Smooth Drum Rollers: Delivering the Perfect Finish for Asphalt & Granular Soil

In a rapidly changing industry of heavy construction, road building, etc. success lies in a strong durable foundation. A solid and reliable foundation can be underlying factor for a project to get longevity and another one may just get deteriorate. A smooth drum roller, the very machine which accompanies paving these days along with earth moving equipment at site, was there at the epicenter of this method.

With a smooth drum roller, you can get a high-density compacted surface with an unbeatable finish whether you are sealing with miles of highway asphalt or going down to granular sub-base for a commercial foundation.

To make these surfaces smooth and at the same time strong, basically, these rollers use a combination of weight and vibration to bring particles closer together, rearrange soil particles, and create a surface that is both smooth and structurally sound.

Roller Compactor completely comprehends that the task of choosing the right machine and learning how to operate it are the biggest challenges in a construction path. Here, we not only talk about the components, uses, and methods of smooth drum rollers, but we also equip you with the correct knowledge to do the finishing perfectly and without fail on every job.

What is a Smooth Drum Roller?

A smooth drum roller, is an industrial compactor device which is usually identified by its big steel smooth cylindroid drum.

Unlike padfoot rollers which are equipped with tapered lugs for kneading cohesive soils like clay internally, the smooth drum roller externally has a flat steel surface. This flat surface is specially designed to work with non-cohesive materials like sand, gravel, crushed rock, and asphalt.

The main goal of the smooth drum rollers is to make the top layer capable of bearing load and durable, also they reduce permeability while avoid potential settling problems in the future.

These days, these types of machines have turned into really advanced pieces of equipment with sophisticated hydraulic systems, adjustable vibration frequencies, and operator stations completely designed for comfort to get maximum productivity.

When the drum vibrates, it sends shockwaves deep into the substrate, forcing particles to interlock tighter than static weight alone could achieve. This combination of weight and vibration makes them the preferred option on the market for finishing layers of material.

- Granular and asphalt compaction: Allow the compaction of granular soils and asphalt without causing surface damage as would be the case with padfoot rollers.

- Rolling at two modes: Static rolling (finishes) and vibratory rolling (deep compaction) are the two operations that most models support.

- Surface finishing: Produces a smooth, even surface which is necessary for the final wearing courses of roadways.

Main Principals of a Smooth Drum Roller

The broad usage of the smooth drum roller has established it as an unavoidable piece of gear in the construction industry. Mainly, this tool handles with the granular soils – materials which get their strength from friction between the particles.

While preparing a sub-base, the smooth drum roller will run the sand and the gravel tightly together to form a rigid, close-knit layer that will not shift under loading scenarios such as concrete or asphalt.

Nevertheless, it is its role in asphalt paving which is most observable. At such, the road roller is both the lead and finish roller. It follows the paver so as to break down the hot mix asphalt (HMA) and reach density.

Once done it, it is moved to static mode to remove any wrinkles or marks left by the roller, thus giving the glass-smooth surface desired by the drivers. In commercial and landscaping projects, too, it is indispensable when it comes to ground leveling for sodding or driveway laying.

- Road construction: An absolute must for the sub-base, base course, and the final asphalt wearing course compaction.

- Commercial developments: Helps in the ground preparation for facilities like parking lots, industrial floors, and large building pads.

- Municipal utilities: Perfect for pothole repair and street resurfacing projects where smooth transition is crucial.

