Vibratory tampers are one of the must-have compact power tools that can inflict heavy-impact compaction in tight spaces, which means that they are a necessity for road crews that work in accurate and hard-to-handle areas.

Why Vibratory Tampers are Special?

To do this, they employ a base plate that is loaded with a spring to generate very fast vibrations which make the soil, gravel, or any other granular materials tightly packed thus making the foundation of roads, trenches, and utility installations very solid and safe.

Apart from larger compaction equipment, vibratory tampers are preferred in hard-to-reach places that are of utmost importance such as alongside curbs, inside narrow trenches, or near structural elements, where their portability can be taken advantage of.

With their small design and concentrated compaction power, road workers have the ability to achieve the ideal soil density without endangering the neighboring structures.

Due to the improvements in engine performance and ergonomics, today’s vibratory tampers herald better operator comfort, lower emission levels, and their high durability turn them into a lasting, cost-saving solution for everyday and special compaction jobs in road construction and maintenance projects.

Why Vibratory Tampers Are Necessary for Road Crews

Vibratory tampers are instrumental in bringing about the soundness and time span of a road construction project through the delivery of pinpointed compaction in places where a large machine cannot reach.

Because they are able to carry out their tasks in very close quarters, they are the best choice when it comes to trench backfill, soil compaction around utility lines, and subgrade preparation under curbs and retaining walls.

Failure to compact these areas properly may cause differential settlement with the result that pavement will develop cracks, potholes, and even pose risks to people’s safety.

Vibratory tampers lessen these risks since they perform uniform and very frequent strikes that rearrange soil particles in a denser form thus voids left by air are taken out and the capability for bearing the load is increased.

This accurate compaction is the mainstay of the stability of the road surface as it keeps the occurrence of the maintenance issues at the lowest possible level, thus it saves the project time and money.

- Superior Performance in Confined Spaces: Vibratory tampers are built to easily find their way into the bottom of narrow trenches and tight corners where the foot of usual plate compactors or rollers cannot reach, thus completing uniform compacting of the whole job site.

- Enhanced Soil Density and Stability: As the implement employs rapid vertical blows, that helps to achieve better compaction efficiency in cohesive and semi-cohesive soils thus the risk of post-construction settlement is lowered.

- Increased Project Efficiency and Safety: These devices are of a lightweight and portable design thus they can be quickly deployed and are less fatiguing for the operators, which leads to the faster completion of the project and the worksite safety becoming better.

How Vibratory Tampers Operate?

1. Mechanism and Design of the Vibratory Operator:

The operating concept of a vibratory tamper is essentially the transformation of mechanical energy into rapid vertical high-frequency blows that befit the compaction of soil strata.

The majority of such are normally equipped with either a two-stroke or a four-stroke internal combustion engine that powers the machine by rotating an eccentric weight inside it. The machine thus has a fixed point that the rotating weight is off balance and it generates centrifugal force which agitates the base plate very fast.

A spring mounting of the tamper’s base plate makes it possible for it to be briefly raised by each turn and then dropped hard, thus when it comes to the ground the striking action is delivered which compacts the bottom layer of the material. The forward movement of the machine is guaranteed by the angle of the housing that is always towards the ground allowing the operator to push the machine further across the area being worked on without manually changing the spot.

- Engine and Vibration System: In an installation of Honda or Kohler engines, vibratory tampers guarantee steady operation for a long period with the vibration frequencies being between 60 and 75 Hz thus the deep and even compaction are ensured.

- Spring-Loaded Base Plate Mechanism: The springs us pension between the base plate and the body allows the base plate to pull away after each impact, thus it accomplishes the jumping movement which not only improves compacting effectiveness but also lessens the operator’s fatigue.

- Forward Motion and Operator Control: The inclination of the cylinder brings about the pushing of the force to the front which consequently results in the normal easy flow of the surface being worked on while the person in control is able to keep the balance and be accurate at the same time.

