Building requires a solid foundation. Compaction, which stabilizes and strengthens soil, asphalt, and gravel, is often neglected yet crucial. Your job may be compromised without proper compaction. Proper compaction equipment helps here. Knowing the distinctions between plate and roller compactors might be the difference between quality work and costly repairs.

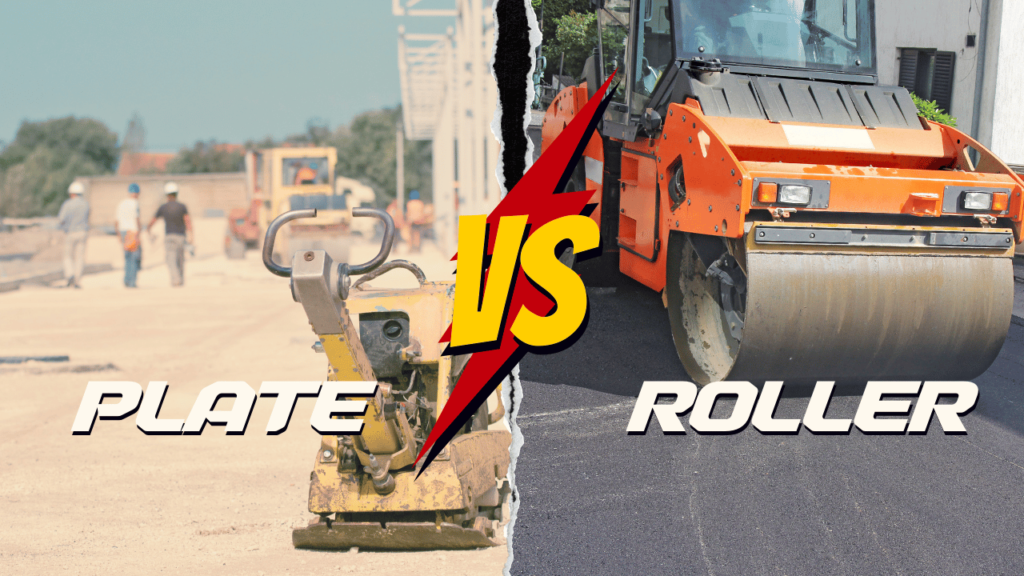

Imagine being on site in front of two terrifying machines: the plate compactor, designed for precision in small spaces, and the roller compactor, a massive machine able to tackle enormous areas. Each offers strengths and benefits specific to project concerns. Knowing what tools to use may make laying pavers or paving a city roadway magnificent. Explore these essential tools with us to make an informed decision that will boost your next project’s efficiency and effectiveness.

What are plate compactors?

Designed to crush asphalt and granular soils, plate compactors—also called vibratory plate compactors—are lightweight devices. Their components are a steel plate fast side-to-side or up and down coupled to a vibrating component. The downward push this vibration action creates on the surface compacts the soil particles.

Small-scale projects, including driveways, sidewalks, and patios, call for plate compactors. Projects involving road maintenance and landscaping also often call for them. Additionally, a common option among homeowners are plate compactors, as they are simple to use and maneuverable.

Characteristics of Plate and Roller Compactors:

- Lightweight and portable design

- Mechanism of vibration for compaction of soils

- Perfect for little jobs and garden maintenance

- Might be run by one individual.

- Having knowledge of Compactors for Roller Work

What are Roller Compactors?

Road rollers, often called roller compactors, are heavy-duty tools used to flatten vast stretches of asphalt or dirt. One or more metal rollers fastened to a frame—powered forward by an engine—make up them.

Large-scale building projects like road construction, landfills, and highway development all often need for roller compactors. They work as well for compaction of non-cohesive soils (sand and gravel) and cohesive soils (clay).

Characteristics of Roller Compactors:

- strong and heavy-duty architecture

- driven for effective compaction of large regions by an engine

- fit for both non-cohesive and cohesive soils

- One can run it under trained control.

Which is Best Plate or Roller Compactors?

The size and form of the compaction area as well as the kind of material being compacted determine whether a plate or roller compactor is best. Although they share the same goal, they have various qualities that qualify for diverse uses.

The main variations between plate and roller compactors will be discussed in this blog article along together with their perfect applications. This page will guide you in making a wise choice whether your interest is in compaction equipment or you are fresh to the building sector.

Check the Key Difference between Plate Compactors and Roller Compactors:

Variations in size and weight:

Plate compactors and roller compactors vary most obviously in weight and size. Little and light, plate compactors are simple to move and use in confined areas. Conversely, roller compactors are significantly heavier and bigger, so transporting need either a trailer or truck.

Composition Method of Compaction

Whereas roller compactors depend on shear force and weight for compaction, plate compactors compress soils using vibration. Plate compactors are thus more appropriate for minor compaction; roller compactors may do heavy-duty tasks.

Material Type

Granular soils and asphalt are ideal for kind of material plate compactors are designed for. Dealing with cohesive materials like clay makes them less effective. Conversely, because of their pure weight and power, roller compactors can manage both cohesive and non-coherent soils.

Surface Area

Plate compactors work best on smaller surfaces, as they are not designed for heavy-duty compaction. In contrast, roller compactors can effectively handle larger areas due to their size and design.

Compare the Work Efficiency between Roller Compactors and Plate Compactors:

Projects timetables are impacted by plate or roller compactors. Fast plate compactors find usefulness in small spaces. Their lightweight structure makes navigating difficult areas and tight turns simple. The agility of a plate compactor allows you to repair a driveway faster or create a new route without compromising quality.

