As 2025 infrastructure and landscaping demands rise, roller compactors, once just simple roadwork tools, have changed and now offer more capabilities. A roller compactor, assisted by some attachments, will be a multi-skilled machine, and you will be able to use it for various job sites thus saving time, money, and effort.

Whether you are involved in construction, road maintenance, or landscaping, the mentioned attachments will also improve functionality, efficiency, and the life of the machine.

In our write-up, we will present you top 6 must-have roller compactor attachments in 2025 with detailed descriptions of their benefits, and the reasons why they are important. Let’s get started!

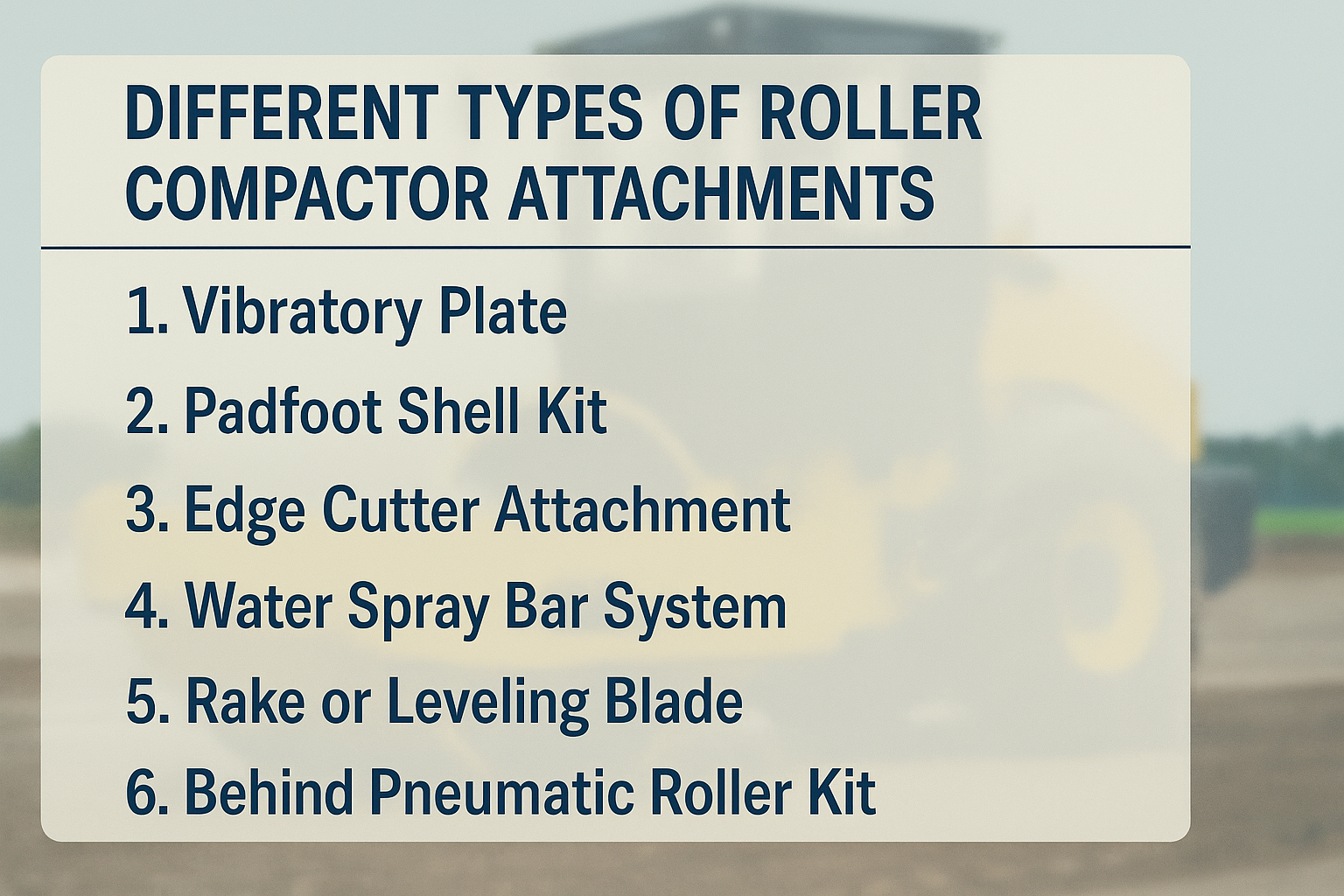

1. Vibratory Plate Attachment – Boosting Compaction Power

The vibratory plate is a game-changer when it comes to increasing the force of compaction. In 2025, this attachment has become smarter and more energy-efficient. It works by using rapid vibrations to reduce air gaps in soil, asphalt, and gravel—ensuring a smoother and more stable surface.