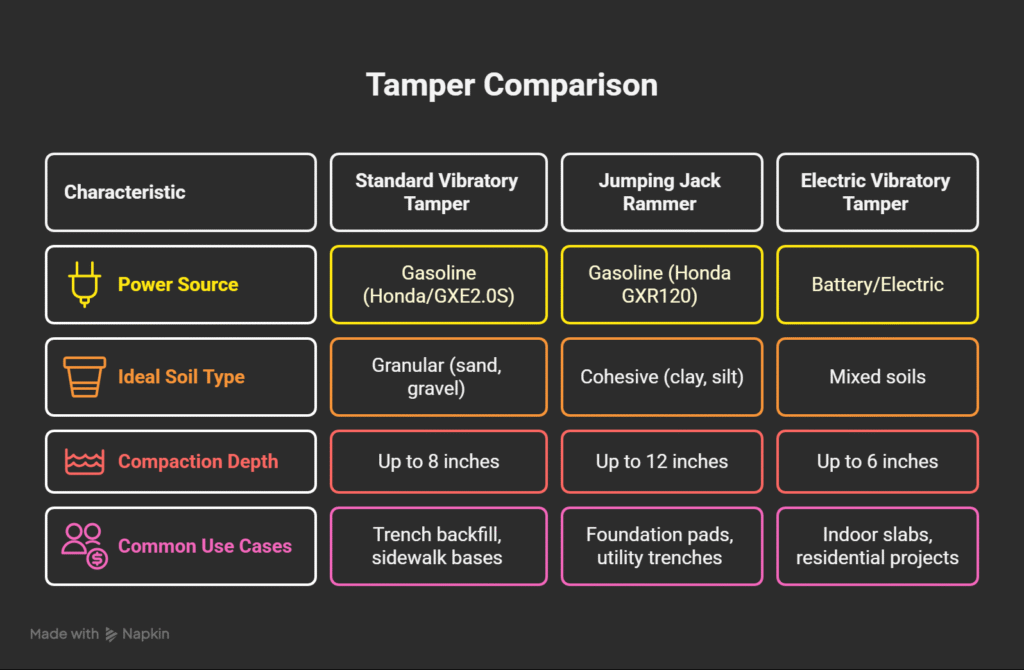

2. Variants of Vibratory Tampers and Their Use

One can buy vibratory tampers in different shapes and sizes that have been made with specific soil kinds and the nature of projects in mind. This thus gives the crews working on the road the freedom to make the right choice of which tool to use for which task. The main differences are between standard vibratory tampers and jumping jack rammers whereby each has certain advantages and which one to use is dependent on what the material is and how deep it has to be compacted.

For instance, standard ones are perfectly suited for loose earth and are able to make the surface compact up to a certain depth only, whereas the heavier ones with more power are fairly good for soils that tend to stick together and have a deeper layer. As a matter of fact, there are also electrically powered and battery-powered machines which are becoming green alternatives and are especially convenient in places where noise is undesired or indoor areas.

| Type | Power Source | Ideal Soil Type | Compaction Depth | Common Use Cases |

| Standard Vibratory Tamper | Gasoline (Honda/GXE2.0S) | Granular (sand, gravel) | Up to 8 inches | Trench backfill, sidewalk bases |

| Jumping Jack Rammer | Gasoline (Honda GXR120) | Cohesive (clay, silt) | Up to 12 inches | Foundation pads, utility trenches |

| Electric Vibratory Tamper | Battery/Electric | Mixed soils | Up to 6 inches | Indoor slabs, residential projects |

3. Key Benefits of Using Vibratory Tampers in Road Construction

Integrating vibratory tampers into road construction workflows delivers measurable advantages in terms of compaction quality, operational efficiency, and long-term infrastructure durability. These compact tools ensure that critical zones such as joints, edges, and utility cuttings are properly compacted, thus preventing weak spots that could undermine the entire pavement structure.

The portability of these machines is their great advantage in that they may be used over many different points of work with great speed thus the time between the end of one shift and the beginning of the next is reduced significantly, which results in the work rate going up. Apart from that, the fuel-efficient engines and low-emission technologies incorporated in the modern designs are compliant with environmental regulations and eco sustainability goals in the case of public infrastructure projects.

