Unlock Sheepsfoot Roller Advantages!

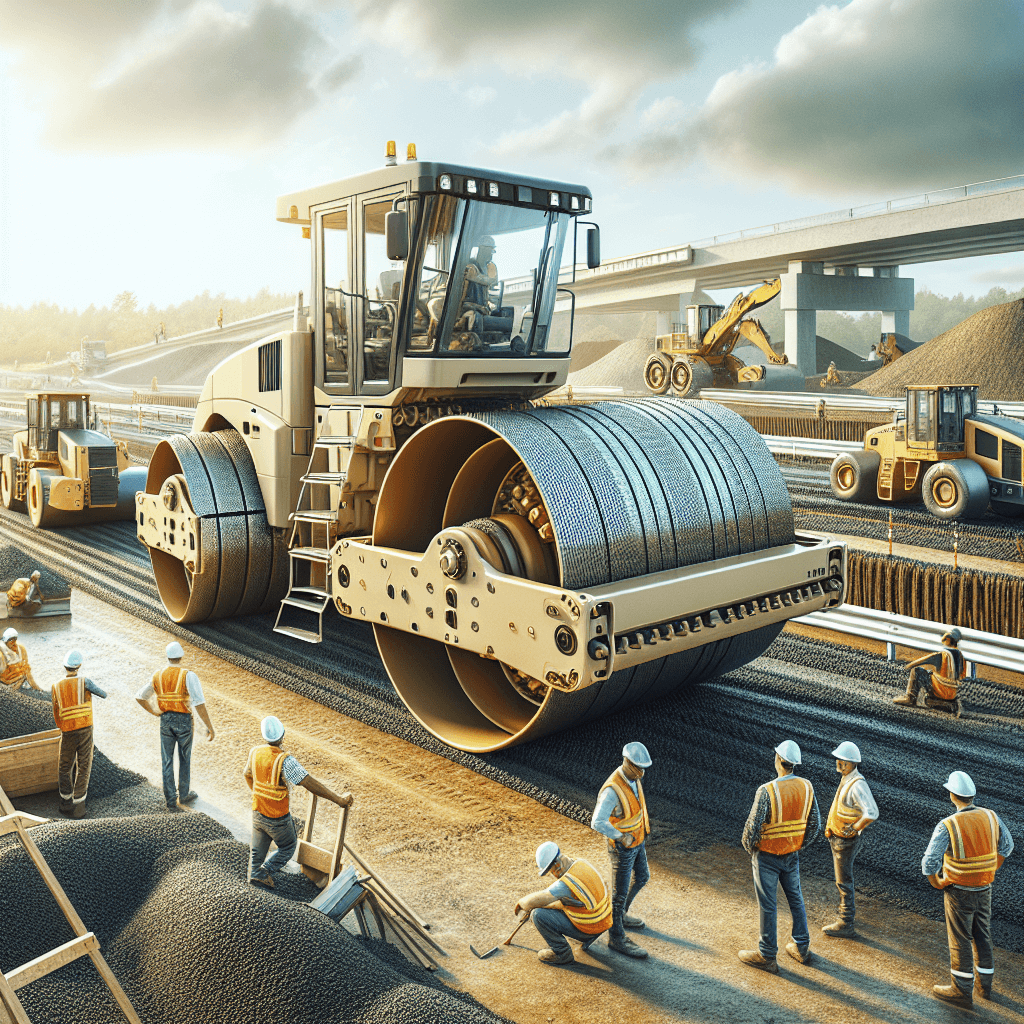

Importance of Sheepsfoot Roller advantages – One of the few machines that can perform and do it in a very efficient manner are those fine machines dealing with the so-called fine-grained soils (clay and silt) and, at the same time, the sheepsfoot roller compactor is one of them. Every project has sheepsfoot advantages of its own. This is distinguished by its singular projecting feet that not only agitates the soil but also fasten it in place.

Such a heavy-duty device has been garnering an ever-increasing popularity among the users which include the contractors, the engineers as well as the road construction professionals. In fact, the whole process of the earth having the right density is absolutely necessary if we contemplate a long life for foundations, highways, embankments, and large-scale infrastructure projects. And for that very job are the sheepsfoot rollers tailored.

In this manual, we are to denote various sheepsfoot roller advantages, the role of sheepsfoot rollers in clay and silt compaction, advanced usage techniques, and the reasons why they are so strong as to leave no room for their rivals in achieving optimal soil density.

Why Soil Compaction Matters in Construction

It makes good sense, first of all, to take a look into the reasons why soil compaction is such an indispensable step in the building process before enumerating the sheepsfoot rollers benefits. If proper compaction is not done, clay and silt soils will end up being reservoirs of moisture, and as a result, they will be subjected to weakening phenomena that will eventually lead to all sorts of breakdown scenarios in roads, pavements, and structural foundations.

