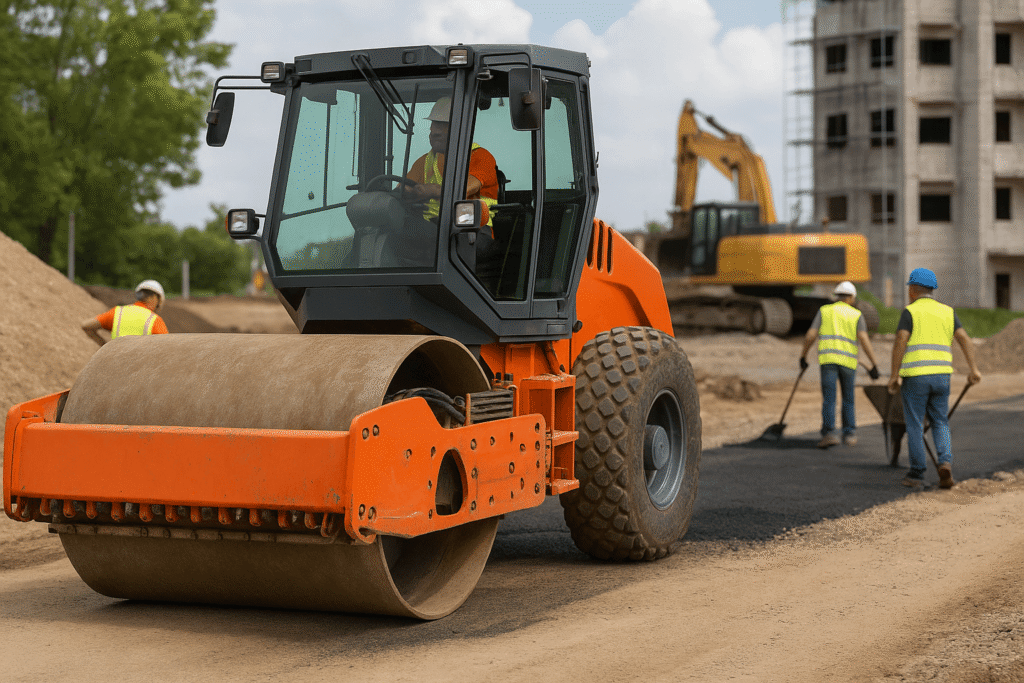

Roller Compactors: Essential Uses and Benefits Explained: Roller compactors are taking the construction and landscaping industry by storm, as they are not simply heavy machinery anymore; they are also the most sought-after innovative tools. Due to their sturdy design, these machines are not only used to smooth the ground but also to prepare it for extraordinary results by enhancing comfort, strength, and long-term performance.

Whether you’re constructing a road, preparing a walkway for a garden, or even condensing the ground of a backyard for a new patio, roller compactors are there to afford the unmatched precision and efficiency to your project.

Roller Compactors: Essential Uses and Benefits Explained

The fact that they can be used in a number of projects makes them indispensable for people who are working independently and therefore, they become a multipurpose tool. By using the power of roller compactors, you have not only accomplished the integrity of your surfaces but have also overhauled your workflow system and reduced the rework time.

In the discussion below, we will uncover the practical benefits of roller compactors beyond the theoretical and demo stage and help you see yourself how they can make your future projects easier- this is no puns intended, sans figuratively or literally.

Understanding How Roller Compactors Work

One of the key features of a roller compactor is its ability to make the soil, gravel, asphalt, and other materials it covers not only be compressed but also solidified and stabilized. This shall be brought about through the use of a mass of raw, vibrating, and mechanical equipment.

What we mean by the main component is a sizable, heavy drum which is rolled over the substance to be compacted. The mere weight of the drum is often more than enough to assure a good compaction level, however, the majority of the present-day machines are equipped with the latest vibrational features.

Roller compactors can be driven by a number of means such as diesel engines, hydraulic systems, or even manpower in smaller models. The operator is the one operating the machine, making it run through the ground and pressing the material down to achieve an even compaction.

