machine’s function. Without a doubt, devoting time to this level of roller compactor maintenance service is what keeps you out of trouble in the long run.

- Lubricate All Grease Points and Pivot Points: In your operator’s manual, try to see each and every grease fitting (zerk) on the machine . The list should include drum bearings, pivot points for the steering and articulation joints, and any other parts that are moving. Use a high-quality, high-pressure grease and pump fresh grease into each fitting until you see the old grease purged out. This procedure is in fact removing the contaminants and it is guaranteeing that a protective film is always present on the metal components that are moving.

- Inspect and Clean Air, Fuel, and Hydraulic Filters: Check air filter indicator (if available) or visually check the main air filter for too much dirt and debris. If the filter is clogged, tap it out gently or change it if need be. Also, inspect the fuel filter and the hydraulic return filters for water or contamination.

- Examine the Drum or Wheels for Signs of Wear and Damage: Get very close to the compaction surface. For steel drums, try to see any cracking, scarring, or significant wearing. For rubber-tired compactors, tire pressure certified with a calibrated gauge (the incorrect pressure is one of the main reasons for poor compaction) and the tires for cuts, bulges, or uneven wear patterns should be checked. Any problems that you find, do not wait to solve them.

Seasonal and Annual Maintenance: The Major Service

An annual service at the end of the season or during a scheduled downtime is, for most operations, the best way to get the equipment ready for a long storage or for the intensive work of a new season. The roller compactor maintenance service usually takes longer and more complicated tasks that may require the assistance of a trained technician. This roller compactor maintenance guide method assures that nothing is left out.

- Change All Fluids and Filters Comprehensively: This is not just topping off—this is a complete flush and replacement. In addition to the engine oil and oil filter, hydraulic oil and hydraulic filter(s), and coolant should all be changed. Fluids, over time, break down and lose their protective qualities, as well as becoming contaminated with metal particles and other debris. Fresh fluids are the lifeblood of your machine.

- Inspect and Adjust the Vibratory System Components: Your compactor’s vibratory system is the power source. A technician with enough capacity should check the security of the vibration motor, the eccentric weights, and the drive belts for the signs of wear, cracks, or looseness. Small causes of disalignment or unbalance in such a system will become the source of harsh destruction of the whole machine.

- Check and Tighten All Bolts, Nuts, and Electrical Connections: Vibration is the main reason for loosening of fasteners, which over time. Use a calibrated torque wrench to go over the entire machine and retighten all critical bolts and nuts to the manufacturer’s specifications.

Meanwhile, checking the battery terminals for corrosion and, in turn, absolute electrical connections which are clean, tight, and free of damage.

Roller Compactor Maintenance Checklist

Table: Roller Compactor Maintenance Checklist

| Frequency | Task | Check |

|---|---|---|

| DAILY | Walk-Around Inspection (look for damage, leaks, loose parts) | □ |

| Clean Drum/Wheels & Undercarriage (remove all debris, asphalt) | □ | |

| Check Engine Oil Level | □ | |

| Check Hydraulic Fluid Level | □ | |

| Check Coolant Level | □ | |

| Check Fuel Level | □ | |

| Check Tire Pressure (if applicable) | □ | |

| Clean Air Cooler & Radiator | □ | |

| Test Lights & Horn | □ | |

| Check Brake Function | □ | |

| WEEKLY | Lubricate All Grease Fittings (drum bearings, joints, pivots) | □ |

| Inspect Air Filter (clean/replace if needed) | □ | |

| Inspect Water Trap/Fuel Filter | □ | |

| Check Battery Terminals for Corrosion | □ | |

| Inspect Operator Cab/Seat/Seatbelt | □ | |

| MONTHLY | Detailed Drum/Wheel Inspection (for wear, cracks, damage) | □ |

| Inspect Hydraulic Hoses & Lines (for leaks, cracks, abrasion) | □ | |

| Test Safety Systems (emergency stop, backup alarm) | □ | |

| Inspect Splitting Brakes (if equipped) | □ | |

| ANNUALLY | Change Engine Oil & Filter | □ |

| Change Hydraulic Oil & Filter(s) | □ | |

| Change Fuel Filter | □ | |

| Flush and Replace Coolant | □ | |

| Professional Vibratory System Inspection | □ | |

| Retorque Critical Bolts & Fasteners | □ | |

| Full Electrical System Check | □ |

Advanced Tips for Optimal Performance and Longevity

The benefits of going beyond the outlined duties can be tremendous in performance and in savings. This type of equipment maintenance represents the highest level of a master equipment stewardship program.