- Improved Compaction Uniformity: The use of vibratory tampers in hard-to-reach places allows the elimination of soil density inconsistencies which can eventually lead to structural failures.

- Cost and Time Efficiency: The faster compacting cycles and thus the fewer reworks that need to be done result in savings in labor and equipment costs over the time of the project.

- Durability and Low Maintenance: These tampers coupled with the robust components and simple mechanical systems are of minimal maintenance and long service life during hard use.

4. Best Practices for Operating Vibratory Tampers

One of the best ways to get the most out of the performance and at the same time ensure the safety of the operators is to adhere to the best practices established for the usage of vibratory tampers by the road crews on the sites where there are jobs. Being properly trained is a prerequisite for knowing the controls of the machine used, the techniques of compaction, and also being very much aware of the hazards involved.

At all times the operators must be attired in the personal protective equipment that comprises gloves, steel-toed boots, and hearing protection as the peak noise made during use is high. It is also a must that before starting the work the machine be inspected in advance to see whether there are enough fuel and air filters and to check the condition of the base plate.

The use of tampers during a shift must involve overlapping passes so that it can be assured that coverage is complete, and one should not stay in a certain place for too long so as not to cause the surface to be damaged.

- Operator Training and Safety Protocols: Comprehensive training programs diminish the probability of mishaps and consistency of compaction across teams gets better.

- Routine Maintenance and Inspection: Performing daily checks on engine oil, spark plugs, and vibration parts is an effective way of avoiding sudden breakdowns.

- Optimal Layer Thickness and Moisture Control: Accomplishing the task of compacting within thin layers (4–6 inches) that have the right moisture makes the density be at its highest level and rework is prevented.

5. Maintenance and Troubleshooting Tips

Carrying out regular maintenance is one of the major factors in prolonging the lifespan as well as the dependability of vibratory tampers. Some are the tasks that should be done after every usage and they comprise cleaning of the base plate and the undercarriage from the dirt that may cause the lowering of performance if it is built up.

Besides that, if the machine also has a hydraulic system, the user must always ensure that it is leak-free, and on top of that, according to the producer’s instruction, all the parts that are movable should be oiled. Issues such as irregular vibration and reduction in compaction power are usually due to the wearing of the bearings, the damage to the base plates, or engine defects.

Lowering the time when the machine is not working because of solving the problems it is facing by doing routine servicing is thus the solution to the problem when it comes to the prevention of the time of performance being interrupted.

Daily Cleaning and Inspection: Dirt and material buildup must be removed to keep vibration at its most efficient level.

Monitoring Vibration Performance: If there is a sudden change in the intensity of the vibration, this most probably points to the machine being internally damaged or out of balance.

Scheduled Servicing and Part Replacement: Keeping up with the manufacturer’s instructions in getting tune-ups and changing components is your ticket to avoiding expensive repairs.

Vibratory Tamper FAQs

What is the difference between a vibratory tamper and a plate compactor?

Vibratory tamper utilizes the help of a vertical impact force that is very suitable for deep compaction in narrow trenches whereas plate compactors apply horizontal vibration to be used in broader and shallower areas.

To what extent can a vibratory tamper compact?

Most of the models are capable of compacting up to 8–12 inches and the exact figure depends on the type of soil and the machine specifications.

Are the performance levels of electric vibratory tampers comparable to those of gas-powered ones?

Electric models can be used for light tasks and are suitable for indoor areas, but generally, they have less power than gas-powered variants.

What are the maintenance requirements of a vibratory tamper?

Confirming the condition of engine oil, air filters, spark plugs, and the base plate is very important in order to achieve the best performance and it should be done regularly.

Can vibratory tampers be used on asphalt?

They are less or not at all suitable for non-agricultural soil and granular materials, for which plate compactors are the better choice when it comes to asphalt.

Why is compaction necessary in road building?

The proper compaction is one that stops settlement from happening, increases the capability for bearing the load, and leads to longer pavement life.