The roller can be made to rotate at the speed and frequency of the drum’s oscillations that is convenient in order to compact certain materials and do the work necessary. It is this feature that makes roller compactors so versatile and in demand.

One of the most fundamental principles that lie behind the roller compaction technique is that it works by transforming mechanical energy into the ground. During the process, the downward force, the drum exerts while moving over the material, crushes the particles together.

In addition to this, compaction also causes the material to become more dense, which results in an increased load-bearing capacity as well as the whole structure’s stability. Compacted surfaces do not wobble; the voids are no longer there, and the structure is not as fragile as before. Roller compactors are crucial in the construction and building industries because they guarantee excellent compaction.

Key Benefits of Using Roller Compactors

One of the most important reasons to use roller compactors is that they can increase the efficiency of construction and landscaping projects. By doing the work rapidly and efficiently, these machines significantly reduce the amount of time and labor compared to the manual means.

Such efficiency, in turn, saves a lot of money, as more projects can be completed in a short time and with few resources. Besides the great degree of compaction the machine can attain, which reduces the chance of rejection of surfaces, project costs will also be lowered.

1. Enhanced Soil and Surface Stability

Roller compactors significantly increase the density of soil, gravel, or asphalt, providing a solid, stable foundation that prevents shifting, cracking, and erosion over time.

2. Improved Load-Bearing Capacity

By compressing the ground material, roller compactors improve the surface’s ability to support heavy loads—crucial for roads, parking lots, and large infrastructure projects.

3. Increased Project Efficiency

With their powerful compaction capabilities, roller compactors reduce the number of passes needed to achieve optimal results, saving time, labor, and fuel.

4. Long-Term Durability of Structures

Properly compacted surfaces resist weathering, settlement, and wear better over time, reducing maintenance costs and extending the life of roads, pavements, and landscaping features.

5. Versatility Across Applications

Roller compactors are suitable for a wide range of projects, from roadwork and building foundations to landscaping, driveways, and sports fields.

6. Uniform Compaction

These machines provide consistent pressure over wide areas, ensuring even compaction and eliminating weak spots that can cause structural failures later.

7. Cost Savings Over Time

Although the initial investment may be significant, the reduction in material wastage, labor hours, and repair needs delivers long-term cost benefits.

8. Environmentally Friendly Outcomes

By achieving proper compaction, roller compactors help minimize water runoff and soil erosion, promoting eco-friendly land development.

9. Easy to Operate with Minimal Training

Modern roller compactors come with user-friendly controls and safety features, allowing operators to quickly become proficient and work safely.

10. Adaptable to Any Project Size

Whether you’re managing a large commercial build or a backyard landscaping job, there’s a roller compactor model to suit your scale and needs.

Roller Compactors in Construction

When it comes to constructing roads, a proper understanding of roller compactors is a must. It is a must-have tool for compacting the soil during the construction of the roads, which makes the earth and gravel base solid and compacted, and after that, the asphalt or concrete can be applied.

The process is important for the future of the road because it helps avoid possible damages to the road surface, like potholes and cracks, if carried out properly. Roller compactors are indeed the most involved instruments for compacting asphalt or concrete, which serves the smooth and long-lasting surface to the high-pressure vehicle load.

Roller compactors are as well pivotal in the construction of building foundations. The foundation that has been well compacted is very essential to the stability of any building structure, as it prevents the surface from settling and the structure from shifting over time, which can result in destruction.

Through the process of compaction with the assistance of roller compactors, below the foundation of the ground, a strong ground that can hold a structure’s weight is formed. The compaction is noted in its particular significance in unstable or highly variable soil areas where the right compaction becomes the main way to prevent subsidence and similar problems.

Another application of roller compactors apart from construction is in the smaller fields of gardening and landscaping. When carried out properly, the machines can be very handy and efficient in such ventures. For instance, they can be used to prepare the ground first for the patio, pathways, and other hardscaping features, making it level and stable.

