One of the decisive steps, at the very least, to the successful realization of any road construction or paving project is choosing the right pavement roller for the job. A roller choice not only influences the quality and the lifespan of the asphalt surface but also affects project timelines, operational expenses, and the long-term maintenance costs.

Because of the huge diversity of roller kinds and their specs, knowing the most important features and the basic principles of their operation will help contractors and equipment buyers to make rational decisions by choosing pavement roller for the suitable job.

Today’s article will lead you through the key specifications and the deciding factors to pick out the right pavement roller for the asphalt compaction task and thus, professionals who are navigating the market on rollercompactor.net will receive the perfect assistance.

Understanding Pavement Roller Types and Their Roles

Different types of pavement rollers are available, and each of them is constructed to solve certain problems in the process of compacting the asphalt mix of a specific kind, layer thickness, and project scale.

The main roller types used in asphalt compaction include:

- Vibratory Double Drum Rollers: A device with two metal drums that works by the vibration to compact asphalt in a very efficient manner. It is mainly used for medium to large paving projects.

- Static Double Drum Rollers: Only the static weight of the roller without the vibration is used. It is better for the final surface of asphalt layers.

- Pneumatic (Tire) Rollers: Use a number of rubber tires with an adjustable pressure that ensures uniform compaction and a smooth finish.

Why Roller Type Matters

- Different types of roller can only use different forces of compaction suitable for different mixtures of asphalt.

- Vibratory rollers use both the weight and the vibration for a deep compaction while static rollers can only be used for making the surface smooth.

- Determining the right roller type for the task can result in the uniformity of the compaction, surface texture as well as the strength of the first layer of a building.

Key Specifications in Pavement Rollers to Consider

When a roller for asphalt compaction is to be a a perfect fit for the purpose of asphalt compaction it is very good idea to be mindful of the specification are as pavement.

- Operating Weight

- Generally, a heavier roller will be able to provide more static pressure and a greater depth of compaction.

- The weight of the roller changes with the size of the machine; the weight of a vibratory tandem roller is normally between 1.5 and 15 tons.

- Certainly, a lighter roller is capable of thinning out the layers of asphalt and in doing so it will avoid over-compaction and therefore surface cracking.

- Drum Width and Diameter

- The larger the drum width the bigger will be the surface that the roller can accommodate at one pass and hence the more efficient will be the work of a large flat area.

- The bigger the diameter of the drum the more efficient the contact surface will be between the soil or asphalt and the drum and also more smooth the compaction.

- Compact drum width is very useful for small-scaled projects as well as for the narrow ones that require accurate maneuvering.

- Vibration Frequency and Amplitude

- The vibration frequency (cycles per second) is the factor that determines how quickly the compaction impacts the asphalt.

- The amplitude shows the extent of the movement of the drum, which means it affects the depth and also the intensity of the compaction.

- It is the adjustment of the vibration that makes possible to link the performance of a roller with different mixes of asphalt and conditions on site.

- Drum Thickness and Surface Texture

- The size of the metal part covering the drum is what decides how strong it will be and for how long it can be used under heavy work conditions.

- Smooth and even drums serving for compacting are put on asphalt surfaces, whereas padded or sheepsfoot drums being used for soil compaction are chosen.

- Centrifugal Force

- The force that is called into action when the drum vibrates to produce the compaction force is the centrifugal force.

- Basically, if the centrifugal force is increased, the machine will be able to do its task more efficiently, i.e., compacting dense asphalt layers.