By contrast, roller compactors cover more ground. To save time and prepare the ground, they roll over vast volumes of dirt in one pass on highways and other construction projects.

Furthermore, remarkable for surface area coverage are these devices. Plate compactors work well in small areas but badly in big ones because of their limited width. On a large fill site, you can have several passes, lengthening your workweek. Because of their huge drum widths, roller compactors can crush soil over greater distances without back-and-forth action. It follows: This machine guarantees constant compaction and accelerates parking lot grading.

Plate and roller compactors use operating energy quite differently. Smaller engines designed for power bursts rather than constant use allow plate compactors to lower fuel consumption. Effective gravel beds and asphalt patches might help you save money on little landscaping projects. Roller compactors need more energy to crush objects under pressure given their weight and size. For bigger projects, they might increase running costs; yet, their efficiency usually lowers rework, therefore boosting your bottom line.

Cost Analysis of Plate Compactor and Roller Compactor:

When choose between plate or roller compactors, initial investment counts. Renting or purchasing each variation has a very different price. For smaller operations and do-it-yourselfers, plate compactors, costing $50 to $100 a day, are perfect. But roller compactors’ capacity and longevity make them more costly. Depending on size and features, a new roller compactor may cost between $30,000 and over $200,000. Knowing your project extent will enable you to choose the least expensive solution.

Furthermore, affecting your choice are long-term running costs. Because its mechanics are simpler and there are less moving components, plate compactors often have less maintenance expenses. Roller compactors might need more frequent maintenance depending on their advanced systems for heavy operations. Lighter and less energy-consuming, plate compactors are more fuel-efficient than roller models. For builders overseeing many projects under tight deadlines, these savings might up quickly.

ROI is still another crucial consideration in this equipment comparison. For little projects like landscaping or patio paving requiring precision and agility without breaking the budget, a plate compactor might be better. Strong roller compactor may help surface density and durability if your projects include significant earthmoving for road construction or massive commercial structures, therefore saving time and money.

Long-term benefits and short-term costs will enable you to decide between plate and roller compactors depending on your needs. These financial considerations will help you to ensure that your equipment purchases provide results for major infrastructure projects and home landscaping.

What is the ideal space to use Plate or Roller Compactors?

Ideal Use Cases For Plate Compactors

Here are some common scenarios where plate compactors excel:

- Compact gravel and crushed stone for driveways, patios, and walkways

- Prepare a base for laying pavers or concrete slabs

- Compact trenches before filling them with pipes or utilities

Ideal Use Cases for Roller Compactors

Roller compactors are best suited for the following applications:

- Road building and repair projects

- Landfill construction and compaction

- Compacting cohesive soils like clay

- Non-cohesive soils (sand and gravel)

User Interface and Learning Curve – Which is the Best Plate Compactor and Roller Compactor?

Operator comfort affects plate vs. roller compactor productivity. Due to their light weight and size, plate compactors are simpler to operate in limited spaces. Heavy machinery novices may easily learn their fundamental design. Roller compactors need precision. Surface settings may confound controllers. Once one knows how a roller compactor works, its stability and efficiency on bigger areas are obvious.

Training is another element. Though simple, plate compactors need training for safe and effective use. Manufacturers provide fast safety and tool usage education. The diverse worksite applications of roller compactors may need additional training. Correct weight distribution or vibration settings improve performance and reduce errors.

Machine operation requires prudence. Plate compactor vibrations might cause pain after continuous usage, therefore wear worn gear. Operation visibility is critical at busy project sites where debris may block walkways or cause slips and falls. Roller compactors are speedier, therefore pedestrians and workers must be careful. Knowing these components allows for strong, productive well-being operations.

Environmental Impact of Plate Compactors and Roller Compactors:

Running noise is a factor in tool environmental impact. Job site plate compactors are lightweight and quiet. In houses and communities where noise annoys neighbors, this reduced noise level is essential. Roller compactors are too noisy for urban usage because to their size and engine power. Plate compactors may be ideal for uninterrupted fine-tuning.

Sustainability relies on fuel usage. Plate compactors are fuel-efficient and less demanding than roller compactors. Reduce fuel consumption and greenhouse gas emissions to save money in today’s ecologically conscious society. Roller compactors are ideal for roadwork and earthmoving, although their weight and power may need more fuel. Finally, balancing project needs with efficiency saves money and the environment.

Recycling is another major distinction between roller and plate compactors. With proper selection, plate compactors can aggregate gravel and asphalt for recycling or repurposing. Roller compactors may compress non-recyclable soil. Assessing how efficient and sustainable compaction methods meet your environmental goals is necessary. Material reuse in equipment reduces landfill waste.

Which One Is Right for You?

So, which compactor should you choose? Here are some factors to consider:

- The type of material you need to compact: If your project involves cohesive soils, a roller compactor would be the better option. For granular materials, a plate compactor would suffice.

- The size of the project: For small-scale projects, a plate compactor is more than enough. However, for larger areas, a roller compactor is the way to go.

- Your budget: Plate compactors are less expensive and require less maintenance compared to roller compactors. However, if you have a large project where heavy-duty compaction is needed, investing in a roller compactor might be a better long-term choice.

Conclusion

Finally, plate compactors and roller compactors are two different machines designed for specific applications. While plate compactors are best suited for small-scale projects and granular materials, roller compactors excel in larger areas and heavy-duty tasks.

When choosing between the two, consider the type of material, project size, and budget to make an informed decision that meets your needs. We hope this article has helped you understand the key differences between plate and roller compactors and identify their ideal use cases.