Additionally, this machine will help in the preparation of seedbeds for the home gardener as compacted soil provides the roots of the crops with adequate support and prevents water evaporation. This is the reason why symmetric compactors are versatile and are used in various projects from large constructions to home renovations.

Types of Roller Compactors: A Comprehensive Overview

There are different types of roller compactors for specific applications and materials. Mostly, they are designed for certain components in different types of roads and various types of work they are involved in at a given time.

The standard used in all road construction is the smooth drum roller, which is capable of covering the granular materials like sand and gravel for compaction purposes.

This kind of compactor is a heavy machine that has a flat and smooth wheel. Smooth drum rollers can be vibratory or static, the vibrating ones add the extra compaction force which the rollers of the other type lack. These types of rollers are extensively used in road construction or any project that requires a very smooth and level surface.

Padfoot, or sheepsfoot, is another remarkable type of roller compactor. These machines are equipped with a drum attached to pads or “feet” that have the ability to penetrate the ground and further compact it. In more detail, the padfoot rollers are only meant to compact the cohesive soils, indeed, the pads are the reason clay that already requires a larger amount of compaction can be kneaded and loosened up for thorough treatment.

The compaction of the soil by rolle is not always the same, and changing environments along the very soil always happen as a result of human activities whereby constructions that even extends to the sky are done every day. These machines are also used in most of earthwork projects such as the construction of embankments, building of dams, etc.

Pneumatic rollers, which are suitable for the jobs that require the combination of smooth and kneading compaction, have rubber tires to move around. The rubber tires carry the load and move the machine forward. that provide Kneading-combined rollers take out a large part of the immune system, leaving whatever is there to die.

These machines serve the purpose of compacting materials that are in a plastic state and can also be used to crush adhesive materials; thus, the machines are multidimensional. To be more specific, they are also capable of increasing the sediment concentration during the mixing of sand and gravel. They are, therefore, suitable for use in a variety of construction and landscaping applications.

List of Suitable Roller Compactors for Different Types of Construction Jobs and Projects

In choosing an effective roller compactor for your project, you should consider the material to be compacted and its characteristics (sand, clay, etc), the size of the area to be compacted, and the number of passes required throughout the construction.

Generally, when it’s about granular materials like sand and gravel, a smooth drum roller is the best fit, mainly because they offer equal compaction and form a smooth surface after the job is done.

However, compaction with pad-footed rollers is the most suitable for cohesive soils such as clay, as the feet can penetrate and, at the same time, knead the material to make it take up the remaining space.

The area’s size to be compacted is one of the primary concerns to be determined. Whatever the large construction projects like building roads or the installation of foundations for buildings, the most powerful and most efficient roller compactor is a must. These machines do the job very fast and can also be relied on for effective compaction for immense tasks.

A project like gardening or landscaping, for example, would require a smaller roller compactor, which is more than enough. In this case, the machines are quite handy and lightweight and yet they are giving enough compaction to the less exacting work.

Another deciding factor in defining the proper roller compactor is the extent of the desired compaction. A wide range of constructions, such as the case of road bases and building foundations that require the highest possible compaction level, would opt for a vibratory roller.

These machines use the vibration to offer additional force that compacts and also enhances the entire compaction process, leading to an even spread of compaction. On the other hand, a static roller could also suit the purpose, to fulfill the compacting requirements without causing any disturbance or vibrations to the surroundings, hence without the need of vibrations.

Roller Compactor Maintenance Tips

Ensuring that the life and performance of roller compactors are well-preserved is contingent on people performing regular maintenance on them. To keep the compactors in working condition, the users should conduct regular tasks such as changing the oil, checking/replacing filters, and making sure that all moving parts are well-lubricated. Engineers around the world.

The first aspect that needs to be taken care of is to periodically scrutinize both the drum and other machine parts for damages and if there is any foul play then those errors should be nipped in the bud. The above-mentioned checks and supervision of defects are some of the means of extending the machine’s life.