Some of the reasons why soil compaction must be treated with the utmost care include the following:

- Improved Load-Bearing Capacity – Through compaction the air voids responsible for the low load-bearing capacity are minimized making the soil able to bear the loading without any sort of displacement taking place.

- Reduced Water Seepage – Soil permeability can be lowered substantially through good compaction. As a result, the probability of water intrusion that will weaken the base by coming from the soil is significantly reduced.

- Long-Term Durability – A properly compacted soil will limit settlement and consequently, lower the maintenance costs for the infrastructure.

In the case of clayey and silty soils, sheepsfoot roller advantages are undoubtedly the most effective compaction equipment as they are the only ones capable of kneading and disturbing fine-grained soils by their very nature.

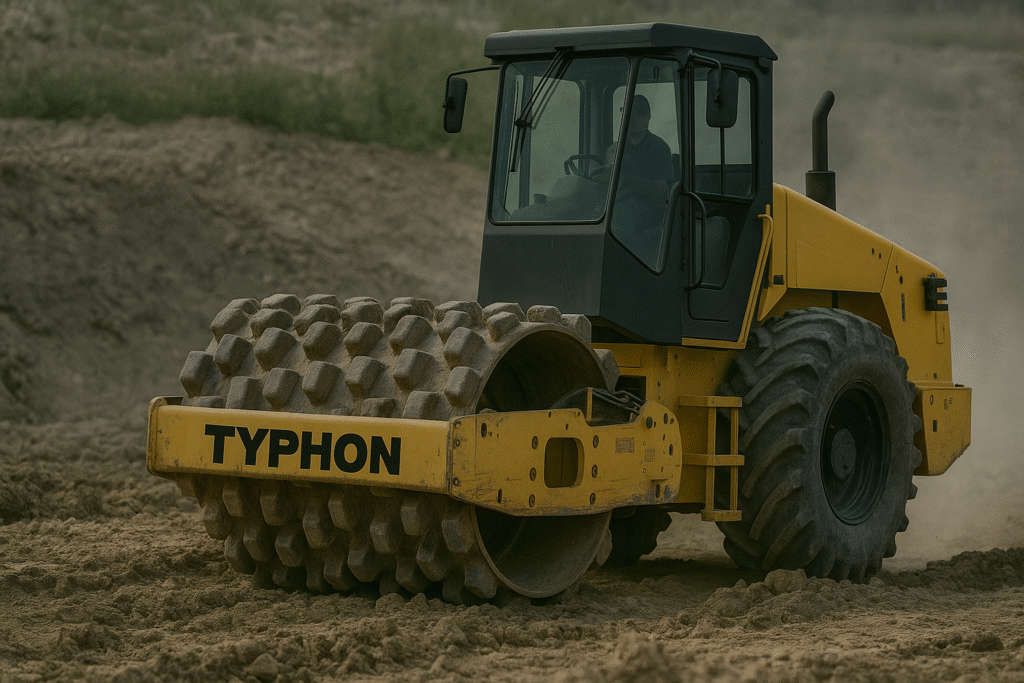

The Sheepsfoot Roller

The sheepsfoot roller or tamping roller, is a device consisting of steel drums equipped with rectangular or round lugs (feet). The feet put forward drill into the clay and the silt, thus they compact the soil from underneath the surface only which is not the case normally.

Core features:

- Projections Lugs (Feet) – Forged to work kneading and press fine-grained soils, thus raising the bonding between particles.

- Weight Drum – This will give enough pressure so that the densification of the deep soil can be achieved.

- High compaction activity – The machine can be also used along with vibration for more efficient soil treatment.

The concept is designed to ensure even compaction which is a must in works where soil and soft earth base strength are the main issues.

