Static Tandem Rollers vs Vibratory Tandem Rollers: Pros, Cons & Applications

Compaction is absolutely crucial to any construction project that aims to produce long-lasting infrastructure. The equipment you use has a direct impact on how long your surface will last, be it an asphalt pavement on a highway or the base for a residential driveway. Thus, it is highly significant to know the trade-offs and picking features of Static Tandem Roller and Vibratory Tandem Roller. Both types feature the signature double-drum design, however, their operating principles and compatibility with various materials vary quite a bit.

Choosing the wrong tool might result in issues such as premature cracking or uneven settling of layers. On the other hand, making the right choice will get a job done quicker and more energy-efficient while giving results that no one can refuse.

This insider’s guide puts the technicalities, benefits, and use cases of these two market leaders under the microscope for you to pick the winner of your next round.

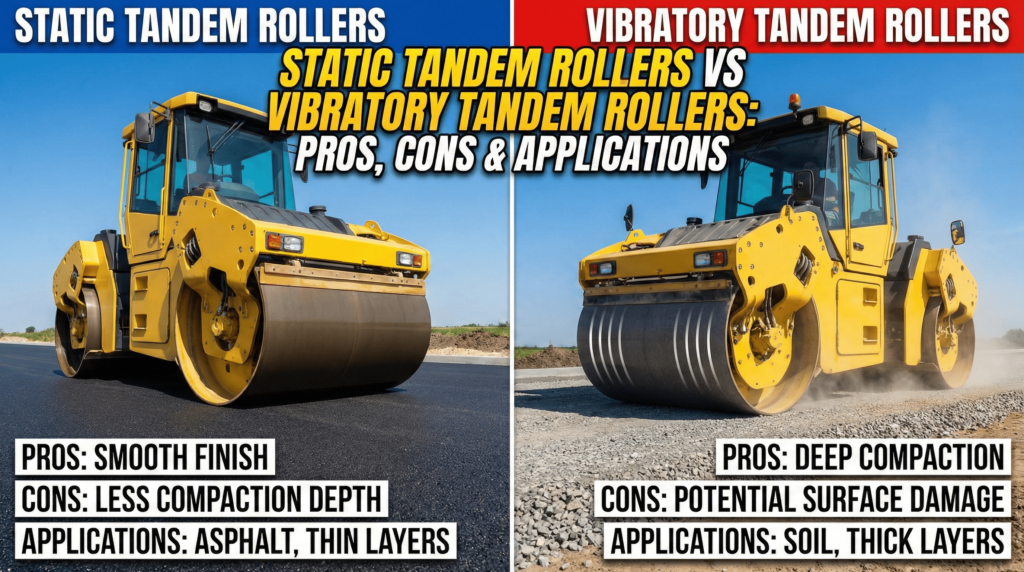

Top 7 Features of Static Tandem Rollers vs Vibratory Tandem Rollers

1. Knowing Static Tandem Rollers

A static tandem roller or a “smooth wheel roller” gets its compacting force entirely from the weight it imposes on the ground. It doesn’t have any vibrating mechanism inside, so it is very straightforward and extremely steady while working. These machines are the “slow giants” on a construction site because they release consistent pressure that fits perfectly with reined-in environments.

- Main Function: Derives portion of the pressing force from static load (kg/cm) for compressing surface air pockets and compacting the material.

- Strictly Suitable Materials: Perfect for finishing asphalt layers and works well when compacting cohesive soils like clay or silt.

- Operational Quietness: These rollers produce substantially less noise level as they don’t have vibrating parts and thus become an ideal choice in residential areas for night-time operations.

Static rollers mostly serve in the final stage of the road “polishing”. As they refrain from using dynamic force, they reduce the risk of over-compacting and breaking the aggregate in the asphalt mix, thus they make sure the surface is both nice to the eye and structurally sound.

2. Vibratory Tandem Rollers

Vibratory tandem rollers are a high level of efficiency in a single machine. These rollers add the static weight of the drums to the dynamic force generated by eccentric weight inside the drum. This “double-action” mechanism enables material to be compacted deeper and to a greater density in fewer passes than when using static rollers.

- Compaction Depth: The strong vibrations may reach deeply into the soil, thus particles of the soil are more effectively rearranged to make an empty space-less soil.

- Speed and Efficiency: Basically, the time needed to reach a specific density (Marshall or Proctor) is almost halved when vibratory rollers are used, which speeds up the whole construction process.