As well as regular upkeep, it is crucial to stick to the manufacturer’s instructions for operating and maintaining your machine. This covers the use of the right type of fuel and lubricants, the operation of the machine in its specified condition, and following the normal inspection and maintenance duties as recommended. Adhering to these requirements is key to the machine’s performance efficiency and safety being upheld; hence, the associated risks of accidents and breakdowns are minimized.

The correct storage of the roller compactors holds the next key to proper and efficient maintenance and care. Aside from the usual maintenance of the roller compactors, storage is one vital part of the whole process of maintaining its good condition.

The machine has to be kept in a proper and perfectly clean, dry, and secure place to avoid any theft-related or environmental damage. In this regard, doing the required maintenance tasks like drum and other parts cleaning, fuel system draining, and moving parts lubricating is the best way to avoid the machine to be subjected to corrosion and other damages while in storage and to keep it ready for use.

Safety Measures for Roller Compactors Operators

Security takes the number one position when it comes to the operation of roller compactors, as it is a fact that these machines are very powerful and thus can be very dangerous if used in the wrong way. The correctly educated and trained operators will thus be the ones who will run these rollers safely, knowing the basic operations, potential hazards, and emergency procedures.

This involves knowing the starting and stopping of the machine, safe operation, and how to avoid any hazards. In addition to this, they must have an appropriate personal protective equipment, such as helmets, goggles, and ear covers, sufficient to keep them safe from injuries.

When using roller compactors, it’s absolutely critical to observe safety rules and make sure the surrounding area is free from obstacles and hazards. The process involves checking the ground for the presence of underground utilities such as gas and water lines and making sure that the surface is stable and devoid of debris.

In addition to that, the operators should keep a safe distance from other workers and equipment since the machine’s large size and weight can be dangerous to people nearby. With this in mind, those professionals who are operating the machine cannot afford to become complacent while driving the machine in confined spaces or on bumpy surfaces in order to prevent the happening of collisions and other accidents.

Furthermore, another very important safety consideration is the correct and proper use of the machine’s controls and features. By correct usage I mean choosing the right settings for the material and compaction requirements, avoiding extreme speed or force that can cause both the machine and the surface being compacted to be damaged, and carefully starting and stopping the machine.

The most critical points shouldn’t be missed, that is the ones about the dead spots of the machine, and in these cases, mirrors or people acting as spotters should do their job to thus ensure safe operation. When operators comply with these safety rules/follow these safety guidelines, they can significantly decrease the risk of accidents and make the usage of the machine very safe and efficient at the same time.

Conclusion: Maximizing Efficiency with Roller Compactors

Highly efficient and adaptable, road rollers have numerous advantages for construction, landscaping, and a variety of other projects. To know how these instruments work and to properly select the kind of compactor machine that is in line with your requirements are the ways that you can obtain high-quality compaction and create well-built, durable, and stable surfaces that are going to last for a long time.

The cost and time effectiveness that comes along with the roller compactors’ efficiency—that is, the fact that the cost of the project is reduced and the project is accomplished within a short period—make them essential and invaluable to both experts and DIY enthusiasts.

Roller compactors are only good if you ensure that they are well-maintained and are worked on safely. Preventive maintenance, following the manual, and suitable storage are the first line of defense against sudden breakdowns and extended life expectancy.

In contrast, safety training, proper protective equipment, and careful operation reduce the likelihood of accidents and assure efficient use. By taking care of maintenance and safety, operators can acquire the maximum value and quality performance of their roller compactors.

As demonstrated by real-life examples and case studies, it is evident that roller compactors are the key factor in successfully carrying out various construction and landscaping tasks.

Such machines are used for various applications, including major highways, commercial buildings, and public parks, hence leading to the creation of highly firm, durable, and sufficiently stable surfaces and, in turn, the environment will enjoy a high quality and long life.

Unveiling the capability of roller compactors will lead to the attainment of extraordinary results and will also give you the chance to push forward your projects to another level.