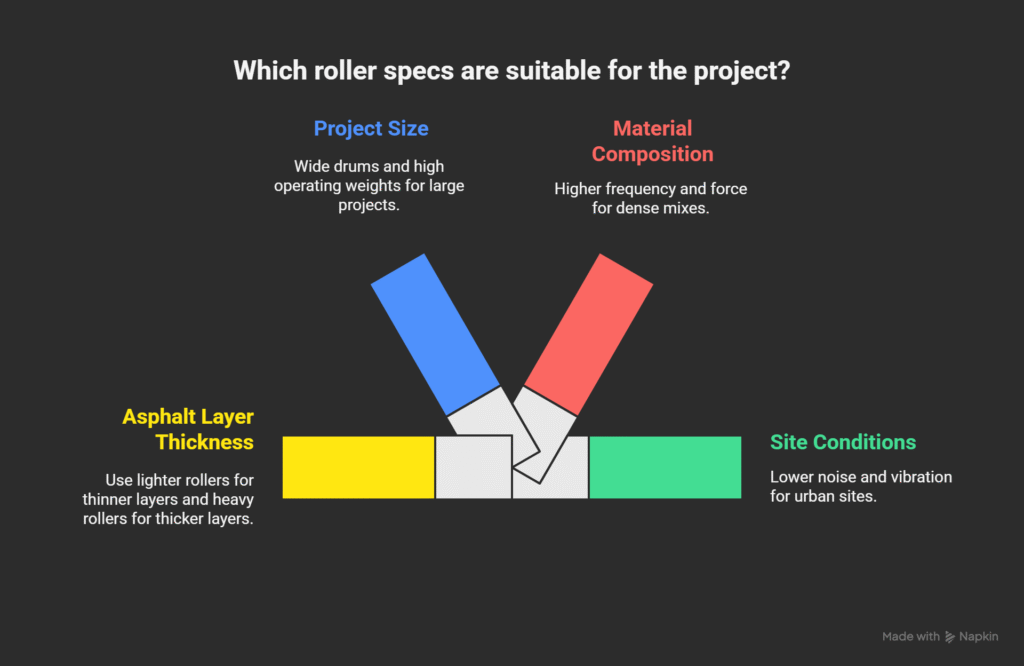

Matching Roller Specs

The correct specs of a roller can be determined by numerous variables of the project:

- Asphalt Layer Thickness: In the case of thinner layers it is recommended to use lighter rollers with lower amplitude; if it is a thicker layer a heavy vibratory roller will be necessary.

- Project Size: Large highway projects are those that will get the most benefit from the use of wide drums and high operating weights for productivity.

- Material Composition: Premium dense-graded mixes might require higher frequency and force for full compaction.

- Site Conditions: For example, urban sites that could be in need of rollers with lower noise and vibration for environmental compliance.

| Specification | Effect on Compaction | Ideal Use Case |

| Operating Weight | Deeper compaction with heavier weight | Heavy-duty, thick layers |

| Drum Width | Efficiency on wide, flat surfaces | Large-scale paving |

| Vibration Frequency | Controls compaction speed and depth | Variable asphalt mixes |

| Centrifugal Force | Compaction intensity | Dense materials, thick layers |

Advantages of Vibratory Tandem Rollers

For asphalt, vibratory tandem rollers are still the most widely accepted option, mainly because they bring together the elements of weight and vibration to double the effect:

- Enables uniform, thorough compaction going deep into layers of the pavement, thus guaranteeing structural strength of the road.

- The settings of the vibration controls can be changed to suit different asphalt mixes and conditions, thus obtaining the best results.

- The tandem drum layout is what makes the compaction even and thus the surface getting the required finishing smoothness.

When to Consider Pneumatic (Tire) Rollers

A pneumatic roller is used along with a steel drum roller to make a surface more even and to seal it:

- The pressure is evenly distributed by several tires, thus a uniform density is produced throughout the asphalt surface.

- The pressure of the tires that can be adjusted allows the setting of the compaction level to meet the local needs of the project.

- It is mainly applied after the vibratory rolling to facilitate surface sealing and thus, to stop the moisture from getting into the material.

Maintenance and Operator Considerations

Assessment of maintenance and operator skill levels should also be a part of the roller choice process:

- The area of vibratory roller performance is always maintained by regular checks on the vibration system.

- Operators should be instructed how to adjust vibration amplitude and frequency for different types of asphalt.

If the maintenance schedule for the hydraulic, engine, and drum parts is adhered to, the machine will be kept for a longer time in a condition suitable for use and will make a higher-quality compaction.

Summary: Pavement Roller – Making the Right Roller Choice

The selection of the right pavement roller is a combination of understanding both the project details and the roller capabilities. In most cases, vibratory double drum rollers present the best mixture of power, accuracy, and velocity thus making them the most suitable for the task of asphalt compaction in a variety of projects.

This tandem will be the most efficient in the stabilizing and the prolonging of the life of the pavement, followed by pneumatic rollers for the finishing.

Spend time with this extra work in your next endeavor with rollercompactor.net where you can find details and a variety of asphalt rollers with different specs. This will enable you to pick out the best equipment for the job at hand.

Pavement Roller Frequently Asked Questions (FAQs)

What would be the best operating weight for a road compaction roller?

The most suitable weight changes with the scale of the project and the thickness of the asphalt and normally for vibratory tandem rollers, it is between 1.5 and 15 tons.

In which ways does the vibration frequency influence the quality of the compaction?

At a higher vibration frequency the speed of the compaction also increases together with the depth, but this frequency must be appropriate for the type of asphalt in order to prevent any kind of damage.

When is it that I ought to use a pneumatic roller for heavy-duty rolling?

The best usage for pneumatic rollers would be working on a surface that is already compacted by a vibratory method in order to seal the surface and ensure uniform density.

May I utilize a static roller for asphalt compaction?

To what extent is the effort of a static roller reduced in comparison to that of a vibratory one in the case of asphalt, though it can be used for final surface smoothness in some applications.

What are the most important maintenance tasks ought to be done on vibratory rollers?

Main maintenance on the machine should be regular lubrication, and checking parts that take part in the movements, hydraulic, and vibration systems as well as the drums.

How do drum width and diameter impact paving efficiency?

By being both wider and of a larger diameter drums are able to cover more area as well as to provide smoother easing operation however they do require an adequate site space and power provision.

Are operator skills important in achieving optimal asphalt compaction?

Yes, skilled operators adjust vibration settings and roller speed, impacting compaction quality and surface finish.