Rollers are essential machinery in construction projects, used to achieve proper soil and surface compaction. Compaction enhances soil strength, stability, and load-bearing capacity, making the foundation suitable for roads, buildings, and other infrastructure. Selecting the right type of roller for the specific soil and project conditions is critical to achieving effective and efficient compaction. This detailed guide covers various types of rollers used for compaction, their features, applications, and the soils they are best suited for.

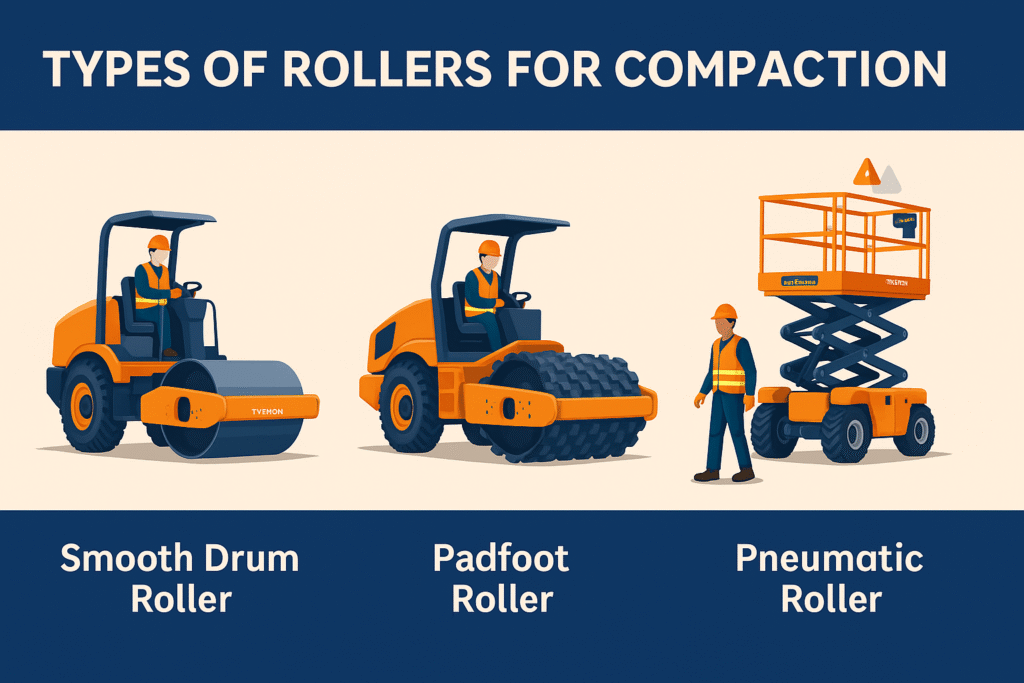

Types of Rollers for Compaction

-

Cylindrical Rollers

Cylindrical rollers are among the simplest types and are typically lightweight rollers made of iron, concrete, or stone. These are often manually operated or towed by animals or vehicles. Their size is usually about 1 meter in diameter and 1.5 meters long. These rollers generate a ground pressure around 7 kg/cm², making them suitable mainly for light compaction tasks on soil surfaces that do not require deep compaction. They are practical for small projects or initial soil leveling phases but are not ideal for heavy compaction needs due to their limited weight and pressure. -

Sheepsfoot (Padfoot) Rollers

Sheepsfoot rollers are easily recognizable by their heavy cylindrical drum covered with protruding round or rectangular “feet,” which provide a tamping effect. The feet penetrate into the soil, kneading and compressing it deeply, making these rollers ideal for cohesive soils such as heavy clays and silty clays. They are ineffective on loose, sandy soils because the feet tend to till rather than compress the material. Sheepsfoot rollers come in a variety of drum sizes and foot shapes, and the weight of the drum can be adjusted by filling it with water or sand to increase compaction pressure. Typical usage involves multiple passes (10 to 20) to achieve the desired soil density, and a finishing pass with a smooth roller is usually recommended for a smooth surface. -

