Mastering Compaction Work with Rollers Every Construction Professional Needs to Know

Introduction to the Importance of Compaction

In building, a good foundation is really vital. Whether you are developing roads, railroads, or large-scale infrastructure projects, compaction is an essential procedure guaranteeing the lifetime and durability of buildings. Good compaction reduces air spaces and raises soil density, therefore reducing future settling and improving load-bearing capacity. Professionals in construction, civil engineering, and infrastructure development must know the 4 Types of Rollers Commonly Used in Construction Projects and their purposes in compaction operations if they are to produce durable and strong projects.

Overview of Main Types of Rollers Used in Compaction

Regarding compaction, there is no one-size-fits-all fix. Various applications need different kinds of rollers to produce the best results. The following is a detailed summary of the several kinds of rollers employed in compaction operations:

- Smooth Drum Rollers

- Padfoot Rollers

- Pneumatic Tire Rollers

- Vibratory Rollers

Each type of roller has its own unique features and applications. Let’s take a closer look at each one and explore their specific uses and advantages.

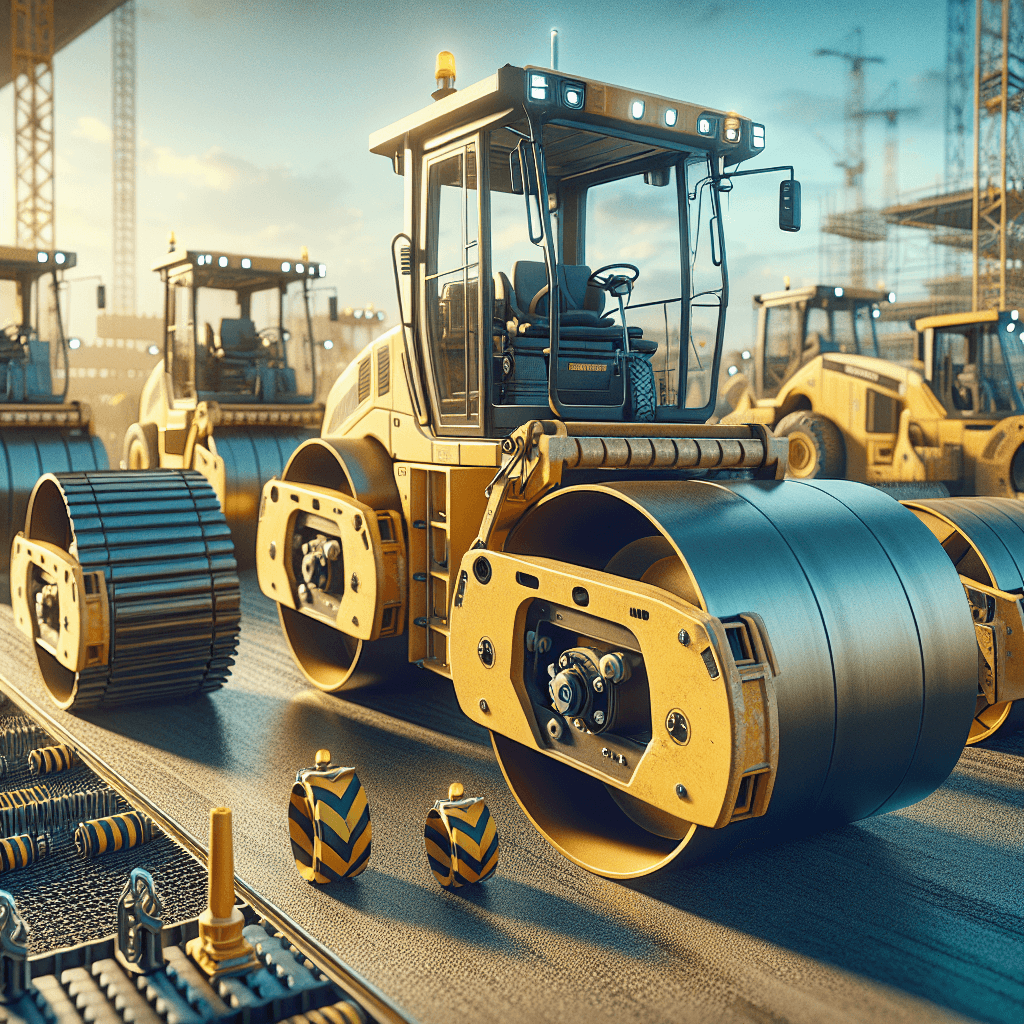

Smooth Drum Rollers

What are Smooth Drum Rollers?