Why is a vibratory plate attachment necessary:

- Higher Levels of Compaction: Faster, with less traffic and less fuel usage, deeper or more effective compaction is achieved.

- Lower Supplies Costs: Through the even distribution of the load, the roller gets little pressure, thereby using less power and eventually ensuring increased maintenance span.

- Multi-Surface Tread: Not only to hard mounds but also for cohesive terrains, granular quarry products as well as to mixed lanes, the vibratory plate fits the job.

- Optimal for Tight Spaces: It is particularly useful for the edges of curbs, digging trenches, and working on smaller construction areas.

The following are the features which are the best fits for areas with limited space: It is preferable to apply them on the edges of the sidewalks, in between trenches, or other relatively small areas of construction works.

| Feature | Benefit |

| High-frequency vibration | Deeper and faster soil settling |

| Modular design | Easy attachment and removal |

| Reinforced steel construction | Long-lasting durability |

| Vibration control system | Reduced operator fatigue |

2. Padfoot Shell Kit – Ideal for Cohesive Soils

Padfoot drum shell kits are the most efficient when operating in a cohesive soil working condition. Diverse and heavy clay soils can transform the drum shell designs into a smooth drum that can easily be used for the compaction of trenches or landfills. In 2025, the design has been enhanced with increased interlocking grooves for better soil consolidation and better productivity.

Why It’s Essential:

- Improved Traction: The padfoot structure grips and kneads sticky soils better than smooth rollers.

- Increased Density: Helps compact high-moisture soils without sticking or slippage.

- Multi-Application Use: Great for site preparation, landfills, pipelines, and foundations.

- Cost-Efficient Adaptability: Eliminates the need for buying a separate padfoot roller.

| Padfoot Attachment Specs | Details |

| Tooth depth | 4 to 6 inches |

| Coverage width | 54″ to 84″ (varies by model) |

| Steel hardness | Hardened high-carbon steel |

| Compatibility | Fits most smooth-drum rollers |

3. Edge Cutter Attachment – Precision Asphalt Trimming

In the construction of highways, neat and sharp edges play a significant role. The edge cutter attachment ensures accurate trimming, helping you achieve a professional finish and prevent surface cracks. This is one of the leading roller compactor attachments that are getting popular in 2025.

Reasons Why It’s Essential:

- Clean Asphalt Cuts: Allows perfect edge trimming for new or repaired asphalt patches.

- Improved Surface Bonding: Clean cuts enable better sealing and bonding between old and new layers.

- Adjustable Cutting Width: Easily customizable to suit project requirements.

- Increased Safety: Prevents damage to curbs and prevents uncontrolled cracking.

| Edge Cutter Features | Benefits |

| Hydraulic or manual control | Flexible operation |

| Replaceable cutting disc | Long-term usability |

| Angle-adjustable blade | Custom edge profiles |

| Works with all compactor types | Universal fitting available |

4. Water Spray Bar System – Dust Suppression & Smooth Finish

Dust and debris can be a major contributor to decreasing the compaction efficiency. One of the more advanced and practical tools is the water spray bar to be fitted on the roller. In addition to better performance, sustainability plays a key role in the machine’s success.

The water spray bar is indeed the most important tool for environmental safety and a smooth finish for the surface in 2025. The new dust suppression and cooling system can spray the water in a very thin layer which can surpass the dust and clean the droops at the same time.

Why It’s Essential:

- Dust Control: Limits dust generation for site workers through cleaner development practices.

- Drum Cooling: Avoids the sticking of asphalt on the drum, virtually creating a smooth work area.

- Even Surface Finish: By keeping constant pressure perpendicular to the keyboard, the surface remains flat.