Smooth-Wheeled Rollers

These rollers feature one or two large, smooth steel drums with no projections or feet. They are often self-propelled and come in single or double drum (tandem) configurations. Smooth-wheel rollers excel in compacting granular and mixed soils such as gravel, sand, crushed rock, and ballast. They exert uniform surface pressure and are commonly used in asphalt compaction on roads and parking lots to provide smooth finishes. While effective on surface layers and granular bases, they are less efficient for deep soil compaction due to lower ground pressure. Smooth-wheel rollers are critical for final surface work to achieve the required finish and smoothness. -

Pneumatic Tyred Rollers

Also called tire rollers, these feature multiple rubber tires mounted on axles instead of steel drums. The pneumatic tires provide a kneading action due to their elasticity, allowing for uniform compaction and better surface coverage. These rollers are ideal for compacting silty soils, asphalt pavements, and fine granular layers where some flexibility is needed to avoid over-compaction or damage to the surface. The load can be adjusted by changing tire pressure, and the rollers are effective for surface finishing, especially on road and pavement projects that require a polished, smooth finish. -

Vibratory Rollers

Vibratory rollers incorporate a vibration mechanism within the drum that oscillates the roller to create dynamic forces on the soil. This vibration significantly increases the efficiency and depth of compaction and is ideal for granular soils, crushed stone, and asphaltic concrete. Vibratory rollers can be single or double drum and are self-propelled, weighing typically between 4 to 12 tons. They compact deeper layers faster and more thoroughly than static rollers, reducing the number of passes required. These rollers are widely used for road base construction, embankments, and asphalt paving. -

Grid Rollers

Grid rollers have a cylindrical steel drum with a network-like pattern of steel bars forming square holes or openings. This design provides high contact pressure with limited kneading action, making them suitable for compacting coarse-grained soils like gravel and rocky subgrades. Often ballasted with concrete blocks, grid rollers are effective for large-area compaction work where high pressure is needed but without deep soil penetration. They are especially useful in subgrade preparation for highways and heavy-duty foundations. -

Walk-Behind Rollers

These are smaller, lightweight rollers designed for maneuverability in tight spaces such as landscaping, trench compaction, or small-scale projects. Walk-behind rollers may feature smooth or padded drums and typically weigh between 500 kg to 2 tons. Their compact size and ease of use make them suitable for situations where larger rollers cannot operate efficiently.

Application and Soil Type Suitability

- Cohesive Soils (Clays, Silty Clays): Sheepsfoot rollers are the most efficient due to their tamping action that kneads the sticky soils, breaking air pockets and aligning particles.

- Granular Soils (Sand, Gravel, Crushed Rock): Smooth-wheeled and vibratory rollers are preferred because they provide even, uniform compaction and can apply vibratory forces to settle particles densely.

- Asphalt and Pavement Layers: Smooth-wheel and pneumatic tyred rollers are ideal for finishing surfaces and providing smooth, even compaction without damaging the asphalt binder.

- Coarse, Rocky Soils: Grid rollers provide the necessary pressure to compact without dragging or digging into uneven gravel or rock bases.

Factors Influencing Roller Selection

- Soil Type: Determines the roller design and drum surface needed.

- Project Size and Reach: Larger projects may require heavy self-propelled rollers, while small or confined areas need walk-behind or cylindrical rollers.

- Compaction Depth: Vibratory rollers achieve deeper compaction; static rollers work better for surface densification.

- Weight and Ground Pressure: Heavier rollers exert more compaction force but may be unsuitable for delicate surfaces.

- Surface Finish Requirements: Smooth or pneumatic rollers are necessary for final surface layers to ensure uniform texture.

Conclusion

Understanding the different types of rollers for compaction and their respective applications helps in selecting the right equipment for any construction project. Sheepsfoot rollers are best for cohesive clays, smooth and vibratory rollers are suited for granular soils and asphalt finishes, pneumatic tyred rollers provide controlled kneading for silts and fine gravel, and grid rollers excel in coarse soil compaction. Proper roller selection based on soil conditions and project goals is vital for successful, durable compaction and construction outcomes.

This comprehensive knowledge equips project managers, contractors, and equipment specialists to maximize efficiency, cost-effectiveness, and quality in soil compaction tasks across diverse construction environments.