- Versatility: Most new vibratory rollers come with a vibration control system which enables the operator to simply switch off the vibration and thereby convert the machine into a static roller if so desired.

When the foundation layer of a highway is expected to bear high pressures, an airfield-based vibratory tandem roller would be a great help. Its capability to process granular materials such as gravel and crushed stone makes it fit for any heavy-duty fleet.

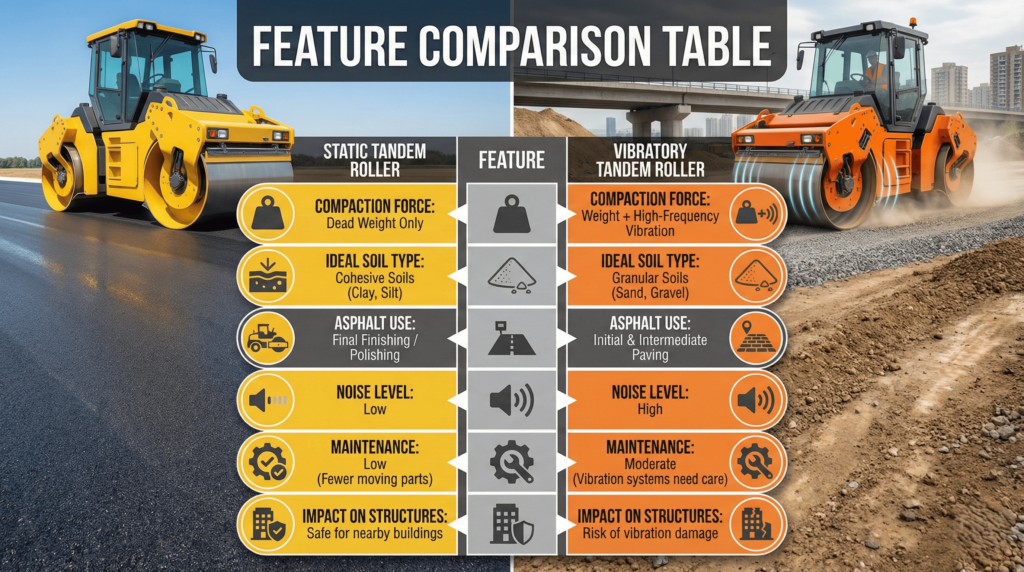

3. Comparative Analysis: Static vs. Vibratory

Before we decide which machine is better suited to your specific needs, we need to understand how they differ from each other in terms of performance on various aspects. The table below compares some of their major features in detail.

Feature Comparison Table: Static Tandem Roller vs Vibratory Tandem Roller

| Feature | Static Tandem Roller | Vibratory Tandem Roller |

| Compaction Force | Dead Weight Only | Weight + High-Frequency Vibration |

| Ideal Soil Type | Cohesive Soils (Clay, Silt) | Granular Soils (Sand, Gravel) |

| Asphalt Use | Final Finishing / Polishing | Initial & Intermediate Paving |

| Noise Level | Low | High |

| Maintenance | Low (Fewer moving parts) | Moderate (Vibration systems need care) |

| Impact on Structures | Safe for nearby buildings | Risk of vibration damage |

4. Static Tandem Rollers Pros & Cons

No doubt every machine has its upsides and downsides. Static rollers, for instance, are well-known for their simplicity but they cannot compete with the pace of vibratory ones.

Pros:

- Enhanced Surface Finish: They are able to create an even and unmarked surface without the “ripples” that can sometimes be a result of vibration.

- Structural Integrity: A great choice for working on infrastructure such as bridges, overpasses, or even near old heritage buildings, where vibrations may lead to cracks.

- Economical Maintenance: Without vibrating shafts and eccentric weights, there are fewer parts that can break. Thus, the cost of repairs in the long run goes down.

Cons:

- Lack of Speed: Due to the necessity of more passes for achieving desired compaction, tasks that require a big area may see high labor/fuel costs if heavy equipment is not used.

- Depth Limitation: Only the top few inches can be effectively compacted by static pressure; hence it is unsuitable for deep soil stabilization practices.

- Granular Soil Incompatibility: It totally fails in compacting sand and gravel… because these two materials have to be “shaken” to get properly settled.

5. Vibratory Tandem Rollers Pros & Cons

Vibratory rollers have great power but unfortunately, they demand a highly-skilled operator to avoid hurting the very material they are trying to compact.