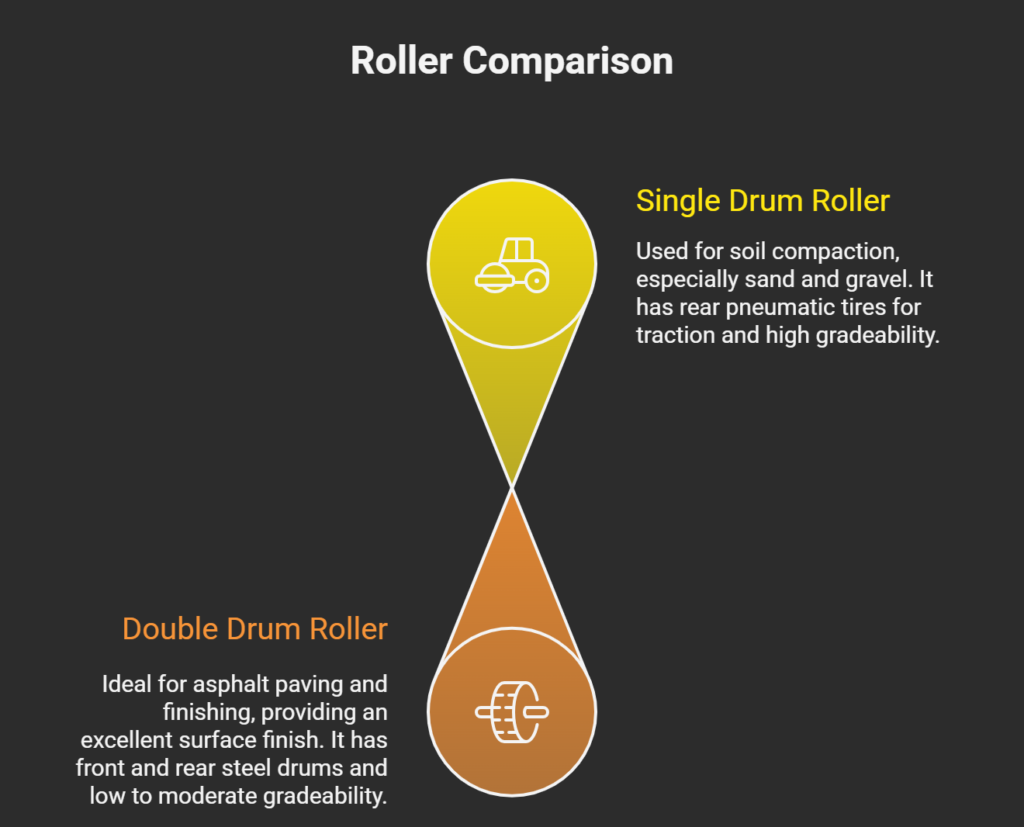

Single Drum vs Double Drum: The Decision is Fun But It is to the Point

A smooth drum roller is one of the typical road machines and therefore, the choices one has to make is between the two most common configurations – single drum and double (tandem) drum.

Any single smooth drum roller comprises of a large steel drum as a majority of the weight is supposed to be on the drum while the rear is equipped with pneumatic rubber tires. Such a configuration provides the machine with ample traction, and this is why it is used mostly for soil compaction on rough terrain or on a slope.

The fact that the rear is a tire endows a single drum roller with the ability to push itself up. The single drum performs the heavy compaction task whereas the rear tires propel the machine. By contrast, a double drum roller truncates the tires from the rear and replaces them with a second steel drum.

By doing so the extent of compaction at one time is virtually doubled and such a machine is thus the phenomenon in the world of asphalt paving. The absence of tires also means less impact on the fresh asphalt than tires rolls would, and the tandem roller can go on rolling without ‘scuffing’ or marking the hot mat.

Recognizing and comprehending the special features of each machine type will prepare you for properly deploying a machine not only by material but also by terrain.

- Traction differences: Single drum units offer better gradeability on loose soil due to rear rubber tires.

- Finish Quality: Double drum units are superior for asphalt as they leave no tire indentations and provide a flatter finish.

- Maneuverability: Tandem rollers often feature articulated steering that allows the drums to track perfectly, essential for precise curb work.

Table: Comparison: Single Drum Roller Vs Double Drum Roller

| Feature | Single Drum Roller | Double Drum (Tandem) Roller |

| Primary Use | Soil Compaction (Sand, Gravel) | Asphalt Paving & Finishing |

| Traction System | Rear Pneumatic Tires | Front & Rear Steel Drums |

| Gradeability | High (Good for slopes) | Low to Moderate |

| Surface Finish | Good (May leave tire marks) | Excellent (Flawless finish) |

| Compaction Depth | Deep (Sub-base focus) | Shallow to Medium (Layer focus) |

The Science Behind the Vibratory Smooth Drum Roller

One who carries the ambition to become a proficient operator of a smooth drum roller must first comprehend the science behind the vibration system which is the fundamental principle underlying the operation of a vibratory roller.

