A sheepsfoot roller, or a padfoot or tamping roller, is one of the most prominent types of compaction equipment. Sheepsfoot rollers are those designed to compact a material, e.g., soil, silt, and clay, before building roads and foundations.

Sheepsfoot compactors are made with different specs, e.g., weight, drum width, horsepower, length and number of feet, maneuverability, and gradeability. With so many types of rollers to consider, this post breaks down the benefits of sheepsfoot rollers and how they compare to other options.

How do Sheepsfoot Rollers Work?

Sheepsfoot rollers are available as ride-on and pull-behind models that can be towed by a tractor or a dozer. In the static versions, the compaction is done by the heavy drum while the soil is manipulated by the feet. Vibratory models employ the weight and feet, as well as dynamic compaction. Hence they are generally faster in compaction than static ones.

The mechanical force that comes from the tapered lugs, or “feet,” enables the drum to compress the ground to deeper layers and mix the soil. For this reason, sheepsfoot rollers are typically used to compact clays or silts.

If you are getting a sheepsfoot roller for your project, the soil type, thickness, moisture content and job size will tell you what size of the sheepsfoot roller will be right for you. Some drums might be filled with water or sand to make them heavier.

Single-drum Roller

One of two main types of rollers, each of which is designed for diverse construction needs. The choice of the right compaction equipment heavily relies on factors such as the size and range of your job site, the nature of the ground, and the outcome you desire.

Double-drum Roller

A double-drum roller is the other main type of roller. The double-drum roller has two drums, one in the front and one in the back, which means it can compact twice as much. It doesn’t have any tires because the drums work as wheels.

When you drive a double-drum roller over anything, you compact it twice. The double-drum roller is more powerful, but it can’t move or climb as well because it doesn’t have tires. It works well on wide, flat job sites including roads, pathways, playgrounds, and parking lots.

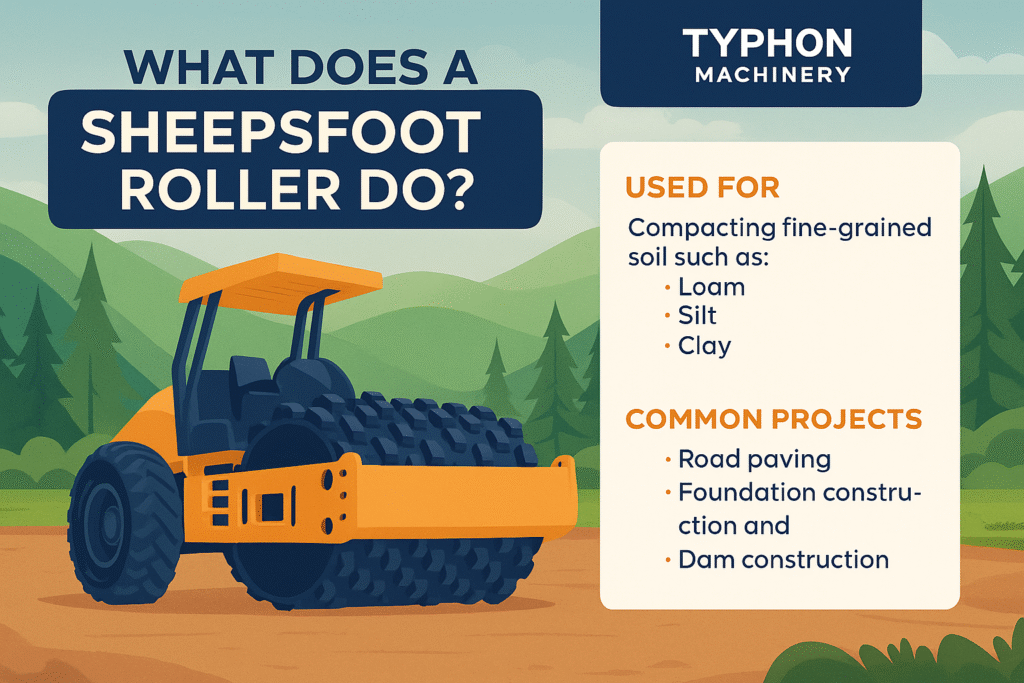

Sheepsfoot Roller Uses

A sheepsfoot roller works best for projects that need deeper compaction. It is commonly used to compact silty clay, wet clay, and other cohesive soils.