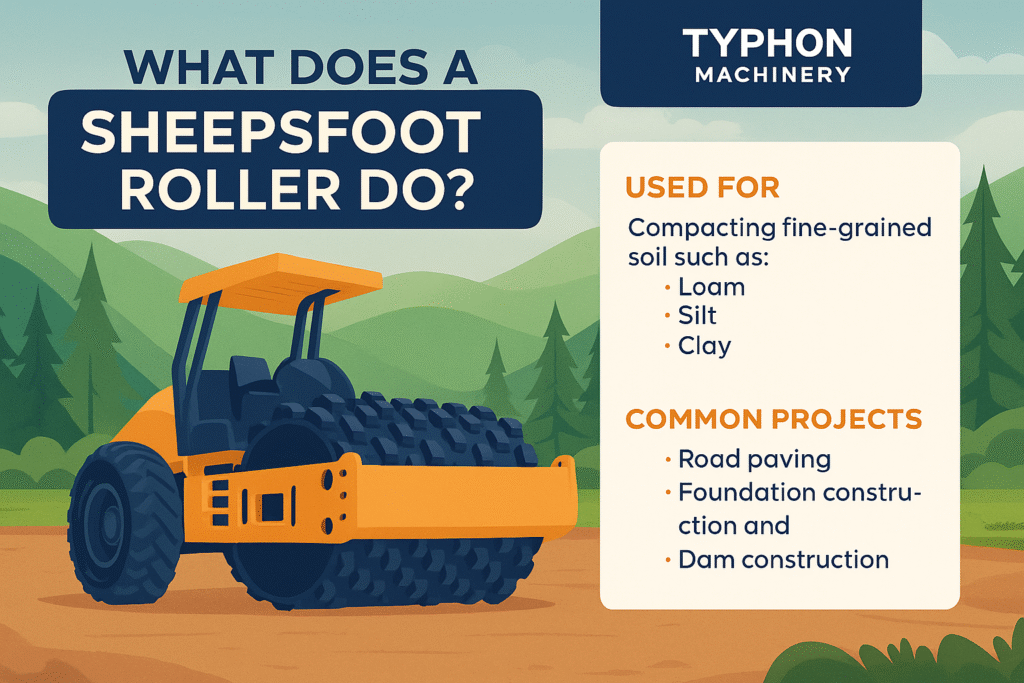

The Application of Sheepsfoot Roller in Clayey and Silty Soil

The main sheepsfoot roller advantages are the fact that they are very efficient in compacting fine-grained soils to the extent where even other rollers are helpless. Contrary to smooth drum rollers which are ideal for sand and gravel, sheepsfoot rollers are made with a purpose that is suitable for cohesive soils.

Main Sheepsfoot Roller advantages include:

- Superior Density in Cohesive Soils – As the kneading action is done, it cuts the voids and raises the levels of the compaction.

- Moisture Handling Capability – The machine works excellently in wet clay and silt, which are just a bit wet, whereas other rollers may fail or slip.

- Enhanced Soil Stability – It is designed to solve the problem of post-construction settlement in the area, thus the structures built are durable for a long time.

With the help of these sheepsfoot roller advantages, contractors are enabled to obtain uniform density not only on small-scale but also on large-scale construction projects that are clay or silt-based.

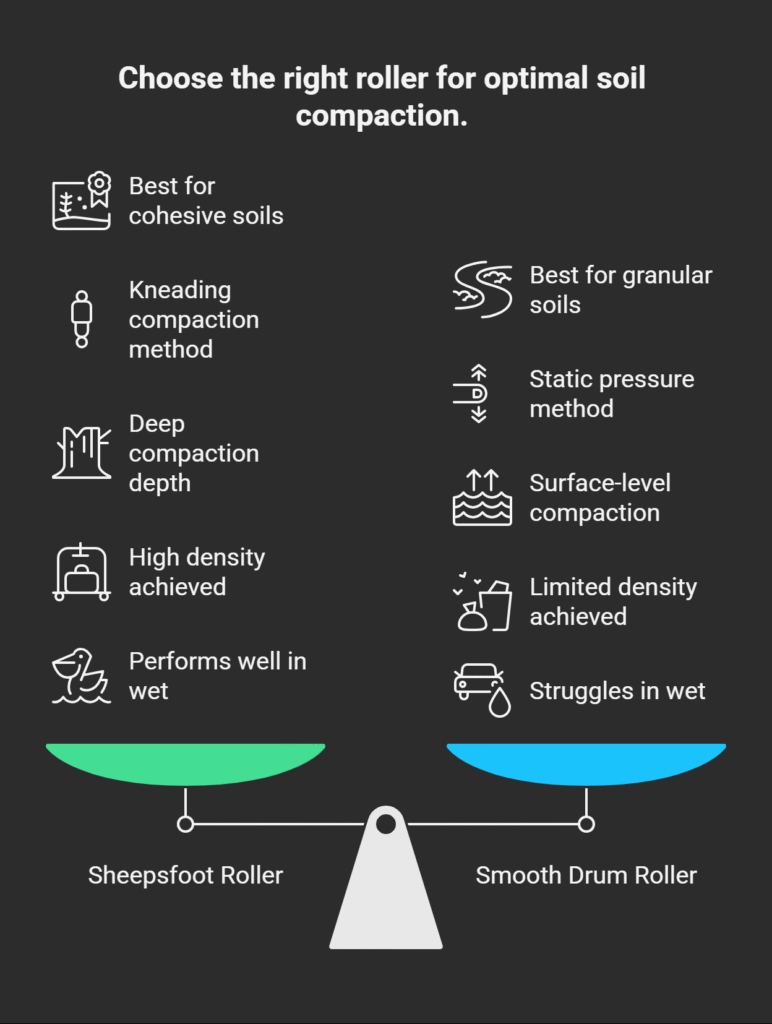

Sheepsfoot Roller vs. Smooth Drum Roller

Before making your decision between the two rollers, identify the soil type and then the project requirements. The below table summarizes the differences between sheepsfoot rollers and smooth drum rollers for clay and silt compaction.