- Eco-Friendly: Low water consumption is used to maximize the dust suppression effect.

| Spray Bar System | Key Benefits |

| Corrosion-resistant tanks | Long-lasting operation |

| Auto-timer sprayers | Water-saving efficiency |

| Multi-nozzle design | Even water distribution |

| Fits front or rear drums | Flexible mounting options |

5. Rake or Leveling Blade – Site Preparation & Finishing

With the help of the rake or grade blade, your compactor can be easily transformed into a site preparation tool. This period of time is definitely the age of landscaping; the most wanted equipment will be the roller compactor with a rake or a grade blade to carry out various tasks, such as packing gravel drives, shaping sub-bases during construction, and final grading for both residential and commercial zones.

Why It’s Essential:

- Multi-Tasking Capability: This blade is used to grade and compact one go at a time, which is perfect for the fast project cycles of the company.

- Landscape Ready: It is a highly productive implement for making level pads, walkways, and sloped areas.

- Hydraulic Control: The very fact that different blade angles can be chosen to fit just the right form of it shows us that the blade can be tailored to the specific needs of the endeavor.

- Cost Saving: The most significant benefit that it offers over other methods is that it does not require additional grading equipment for the process and hence human labor is not required for the work.

| Blade Specs | Details |

| Width | 60″ to 84″ |

| Tilt Range | 0–45 degrees |

| Blade Type | Serrated or smooth |

| Mount Type | Bolt-on/hydraulic mount |

6. Behind Pneumatic Roller Kit – Enhanced Surface Bonding

The new entry for this year is gaining attention for its functionality that enhances asphalt compaction by improving surface bonding. This tow-behind equipment utilizes rubber tires to press uniformly around while it follows mostly vibratory compactors to get a much better finish.

Why It’s Essential:

- Uniform Pressure Application: The paver can be used to run over the entire surface of the material and provide a smooth compacted surface to achieve the sealing of the surface.

- High-Speed Operation: Being towed behind the vehicle is the significant attribute of its high-speed function.

- Surface Sealing: It is one of the important parts of the paving process, which smooths the surface and makes it impervious to rainfall.

- Enhanced Load Distribution: Reduces markings on the track and sections that are too compacted.

| Pneumatic Roller Kit | Advantages |

| 6–9 pneumatic tires | Smooth finish |

| Adjustable weight loading | Controlled pressure |

| Rubber tread surface | No scuffing or marking |

| Universal hitch | Compatible with most rollers |

Summary Table: Quick Comparison of Top 6 Roller Compactor Attachments

Here is a quick peak into the summary of the prominent attachments for Roller Compactors.

| Attachment Name | Best For | Key Benefits | Estimated Cost (2025) |

| Vibratory Plate | Deep compaction | Faster, deeper compaction | $2,500–$5,000 |

| Padfoot Shell Kit | Clay/Sticky Soils | Interlocking soil kneading | $3,000–$6,000 |

| Edge Cutter | Asphalt finish | Sharp trimming | $1,500–$3,500 |

| Water Spray Bar | Dust control | Clean finish, safety | $800–$2,000 |

| Leveling Blade | Site grading | Dual-purpose use | $2,000–$4,000 |

| Pneumatic Roller Kit | Surface finish | Smooth, sealed layers | $4,000–$7,500 |

FAQs About Roller Compactor Attachments

Which attachment is best for road repair in urban areas?

The edge cutter and vibratory plate because of their very precise and compact performance are just what you need.

Can I attach a leveling blade to any roller compactor?

Modern compactors are the ones that support rake attachments with hydraulic or manual mounting brackets, but be sure to check the compactor’s compatibility with the respective attachments before obtaining them.

Are water spray systems mandatory for asphalt compaction?

The use of such systems is optional, albeit they are highly recommended due to their ability to provide a smoother and faster finish, prevent the mixture from sticking, and comply with the dust regulations of the National Environment Commission.

How often should I replace padfoot shell teeth?

Change the teeth after 500 – 800 hours of use or when the wear limit is exceeded by 30%.5.

What size vibratory plate should I choose?

The plate should be chosen in accordance with the roller width; the best option is the plate which matches the drum width or it may be slightly wider for the purpose of a uniform performance.

Do attachments affect compactor warranty?

No, as long as original equipment manufacturer (OEM) or certified aftermarket parts are employed; nevertheless, talking to the maker before using the device is crucial.

Can I use multiple attachments at once?

In general, no—it is not possible to use multiple attachments at once because each of them needs their respective rollers, but there are a few exceptions such as the spray bar and edge cutter that can work simultaneously.