A vibratory roller applies oscillation rather than simple rolling for compaction. This is achieved by rotation of the eccentric weights which are inside the drum. The rotating weights cause a centrifugal force. This force is “subscribed” by two parameters: amplitude and frequency.

Amplitude is the vertical distance the drum moves during one complete vibration cycle. In other words, it is a measure of how-strongly the drum hits the ground. This parameter is usually low for asphalt layers but can be high for thick layers.

Frequency is inversely related to amplitude and refers to the number of blows per unit time. You should go for a high frequency in situations where you have thin layers such as asphalt finishing because it prevents the drum from bouncing and thus the occurrence of a “wave-like” pattern.

It’s the job of today’s operators to determine the settings of amplitude and frequency based on the material type and moisture content. Without adequate knowledge, you’d just be guessing, for instance, a delicate asphalt overlay needs low amplitude but high frequency for densification without crushing the aggregate.

- High Amplitude: Ideally used for thick layers of soil or rock fill where a deep penetration of the load is needed to settle the material.

- High Frequency: Play a vital role in the last passes of roll-outs on the asphalt so that the surface gets sealed and a perfect texture is attained.

- Static Mode: In switching off vibration completely, the final ironing pass gets done removing hairline cracks and roller marks.

How to Run a Smooth Drum Roller for an Immaculate Surface?

Achieving that perfect, glass-like finish on asphalt or a rock-solid soil base requires more than just driving back and forth; it requires technique. One of the golden rules of operating a smooth drum roller is to maintain a consistent speed.

Sudden stops or starts on hot asphalt can create depressions or bumps that are impossible to remove once the material cools. Operators should also be mindful of their rolling pattern. Overlapping passes by at least 6 inches ensures uniform coverage and prevents weak seams.

When working with asphalt, temperature is time. Rolling when the mix is too hot can cause the mat to shove or displace, while rolling when it’s too cold will result in inadequate density and a porous surface.

Furthermore, utilizing the water spray system is non-negotiable on asphalt to prevent the hot, sticky material from adhering to the steel drum and tearing up the fresh mat.

- Speed Control: Maintain a steady, slow pace (usually 2-3 mph) to allow the vibratory energy to penetrate the material effectively.

- Pattern Management: Establish a consistent rolling pattern, working from the lower edge toward the center on crowned roads.

- Water Usage: Make sure to keep the spraying nozzles in good condition so that the drum is always wet thus preventing asphalt pickup and possible surface damage.

How to Take Care of Your Roller for a Long and Healthy Life?

A smooth drum roller is a sizable expense, and one’s most efficient means of defending his or her investment is through regular maintenance. Vibration is one of the most important parts of how a roller works, which is also the reason that the screws, bolts, etc. can get loose-naturally over time.

Therefore, it is absolutely imperative to do daily walk-around inspections. Drum scrapers are important components. They simply help the drum stay clean, and if they happen to be worn or misaligned, not only will the drum collect the material but the material will get pressed out onto the smooth surface, in other words, the finish is ruined.

Furthermore, hydraulic system is a big concern as the vibratory mechanism exerts great amount of heat and stress on the hydraulic fluid. For this reason, regular changes and checking the level of hydraulic fluid are a must.

The shock mounts, or rubber isolators that insulate the vibrating drum from the chassis and operator cab, are other parts that need regular checking for cracks. Badly worn shock mounts not only make the operator’s working environment uncomfortable, but they also lead to the transmission of harmful vibrations to the frame and engine parts.

- Scraper Maintenance: Regularly adjust and replace drum scrapers to ensure the steel surface remains perfectly clean during operation.