Pros:

- Extremely High-Density Compaction: It can go up to a level of density so high that it would be a desired attribute of the roads which will become a very frequent subject to heavy traffic loads.

- Fast Operation: Its capacity of compaction of a thicker layer in a smaller number of passes may lead to very significant project duration shortening.

- Settings Adjustability: The two parameters that the operator may choose to make use of are frequency and amplitude of vibration. These then can be fitted to the specific type of the material that has to be rolled.

Cons:

- More costly at the beginning: Due to the involvement of technology in its vibration system, this kind of machine generally has a high purchase or rental price.

- Environmental Effects: Noise and ground vibrations can cause disruption to houses and ecology in the vicinity.

- Over-Compaction Danger: In case one uses vibration on thin layers of asphalt, the aggregate will most probably become broken, which leads to the weakening of the surface of the road.

6. Applications in Modern Construction

It’s not just a matter of the machine when choosing between static and vibratory; application matters. They both have their strong suits in the specific parts of a project.

Road Construction and Paving:

- Base Layers: Vibratory rollers are usually used on the sub-base (gravel/stone) to perfect the stability of the foundation.

- Asphalt Mat: Vibratory rollers are used during the “breakdown” pass of the asphalt paving process which locks the asphalt securely in place.

- Surface Finish: Static rollers are used for the “finish” pass to get rid of markings and the surface appears crystal smooth.

Industrial and Commercial Projects:

- Parking Lots: Small vibratory tandem rollers are ideal for the blended materials used in commercial lots of considerable size.

- Warehouse Floors: Static rollers serve the purposes of accurately leveling large indoor slabs whether they are made of concrete or asphalt.

- Industrial Yards: Places designated for the parking of heavy machinery, and thus, where the ground is required to bear the weight, are vibratory roller areas.

Sensitive and Urban Areas:

- Utility Trenches: Static rollers can close up the surface tightly without harming the underground pipes.

- Bridge Decks: To maintain the structural stability, the use of a “Static-Only” mode is strictly adhered to in the case of bridges.

- Residential Patches: Small, quiet static rollers minimize disruption to local residents.

7. Maintenance and Longevity Tips

Whichever type of roller you have—static or vibratory—keep it up to its very best condition by following a maintenance schedule.

- Daily Drum Inspections: Frequent checks for the presence of debris or the accumulation of asphalt on the drum can help to avoid the damage of the finish of your road.

- Hydraulic System Checks: Hydraulics constitute the major part of the steering and drive systems in both types; therefore, you should keep an eye on any potential leaks and top up the fluids as necessary.

- Vibration Unit Lubrication: The eccentric weights of vibratory models have to be lubricated according to manufacturer’s recommendations to avoid the risk of a major mechanical breakdown.

Frequently Asked Questions – Static Tandem Roller vs Vibratory Tandem Roller

Which roller is better for asphalt compaction?

Both types are utilized. For an initial breakdown to accomplish density, a vibratory tandem roller is employed, whereas the final finish pass to a smooth and unmarked surface is done with a static tandem roller.

Are vibratory rollers capable of damaging nearby buildings?

Vibrations traveling through the ground have the potential to cause cracks in the foundations or the windows of the surrounding structures, and this is particularly the case if the structures are older. In such situations, one would be best advised to use the static mode.

Why are static rollers preferred for cohesive soils like clay?

Cohesive soils are more responsive to a steady and heavy pressure that causes the moisture and air to be expelled. On the other hand, vibration may lead to the clay being “sheared” or losing its structural bond rather than getting compacted.

Are vibratory rollers more expensive to keep in good condition?

Mostly, yes. This type of work requires a lot of attention since there are several moving components, notably the vibration motor, eccentric shafts, and shock-absorbing mounts, that need to be inspected regularly and replaced when necessary.

How do I choose between a single-drum and a tandem roller?

Tandem rollers are more of a specialty when it comes to asphalt and surface finishing because they have two steel drums. Single-drum rollers (with rear tires) fare better on the rough earthwork and are ideal for steep grade climbing.

What is the average weight of a tandem roller?

From “mini” versions (1-2 tons) used for sidewalks to heavy-duty models (10-15 tons) for major highway construction, tandem rollers come in the various sizes.

Is it possible to use a vibratory roller on a bridge?

Generally, it is advised to refrain from using the vibratory function on bridge decks as it could lead to structural resonance and damage. In most cases, engineers require the use of “Static Mode” only for bridges.