Use a sheepsfoot roller for projects like:

- Road construction work

- Dams

- Embankments

- Foundation construction

- Ponds

Pros and Cons of Sheepsfoot Rollers

The sheepsfoot compactor has a unique design that makes it better for specific jobs than other types of rollers, even though it isn’t great for every job. When you rent a roller for your next job, think about the pros and cons of employing a sheepsfoot roller:

Pros

- Depth of compaction: The sheepsfoot roller compacts at deeper levels than a smooth drum roller because of its “feet.”

- Compaction is flexible: Sheepsfoot rollers can be used as both static and vibratory rollers, so they can handle a variety of terrains and materials.

- Material: The sheepsfoot roller can operate with cohesive soils, which are soils that are fine-grained or have a lot of clay in them. Other rollers can’t do this.

- Speed of compaction: The drum and “feet” of sheepsfoot rollers work together to compact materials faster.

The sheepsfoot roller is very easy to move around and can work in tight, small, or deep locations.

Cons

- Evenness of compaction: The sheepsfoot roller may not make the surface as smooth as a smooth drum roller because of its “feet.”

- Material: Sheepsfoot rollers don’t work well on sandy or loose materials because the “feet” of the padfoot drum tend to till them instead of compacting them.

- Size: Sheepsfoot rollers are small, thus they don’t work as well for covering a broad area.

Sheepsfoot Rollers vs. Other Rollers

You may rent a lot of various kinds of rollers besides the padfoot roller. Each one is made for a particular type of building work. The kind of compaction equipment you require depends on the size and breadth of your job site, what the ground is built of, and what you want to happen.

Sheepsfoot Roller

The sheepsfoot roller drum, the “feet” that are on the drum, help it to compact the ground at other depths, and this roller gives you great maneuverability if you are required to fill trenches at a narrow spot. To make compacting even more effective, you can add the sheepsfoot drum. Such as clay, silt, and loam, the roller works best when cohesive soils are present in the ground of your job site.

Smooth Roller

You can choose either a single-drum or double-drum option with the versatile smooth drum roller. Both work great in projects that require leveling the ground, and produce an even, flat terrain. If the area of your project is made up of granular materials, like sand, ballast, and gravel, a smooth drum roller probably makes the best option.

Use a single-drum roller for smaller projects, like driveways and sidewalks. Use a double-drum roller for larger, lengthier areas, like roads and parking lots, especially if the project contains limestone.

Vibratory Roller

A vibratory roller is nearly similar to a smooth roller. However, it operates in a way that it vibrates, combining static and dynamic forces to raise the compaction capacity. The vibrations achieve an increment in density of the soil to the point that the structural integrity of the foundation is helped. The weighted design of vibratory compactors makes them the best choice for work on slopes or with materials like gravel.

Pneumatic Tyred Roller

The pneumatic tired roller is unlike other compaction equipment in that the front and/or rear end of it is equipped with rows of rubber tires instead of a drum. The tires are the ones that evenly apply pressure to ground surfaces, thus, it being easier to achieve uniform compaction over a job site.

Its reach in terms of depth is very limited as compared to a padfoot roller; therefore, it is relegated to the later stages of a project, where it can be used to smooth out or polish. This roller is mostly used with materials like cold-laid asphalt.

Grid Roller

The grid roller is actually a single-drum roller that has the heavy drum made from the steel bars, which are in the form of a grid. The size and the toughness of the drum are the reasons why the roller can make deep compaction without even needing more power. The grid roller, which is commonly towed behind a tractor or a big machine, is the tool that you can rely on to work on difficult, hard materials such as coarse soil and weathered rock and break up tough terrain.

Cylindrical Roller

The cylindrical roller, in contrast to the other types of rollers, is not a heavy soil compaction machine. It is a lightweight and manually-operated device that offers minimum soil compaction. Generally, it is a person who walks behind this soil compactor and it is perfect for small-scale works such as yard works.

Conclusion

In accordance with the size and range of your worksite as well as the materials dealt with, one compactor can serve your needs better than another. Sheepsfoot roller is an excellent selection to get you deeper compaction especially when you deal with cohesive soils like heavy clay or silt or work in narrow and tight spaces. A smooth drum roller is a perfect choice to get a uniform polished finish.