Properly Store Your Compactor to Prevent Weather and Environmental Damage:

If your compactor is out of commission for a long time, storage it inside a clean, dry, and ventilated shed or warehouse. In case there is no possibility for indoor storage, get a first-class, breathable, and weather-resistant cover for it so that rain, snow, and UV will not damage the hose and the wire of the machine.

Keep Detailed Maintenance and Service Records for Your Equipment:

Maintain a record of each service, repair, and inspection by means of a logbook or digital software. State the date, machine hours, tasks done, fluids and parts used, and who did the work. This documentation is very helpful in the process of finding the origin of the same problem, guaranteeing warranty rights, and reassuring future buyers of your equipment.

Commit to Operator Training to Ensure That the Machine Is Used Correctly and Efficiently:

An informed worker is the best of your repair tools. Make sure they are completely trained on the specific model of compactor, having knowledge of its features, restrictions, and best operating methods (e.g., proper vibration settings for different materials, correct overlap between passes). Regular operation power by which wear and tear are in the last and job quality improved.

Strategic Verdict: Maintenance is an Investment, Not a Cost

A good and careful approach to the disassembling and maintenance of your roller compactor is the main factor that distinguishes the two types of operations: one stands out for its success and profitability, the other for its constant interruptions caused by downtime and repair costs.

By executing the daily, weekly, and annual routines as shown in this manual and strictly applying the compactor maintenance checklist provided, you are not only maintaining a piece of equipment; instead, you are protecting your working hours, your image as a quality contractor, and the safety of every person on your job site. Be aware that regular maintenance is your cheapest strategy.

In case of the need for a roller compactor maintenance, whether it is for products or services, you may always rely on rollercompactor.net to deliver quality work at its best. Your partner in performance.

Frequently Asked Questions (FAQs)

How often should I grease my roller compactor?

Compactors should be greased at all locations specified in the figures daily or after every 8-10 hours of work. If the conditions are severe (extreme dust, wet, and asphalt work), greasing should be done even more often. Always take note of the specific intervals pointed out by the manufacturer in the owner’s manual.

What is the most commonly overlooked maintenance task?

The cleaning of the radiator and hydraulic oil cooler could be the most ignoring maintenance tasks. Operators often clean the drum but forget that the current overheating of the engine and the hydraulic system is due to clogged coolers only. Releasing compressed air into these coolers at the end of every shift is a must.

Can I use water to clean hot asphalt off my drum?

Definitely not. The action of spraying cold water on a hot steel drum is capable of giving the metal a thermal shock, which can cause the drum to be warped or cracked. The best solution is to let the asphalt solidify first and then use a scraper or a putty knife for the removal. In that case, there is a good number of technicians who use a special release agent which is certified for a drum to prevent sticking.

Why is my roller compactor losing vibration?

The loss of vibration is a symptom of several problems: a drive belt that is loose or has been broken, a malfunctioning vibration solenoid valve, the low pressure of hydraulics, eccentric shaft bearings that are in trouble, and issues with the operator control switch. A certified technician usually has to do the troubleshooting to solve this problem.

How do I know if my drum bearings are failing?

The signs of bearing failure that appear early are the strange grinding or rumbling noises that come from the drum area, too much heat from the drum hub (a laser thermometer can be used to check), and grease that leaks out from the seals. Metal shavings in the grease while purging is a sign of a broken bearing.

What type of hydraulic fluid should I use in my compactor?

Only use the fluid that matches the specification mentioned in the manual of the equipment by the manufacturer. Wrong fluid usage will lead to failure of the pump, valve malfunction, and the occurrence of leakages due to the wear on seals and hoses. The manual will state the required viscosity grade and performance standard as well as specify (e.g., AW46, AW68, or an OEM-branded fluid) directly.

Is it worth the effort to keep an older roller compactor in good shape?

Definitely. A well looked after old machine can serve you for a long time and be very much cost-efficient. The real question is about the history of its maintenance. Say it has been well taken care of, then it is almost always more economical to invest in the maintenance and repair works than to do the monthly payments for a new machine.

On the other hand, if an older machine has been left with no maintenance to the extent that the body is severely damaged, then the costs of obtaining the major repairs (like a complete overhaul of the engine or hydraulic system) may not be justified from an economic point of view.