- Vibration System Care: Monitor oil levels in the eccentric weight housing and check shock mounts for signs of fatigue or tearing.

- Fluid Hygiene: Keep hydraulic fluids and engine oil clean, as the dusty environment of compaction sites is the enemy of precision machinery.

What Makes RollerCompactor.net Stand Out from the Rest?

RollerCompactor.net is not just an ordinary marketplace; it is a gathering place of knowledge and experience in the densification industry. No matter if you need a pavement roller for a heavy consumption/highway project or a smaller one for a residential break-your-back driveway, our product range is designed to offer you dependable solutions that keep pace with the pressure of construction.

If compaction is a non-uniform thing – one size does not fit all – then the only way to fully understand it is by looking at specifications, maintenance, and reading expert articles. Our dedication does not stop with the sale. We provide safety, operating, and troubleshooting resource materials to help you achieve excellent operational competence.

By opting for the products and advice from Roller Compactor you are basically choosing a partner who knows the scientific background of soil and asphalt stability.

- Client Empowerment: We provide training, tips, and tools that professional contractors and DIY-ers can use to do their jobs safely and efficiently.

- Industry Expertise: Deep soil mechanics knowledge and paving technology know-how back our content and product choices.

- Comprehensive Support: We cover the entire lifecycle of your equipment from purchase advice to maintenance tips.

- Quality Assurance: Our focus is on reliable equipment capable of delivering consistent performance which translates to less downtime on your projects of high priority.

FAQs About Smooth Drum Roller

What is a smooth drum roller used for?

A smooth drum roller is primarily used for compacting non-cohesive materials such as sand, gravel, crushed rock, and asphalt. Its flat steel drum applies static pressure and vibration to eliminate air voids and increase density, making it the ideal machine for preparing road bases and finishing asphalt surfaces to a smooth, uniform texture.

When should I use a smooth drum roller vs. a padfoot roller?

You should use a smooth drum roller for granular soils (sand, gravel) and asphalt finishing where a flat surface is required. A padfoot roller, which has tapered lugs on the drum, is designed for cohesive soils like clay and silt. The “feet” penetrate the soil to knead it and break up air pockets, which a smooth drum would simply bridge over without compacting effectively.

What are the benefits of using a smooth drum roller?

The major benefits are, among other things: the ability to achieve a very high quality, perfectly flat surface finish and excellent compaction density on granular materials. They are versatile machines that can switch between static and vibratory modes, which allows them to perform both deep compaction and surface finishing. In addition, when compared to other types of compactors, they offer higher productivity on large, open areas.

Can smooth drum rollers be used on clay soil?

Not really. Smooth drum rollers are generally not the right tools for heavy clay or cohesive soil compaction. Because the drum is flat, it mostly happens that the “bridging” action generates which seals the surface thus inhibiting the compaction under the surface. Therefore, a padfoot or sheepsfoot roller is a more appropriate choice in this case as they can manipulate the soil particles and drive out air and moisture from deeper layers.

What is the difference between a single drum and a double drum smooth roller?

A single drum roller has one steel drum in the front and pneumatic tires in the back, offering better traction for soil work and inclines. A double drum (tandem) roller has steel drums in both the front and rear. Double drum rollers are preferred for asphalt paving because they cover more surface area and eliminate the risk of tire marks on the hot mat.

How do smooth drum rollers work to compact soil?

The work mechanism of a vibratory smooth drum roller involves two forces; static weight and vibration. The heavy steel drum lays down a pressing force in the downward direction while an internal mechanism with an eccentric weight produces very fast vibrations. These vibrations contribute to the reduction in friction between soil particles leading to their movement and assimilation in a denser configuration whereas weight effectively presses the particles together for their bonding.

How do I maintain a smooth drum roller?

Major maintenance requirements of the smooth drum rollers would be to keep water spray system functioning, replace worn out or damaged shock mounts, and finally clean as well as adjust the drum scrapers. Checking oil levels in the vibration system and replacing air filters are also necessary as these machines work in the dusty environment that is quite inimical to the cutting-edge machinery if the system is neglected.