Among the most often used rollers in the construction sector are smooth drum rollers. These rollers have a big, smooth steel drum at the front and occasionally at the rear that offers even compaction across the asphalt or dirt surface.

Uses and Applications

Compaction of granular soils like sand, gravel, and crushed rock calls for smooth drum rollers. In road building projects, they are also ideal for compaction asphalt layers. Their equal weight distribution and smooth surface provide a constant and dense compaction, therefore lowering the voids and weak point risk.

Advantages and Best Practices

Smooth drum rollers have mostly one benefit: their fast covering of big surfaces. With fewer passes, they may attain appropriate compaction levels and are quite efficient. Maintaining a consistent speed and avoiding abrupt pauses or rapid turns—which could cause unequal compaction—is crucial for best outcomes. Drum surface regular maintenance is also absolutely vital to avoid any damage that can compromise compaction quality.

Padfoot Rollers

What are Padfoot Rollers?

Padfoot rollers, also known as sheepsfoot rollers, feature a drum with rectangular or tapered pads (feet) on its surface. These pads penetrate deep into the soil, providing a kneading action that enhances compaction, particularly in cohesive soils.

Uses and Applications

Compaction clay, silt, and other cohesive soils is where padfoot rollers are most suited. Stable foundation construction depends on improved soil bonding, which the pads break up big clumps of and encourage. Large-scale infrastructure projects, including landfill sites and dam building, generally start their compaction process with these rollers.

Advantages and Best Practices

Padfoot rollers guarantee complete compaction even in thick soil layers via their kneading action. Maintaining a constant moisture level in the soil during compaction will help to produce the optimum results. Either too dry or too wet soils might affect compaction effectiveness. Combining padfoot rollers with smooth drum rollers can also help to produce more consistent compaction over the project.

Pneumatic Tire Rollers

What are Pneumatic Tire Rollers?

Pneumatic tire rollers, or rubber-tired rollers, are equipped with multiple tires that provide a kneading action to compact the soil or asphalt. The weight of the roller is distributed among the tires, which helps achieve a uniform compaction density.

Uses and Applications

These rollers can be applied on asphalt layers as well as on cohesive and granular soils. Usually used in road building projects, they help to produce a smooth and dense surface. The tires’ adaptability lets one make little changes in compaction pressure, which qualifies them for different compaction jobs.

Advantages and Best Practices

Better maneuverability and the possibility to efficiently compact irregular terrain are two benefits of pneumatic tire rollers. Tire pressure should be changed based on the type of material being compacted if one wants the best performance. Maintaining constant compaction quality depends partly on regular tire examination for any wear and tear.

Vibratory Rollers

What are Vibratory Rollers?

Vibratory rollers are equipped with a vibrating drum that enhances the compaction process by applying both static and dynamic forces to the soil or asphalt. This vibration helps the particles rearrange themselves in a denser configuration, leading to better compaction results.

Uses and Applications

Vibratory rollers are ideal for compacting granular soils, such as sand and gravel, as well as asphalt layers. They are widely used in highway construction, airport runways, and other large-scale infrastructure projects where achieving high compaction density is critical.

Advantages and Best Practices

Their capacity to reach high compaction density with few passes is the main benefit of vibratory rollers. The suitable frequency and amplitude settings depending on the material being crushed will help to enhance their efficacy. Moreover, constant functioning depends on frequent maintenance of the vibrating mechanism.