| Feature | Sheepsfoot Roller | Smooth Drum Roller |

| Best Soil Type | Clay & Silt (Cohesive) | Sand & Gravel (Granular) |

| Compaction Method | Kneading & Pressure | Static Pressure & Vibration |

| Depth of Compaction | Deep (Bottom-Up) | Surface-Level |

| Density Achieved | High in cohesive soils | Limited in cohesive soils |

| Moisture Tolerance | Performs well in wet conditions | Struggles in wet cohesive soils |

Comparison takeaways:

Sheepsfoot rollers have the leading edge over smooth drum rollers in clay and silt compaction.

Smooth drum rollers are still functional to some degree with granular soils; however, they are not able to provide the same result when it comes to cohesive conditions.

Roller combinations are usually the preferred option of project managers when dealing with mixed soil projects.

Applications of Sheepsfoot Rollers in Infrastructure

Being sheepsfoot compactors of great versatility, they are virtually the only choice for long-distance infrastructure projects based on clay and silt, where the situation is changing every few kilometers.

Common applications:

- Road Embankments – Results in both stable and load-bearing road bases in clayey areas.

- Dams and Canals – Mixes fine soils tightly to avoid water seepage and weakening of the structure.

- Airport Runways – Is the source of uniform compaction for heavy load-bearing soil foundations.

- Railway Tracks – Is the main reason for soil stability, that consequently, enhances safe train rides when the tracks are laid over clay-rich regions.

As the projects abide by optimal soil density, the duration of the hardening process is shortened, and quality standards for works of this type are easily met by means of sheepsfoot rollers.

Best Practices for Using a Sheepsfoot Roller

With the intention of reaching optimal soil compaction and operating in the most efficient way, operators are required to strictly adhere to the sheepsfoot roller advantages have the best practices.

Key tips for effective usage:

- Adjust Moisture Content – Clay and silt are the best compacted when they are slightly moist. In addition, overly wet or dry soils will bring to the decrease of the compaction efficiency.

- Apply Adequate Passes – Multiple passes are the only way to assure that the uniform density is achieved. Thus one should go on until the roller feet no longer sink into the soil.

- Combine with Other Rollers – The use of sheepsfoot rollers followed by smooth drum rollers not only provides surface finishing but also ensures that the maximum density is achieved.

- Reduced Maintenance Costs – Proper compaction becomes the root cause of soil settlement and, consequently, repairs.

- Sustainable Soil Management – It meets the challenge of decreasing the consumption of soil-based chemicals.

- Time Efficiency – Less impasses are required if compared to the usage of equipment that is less efficient.

FAQs on Sheepsfoot Roller Advantages

Why is a sheepsfoot roller best for clay and silt compaction?

A sheepsfoot roller has feet that stick out and they dig into and compact the earth from the bottom, so it is no wonder that it is the best for cohesive soils like clay and silt.

How many passes are needed for effective sheepsfoot roller compaction?

The recommended number is usually 8–12 but in reality, the number depends on the moisture in the soil and the needs of a particular project.

Can a sheepsfoot roller be used on granular soils?

No, sheepsfoot rollers are not effective for loose sands and gravels. The hollow drum rollers with a smooth surface are designed to work better with granular soils.

What is the difference between a sheepsfoot roller and a tamping roller?

They are in fact the same machine. The term “Tamping roller” is merely one more name for the “Sheepsfoot roller”.

How does soil moisture affect sheepsfoot roller performance?

Only a little bit of water in the soil will show the best compaction result. If the roller is put for work on a very wet or very dry soil, it won’t work as it should.

Are sheepsfoot rollers cost-effective for large projects?

Of course, with the help of sheepsfoot rollers, the desired density could be reached in less time and the cost for the maintenance of the equipment will be lowered in the long run.

Can sheepsfoot rollers achieve 100% Proctor density?

They are very successful but on many occasions smooth drum rollers are also used to get the final Proctor density and to make the surface even.

Sheepsfoot Roller Advantages Summary:

The Sheepsfoot roller compactor is the best option to get the maximum density of clay and silt soil as it compact these soils by its unique design and kneading action which enable deep and uniform soil density to be achieved.

No other rollers can accomplish such sheepsfoot roller advantages as deep and even density for cohesive soils. By leveraging its advantages, applications, and best practices, contractors can instill ground stability for a longer period of time, cut down on the maintenance costs, and get higher project outcomes.

For road construction, embankments, dams, and heavy infrastructure projects, the sheepsfoot roller compactor is the topmost choice to achieve the maximum density of clay and silty soil.