Case Studies of Successful Compaction Projects

Real-World Examples

To illustrate the effectiveness of different rollers in compaction work, let’s explore some real-world examples:

Example 1: Highway Construction in Texas

In a recent highway construction project in Texas, a combination of smooth drum rollers and vibratory rollers was used to achieve optimal compaction of the asphalt layers. The smooth drum rollers provided initial compaction, while the vibratory rollers ensured a dense and uniform surface. The result was a durable and smooth highway that met all safety and quality standards.

Example 2: Dam Construction in California

During the construction of a large dam in California, padfoot rollers were employed to compact the clay layers in the foundation. The kneading action of the padfoot rollers ensured thorough compaction, preventing any potential settling issues. This approach contributed to the stability and longevity of the dam structure.

Example 3: Airport Runway in Florida

For an airport runway project in Florida, pneumatic tire rollers were used to compact the asphalt layers. The flexible tires allowed for uniform compaction across the runway surface, ensuring a smooth and safe landing area for aircraft. The project was completed on time and within budget, thanks to the efficiency of the pneumatic tire rollers.

Technological Advancements in Compaction Equipment

Innovations in Roller Design

Recent advancements in compaction equipment have led to the development of rollers with enhanced capabilities. Some of these innovations include:

Intelligent Compaction Systems

Intelligent compaction systems use real-time data to monitor and adjust the compaction process. Sensors embedded in the rollers provide information on soil density, moisture content, and compaction progress, allowing operators to make informed decisions and achieve optimal results.

Hybrid Rollers

Hybrid rollers combine the features of different roller types, offering versatility and efficiency. For example, a hybrid roller may feature both smooth drum and vibratory mechanisms, allowing it to handle a wide range of compaction tasks with ease.

Eco-friendly Rollers

With a growing emphasis on sustainability, manufacturers are developing eco-friendly rollers that reduce emissions and fuel consumption. These rollers are equipped with energy-efficient engines and advanced hydraulic systems, making them environmentally friendly without compromising performance.

Impact on Efficiency and Sustainability

The most recent developments in compaction equipment have greatly raised construction project sustainability and efficiency. For instance, intelligent compaction systems cut the required passes to reach desired compaction levels, therefore saving time and money. With their adaptability, hybrid rollers let builders handle several compaction jobs with one machine. Eco-friendly rollers lower carbon footprints and save energy, so helping to contribute to a better building sector.

Practical Tips for Selecting the Right Roller

Assessing Project Requirements

Thoroughly evaluating the project requirements will help one choose a roller for a certain compaction operation. Think through elements including project size, kind of soil, and desired compaction density. Different rollers are appropriate for different uses; however, knowing the particular requirements of your project will enable you to decide with knowledge.

Evaluating Roller Features

Take the time to evaluate the features and capabilities of different rollers. Look for rollers with adjustable settings, such as frequency and amplitude, to ensure they can be tailored to the material being compressed. Consider the maneuverability and ease of operation of the roller, as these factors can impact productivity and compaction quality.

Consulting with Experts

If you are not sure which roller is best for your project, consult with industry experts. Reach out to manufacturers, suppliers, or experienced contractors who can offer valuable insights and recommendations based on their expertise. Their expertise can help you make the right choice and achieve optimal compaction results.

Conclusion

A basic feature of building and infrastructure development is compaction, hence, selecting the correct roller for the task is absolutely important. Understanding the several kinds of rollers that are available and their particular applications, benefits, and best practices will help civil engineers, builders, and infrastructure developers to guarantee the success of their projects.

Every kind of roller—from smooth drum rollers to padfoot rollers, pneumatic tire rollers, and vibratory rollers—offers special advantages and uses. Following sensible advice for choosing the correct roller and keeping current with the most recent technical developments in compaction equipment will help you to provide effective and environmentally friendly compaction results.

Share your knowledge and experiences with the building community so that we may keep creating a better future with long-lasting infrastructure. Subscribe to our newsletter or get in touch with our team of professionals to get further information and tailored recommendations on compaction equipment. Working together, we can master compaction and lay a strong basis for success.